The first day of Makino Corp.’s two-day 2017 Die/Mold Technology Expo included technology seminars, economic prognosticators, and demonstrations on more than 23 state-of-the-art machines at the company’s U.S. headquarters in Auburn Hills, Mich.

The company also unveiled a new vertical machining center for true 5-axis continuous processing, the V80S. The high-precision VMC evolved from the 3-axis Vi series and boasts an updated spindle and titling/rotating axis unit that supports tighter tolerances and decreased machining and polishing times. Designed for high-speed finishing of multifaceted, 3-D contours, the V80S cuts cycle times and reduces handwork in complex specialty dies and molds, according to Makino vertical product line manager Bill Howard.

“Now more than ever, mold manufacturers are struggling to meet demands for the utmost quality and accuracy while managing capacity constraints. This is why a new level of 5-axis machine performance is essential in today’s market,” said Howard. “The V80S was designed to meet these accuracy requirements, provide the finest finishes, maintain tight tolerance and increase productivity to boost capacity. Its lightweight, 20,000-rpm spindle is ideal for high-speed finish machining of dies and molds.”

The V80S can accommodate workpiece sizes up to 1500mm by 1200mm by 550mm (59" × 47.24" × 21.65") and weighing up to 2500 kg (2.75 tons), such as automobile door inner panels and front grilles. The 1300mm (51.18") X, 1000mm (39.37") Y and 600mm (23.62") Z axes impart swift movements with rapid traverse rates of 58,000mm/min (228.34 ipm) and cutting feedrates of 40,000mm/min (1575 ipm). The A-axis of the V80S tilts at ±30°, “wide enough to machine holes for an angular pin,” and the C-axis rotates at ±60°, ensuring that the tool tip can be positioned to provide optimum contact with the workpiece. The result, according to Howard, is extended tool life, outstanding surface finishes and reduced post-processing handwork.

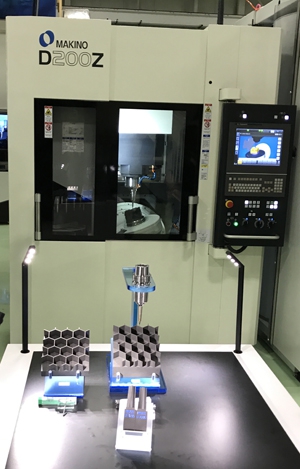

Another new machine, the D200Z 5-axis vertical machining center, was only at the prototype stage at IMTS16, but is now available and was being demonstrated at the expo. “The speed and precision of the D200Z supply a unique foundation for responsive high-speed cutting and outstanding surface finishes that reduce or eliminate handwork,” said Howard. The machine has a 30,000-rpm spindle and integral direct-drive table. It accommodates workpiece sizes up to 300mm (11.81") in diameter and 210mm (8.27") tall with weight up to 75 kg (165.34 lb). The 350mm (13.78") X, 300mm (11.81") Y and 250mm (9.84") Z axes travels provide rapid traverse and cutting feedrates of 60m/min (2362 ipm). The D200Z has also adopted a lightweight B-axis tilting structure with 180° (0 to +180°) of tilt capability at 100 rpm. Both the B-axis and rotational C-axis (360° degrees continuous at 150 rpm) feature direct-drive motors.

Another new machine, the D200Z 5-axis vertical machining center, was only at the prototype stage at IMTS16, but is now available and was being demonstrated at the expo. “The speed and precision of the D200Z supply a unique foundation for responsive high-speed cutting and outstanding surface finishes that reduce or eliminate handwork,” said Howard. The machine has a 30,000-rpm spindle and integral direct-drive table. It accommodates workpiece sizes up to 300mm (11.81") in diameter and 210mm (8.27") tall with weight up to 75 kg (165.34 lb). The 350mm (13.78") X, 300mm (11.81") Y and 250mm (9.84") Z axes travels provide rapid traverse and cutting feedrates of 60m/min (2362 ipm). The D200Z has also adopted a lightweight B-axis tilting structure with 180° (0 to +180°) of tilt capability at 100 rpm. Both the B-axis and rotational C-axis (360° degrees continuous at 150 rpm) feature direct-drive motors.

The D200Z at the expo was configured with a graphite machining package to demonstrate its ability to quickly and accurately cut graphite electrodes. Howard showed two graphite electrodes to visitors. They were almost identical, except one was labelled as having been made on a 3-axis machine and the other on the 5-axis D200Z. According to Howard, the former took 66 minutes to complete; the latter was machined in just 5 minutes.

Makino’s biennial Die/Mold Technology Expo concludes today.

Related Glossary Terms

- 3-D

3-D

Way of displaying real-world objects in a natural way by showing depth, height and width. This system uses the X, Y and Z axes.

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

- polishing

polishing

Abrasive process that improves surface finish and blends contours. Abrasive particles attached to a flexible backing abrade the workpiece.

- rapid traverse

rapid traverse

Movement on a CNC mill or lathe that is from point to point at full speed but, usually, without linear interpolation.

- tolerance

tolerance

Minimum and maximum amount a workpiece dimension is allowed to vary from a set standard and still be acceptable.