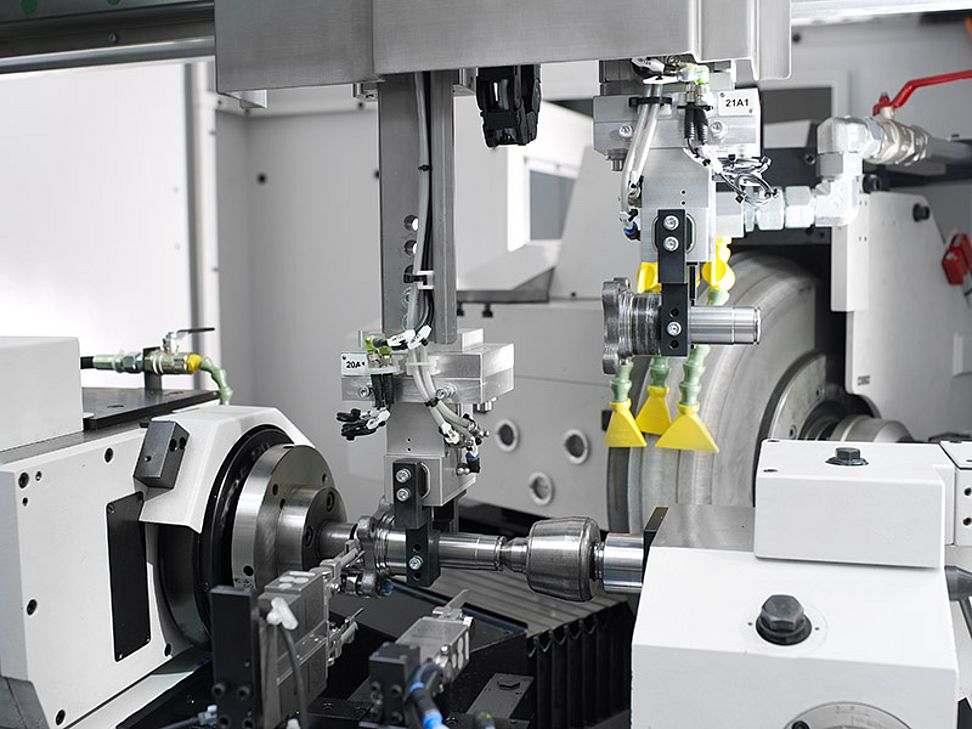

The EMAG Group is expanding its technology range in the field of grinding with cylindrical grinding technology from Weiss. “We are extending our range of products in the area of high-output and high-precision cylindrical grinders with grinding technology from Weiss,” explains Dr. Guido Hegener, managing director of EMAG Maschinenfabrik GmbH. “Cylindrical grinding is particularly important at the end of the process chain, when a large part of the added value has already been transferred to the part. That is why it is very important for us to offer our customers the best solutions in this area. The expertise and machines from Neckartailfingen significantly expand our range of solutions. Resulting in even more attractive offerings available to our customers.”

Over the past few years, CNC-Technik Weiss has made a name for itself as a successful developer of cylindrical grinders. Founded in 1993, the company built this expertise by performing maintenance and modernization work on Karsten cylindrical grinders. The high quality service provided by the company quickly led to growth in customer base and resulted in demand for in-house production solutions, leading to the development of its own cylindrical grinders. This marked the birth of Weiss CNC cylindrical grinders.

“I’m excited to have found a new partner in the EMAG Group, that allows me to put my visions for our business into practice,” explains Bernd Weiss, current and former managing director of the company. “Our massive growth at the Neckartailfingen plant has brought us to our capacity limits. As part of the EMAG Group, completely new opportunities are opening up for our products. We now have access to broad knowledge and support from the group, which will allow us to accelerate the development of new machines. Our customers will continue to receive the quality they expect from us, and will also benefit from the EMAG Group’s extensive service network – a win-win situation for all parties involved.”

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- cylindrical grinding

cylindrical grinding

Grinding operation in which the workpiece is rotated around a fixed axis while the grinding wheel is fed into the outside surface in controlled relation to the axis of rotation. The workpiece is usually cylindrical, but it may be tapered or curvilinear in profile. See centerless grinding; grinding.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.