Thanks to a change in the laser technology employed by a new noncontact measuring system, shop personnel who set miniature tools will stop seeing red.

The NC4+ Blue on-machine tool-setting system is the first of its kind to feature a blue laser, according to West Dundee, Illinois-based Renishaw Inc. The patent pending blue laser technology produces a shorter wavelength than the red laser sources used by conventional noncontact tool setters, reducing diffraction and allowing better control of the laser beam geometry, said Dave Bozich, Renishaw’s machine tool business manager.

“When you don’t have good control of the geometry, you get divergence of the beam as it travels from the transmitter to the receiver,” he said.

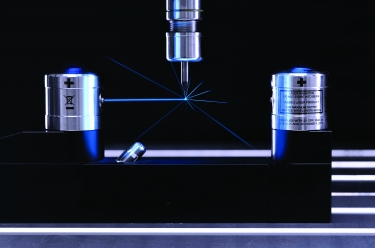

Featuring blue laser technology, the NC4+ Blue on-machine tool-setting system accurately measures very small tools. Image courtesy of Renishaw

As a result, the beam increases in diameter and loses energy on the trip to the receiver. In contrast, the blue laser beam, which is 25% to 30% smaller in diameter, retains the diameter and energy that it had exiting the transmitter, he said. This makes NC4+ Blue especially well suited to measure very small tools. These delicate tools can be damaged by contact tool setters. However, he said red laser systems historically have had difficulty measuring the length of tools 0.004" or less in diameter. That’s not the case with NC4+ Blue. It enables accurate measurement of tools half the size of those that can be accurately measured by conventional red laser systems, Renishaw reports.

In addition, the company states that its blue laser alternative minimizes tool-to-tool measurement errors when machining with a wide range of cutting tools. Consider a situation in which tools in a carousel range from 0.004" to 0.125" in diameter. To deal with this range of sizes, Bozich said CNC programmers add “experience values” to software. As the name suggests, these are experienced-based factors meant to increase the accuracy of results when measuring tools with particular diameters. With NC4+ Blue, though, these “fudge factors” aren’t needed, he said.

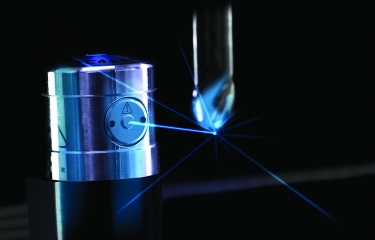

NC4+ Blue enables accurately setting tools even when there’s a large difference between the diameters of the tools. Image courtesy of Renishaw

“When you have tight control and better geometry of the laser beam,” he said, “you can set tools very accurately even when there’s a big difference between the diameters of the tools.”

NC4+ Blue also features a new measurement mode to handle the presence of coolant during the setting process. Conventional laser systems take measurements when a tool breaks the beam. But dripping coolant can break the laser beam too, causing an inaccurate reading and necessitating a retry of the measurement process. So Renishaw offers a different measurement approach in which the tool blocks the beam to begin with and then moves out of the way, with the measurement being taken the instant the light no longer is blocked. This method virtually eliminates coolant’s ability to adversely affect the measurement, he said.

Shop personnel can view historical tool data captured by NC4+ Blue using the latest version of Renishaw’s Reporter app, which can be installed on a machine’s control or a tablet that plugs into the machine. The app lets users perform tasks, such as monitoring how long a particular tool has been in cycle, as well as export key tool metrics for use in other software and control systems.

Although NC4+ Blue is not yet commercially available, Renishaw reports that it has demonstrated the technology to select customers. After introducing the product next month at the EMO exhibition in Hanover, Germany, the company will start selling it in winter at a price comparable to that of the noncontact laser technology Renishaw already offers.

With the system soon to be available at a competitive price point, potential users should have no reason to be blue about this tool-setting option.

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.