Tips for a manual milling machine

Tips for a manual milling machine

In my October column, I explained how the design of manual milling machines could be improved. This month, I share some tips for enhancing the operation of a manual mill.

In my October column, I explained how the design of manual milling machines could be improved. This month, I share some tips for enhancing the operation of a manual mill:

- Get an indicator with a vertical dial. This beats craning your neck like a bird hunting a worm all around the mill when zeroing a part.

- For tramming the head, make several long indicator holder bars to sweep a larger arc. If you have trouble indicating a bore you think should be round, check the head tram condition. Typically, you would see a longer direction or equal but mismatched numbers. If the head is out, you're out on your head.

![]()

Using an indicator with a vertical dial beats craning your neck when zeroing a part. All images courtesy T. Lipton.

![]()

- Button-type indicators slide over the T-slots easier than a test indicator when tramming.

- Use a high-quality combination square on the mill. You will be surprised how close you can get. I checked one of my combination squares against a master square comparator and was happy to find it was within 0.002 " of square at 10 " off the surface plate.

- Prior to discovering special-toothed wedges, I used 5/8 " dowel pins as backstops in the mill like everybody else. But the wedges fit tightly in a T-slot of any width. You can easily vary the height and even use them for special clamping jobs.

![]()

Special-toothed wedges are effective as backstops in a mill.

![]()

- Cut the long shanks off your drill chucks. The R-8 collet is only 1 " long inside. How much shank do you need up there? Consider all the time you spend cranking the knee up and down to get the chuck in and out of that long shank. For that matter, lose the R-8 shank on your drill chuck. If you have a 5/8 "-dia. straight shank on the drill chuck, you will save hundreds of collet changes a year if you buy a few common-sized endmills with the same shank size as the drill chuck.

- Buy two drill chucks with different diameter shanks on them. This allows you to save time on tool changes when you have the same shank diameter as your cutting tools.

- Don't put an endmill in a quick-change drill chuck. This is tempting at times but is a pure rookie move. If the endmill chatters for a billionth of a second, the chuck loosens and all hell breaks loose!

![]()

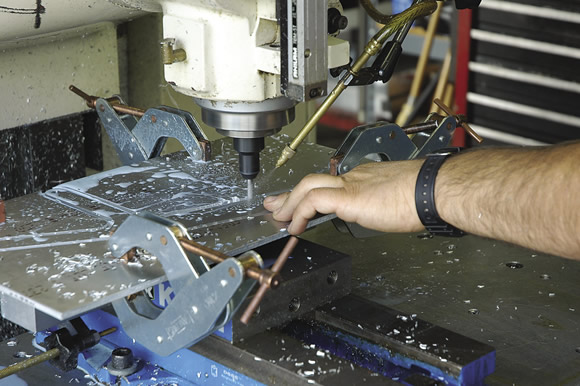

Carefully hold your hand on the part when using tricky or dicey setups because your hand will detect a part shifting before your eye will.

![]()

- Remove the drawbar every so often and put a drop of oil or light assembly lube on the threads. You should be able to spin this with your pinkie. If it doesn't spin freely, get a new one.

- Use the spindle motor to rapid traverse the collet out after you break it loose with a wrench. Hold only the drawbar lightly with your fingers and catch the collet as it falls.

- Better yet, invest in a power drawbar, which has a quick payback. Unless you use a right-angle thread on a daily basis, the argument about slow changeover doesn't hold water. Once you have tried a power drawbar, you will wonder how you managed without it. No more smashed fingers or wrenches ratting over your head.

![]()

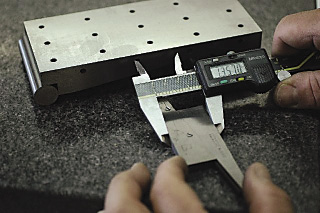

Always caliper a stack of gage blocks to confirm your math.

![]()

- Hold your hand on the part when using tricky or dicey setups. Your hand will detect a part shifting before your eye will, giving instant feedback to the other hand that's cranking the feed handle.

- Get comfortable using a sine bar. These are simple-to-use, deadly accurate tools for setting angles. The sine bar should span the ways of a standard milling vise. Don't think of these tools as too precious for everyday work. Smaller sine bars are handy for manual mill work. One with a 3" to 5" center distance is ideal.

- Use a sine bar to set head or vise angles. You can also sweep the face of the bar just like you would when tramming the head to set a precision angle.

- Use a gage pin to quickly set your sine bar. This can eliminate stack-up math errors using gage blocks. As a safety measure, always caliper a stack of blocks to confirm your math.

Use this Sine Bar calculator to save time on the shop floor!