By packaging both turning and milling functions in a single machining center, machine tool builders believe they’ve hit on a winning combination that can boost part quality while also slashing cycle times, space and costs.

Efforts to include more than one machining capability in a single machine go back a couple of decades, said Errol Burrell, machining center product specialist for Okuma America Corp., Charlotte, N.C. Why the interest in multitask machines?

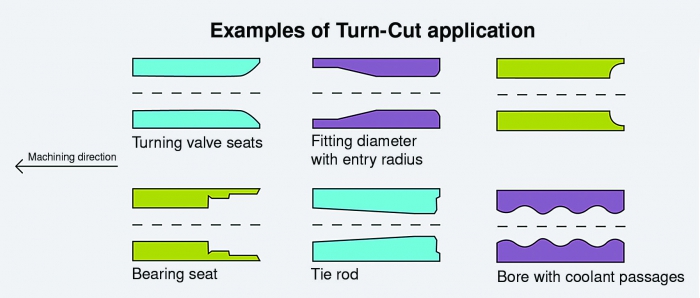

Turn-Cut is a programming option that enables a horizontal machining center to create surfaces that taper, arc or change in other ways along the Z-axis of a workpiece. Image courtesy of Okuma America.

“Work space is at a premium,” said Burrell, whose company offers Turn-Cut, a programming option that adds turning capabilities to a horizontal machining center. “So, if you have a machine that does both milling and turning, now you’ve got just one machine taking up a smaller space [than two machines].”

Combining turning and milling in one machine also improves machining accuracy by allowing users to keep parts clamped in place, thereby preventing possible stack-up errors.

Additionally, splitting up milling and turning among multiple machines can require users to make four or five setups, said Simon Knecht, NAFTA region sales manager for Germany-based STAMA Maschinenfabrik GmbH. Charlotte-based Chiron America Inc. sells the company’s machines. STAMA has been building its integrated vertical milling and turning centers, called mill-turn machines, since 1999. “On the mill-turn, in the best case, you can finish in one or two clampings.”

Multiple setups on separate turning and milling machines require parts to be handled multiple times, thereby lengthening the production process, said Kelsey Hadley, a STAMA product specialist. “But by combining operations on the mill-turn machine, we can reduce the amount of part handling and the amount of nonproductive machining time.”

STAMA’s MT 8 Twin offers integrated turning and double-spindle milling. Image courtesy of Chiron Group.

Hadley said mill-turn machines are a good choice for making complex parts, such as automatic transmissions, that require both milling and turning. Mill-turn candidates mentioned by Knecht include turbocharger parts, as well as bearing and turbine housings.

As for Turn-Cut, which requires the addition of scales and software to a conventional HMC, Burrell recommends it for large fabrications and things like castings for 2'-dia. (0.61m) pipes used by the oil and gas industry. Turn-Cut could be used to turn a feature like a groove or taper at the end of a pipe, as well as thread the end. “Anything you can do on a lathe, you can do with Turn-Cut,” Burrell said.

He added, however, that Turn-Cut may not be the best choice for components with diameters smaller than 3" (76.2mm). The smaller the component, he said, the less likely it will be that Turn-Cut can produce an adequate surface finish.

Generally speaking, multitask machines incorporate more components and features than their conventional counterparts. This makes them more expensive, Knecht said.

Knecht insists, though, that mill-turn programming is not more complicated than it would be for a person working with a standard lathe and milling machine. “You program your 3-axis milling operations like you would a standard milling machine and your turning operations like you would a turning machine. And then all you are doing is combining these two programs into one,” he said.

Turn-Cut users aren’t faced with any special challenges either, according to Burrell. When the time comes for turning, they simply switch to Turn-Cut mode. Then they proceed as they would if they were machining a part with a conventional lathe.

Contact Details

Contact Details

Related Glossary Terms

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- conventional milling ( up milling)

conventional milling ( up milling)

Cutter rotation is opposite that of the feed at the point of contact. Chips are cut at minimal thickness at the initial engagement of the cutter’s teeth with the workpiece and increase to a maximum thickness at the end of engagement. See climb milling.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- lathe

lathe

Turning machine capable of sawing, milling, grinding, gear-cutting, drilling, reaming, boring, threading, facing, chamfering, grooving, knurling, spinning, parting, necking, taper-cutting, and cam- and eccentric-cutting, as well as step- and straight-turning. Comes in a variety of forms, ranging from manual to semiautomatic to fully automatic, with major types being engine lathes, turning and contouring lathes, turret lathes and numerical-control lathes. The engine lathe consists of a headstock and spindle, tailstock, bed, carriage (complete with apron) and cross slides. Features include gear- (speed) and feed-selector levers, toolpost, compound rest, lead screw and reversing lead screw, threading dial and rapid-traverse lever. Special lathe types include through-the-spindle, camshaft and crankshaft, brake drum and rotor, spinning and gun-barrel machines. Toolroom and bench lathes are used for precision work; the former for tool-and-die work and similar tasks, the latter for small workpieces (instruments, watches), normally without a power feed. Models are typically designated according to their “swing,” or the largest-diameter workpiece that can be rotated; bed length, or the distance between centers; and horsepower generated. See turning machine.

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

- turning machine

turning machine

Any machine that rotates a workpiece while feeding a cutting tool into it. See lathe.