Water Jet Sweden AB introduced its Fine Abrasive Water Jet (FAWJ) process a decade ago to meet industry’s need to make narrow, high-precision cuts in hard materials. The company developed the technique for a specially designed waterjet machine used to produce microparts.

Recently, Water Jet Sweden introduced the FAWJ Micro Head package. It is for users of the company’s standard machines—the X-Series and Premium lines—who want to make highly precise, narrow cuts but don’t need to meet extremely tight tolerances, such as those often required for manufacturing microscale components.

Traditional abrasive waterjets typically produce a kerf of 0.8mm to 1.0mm (0.031" to 0.039"). The Micro Head package lets users make cuts as narrow as 0.3mm (0.012"). Positioning accuracy is ±0.05mm/m (0.002"), and repeatability is ±0.025mm (0.0010").

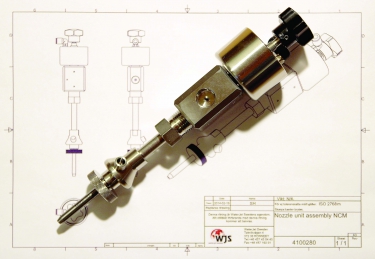

The cutting head for Water Jet Sweden’s Micro Head package. Image courtesy of Water Jet Sweden.

X-Series and Premium tables range from 1m × 1m to 4m × 2m (3.3'×3.3' to 13.1'×6.6').

Water Jet Sweden originally developed its NCM 10 (“Micro”) machine for the FAWJ process and the production of microparts. The NCM 10/Micro Head combination reportedly produces a 0.2mm kerf, has positional accuracy of ±0.01mm (0.0004") and repeatability of ±0.008mm (0.0003").

The FAWJ process is suitable for manufacturing precision mechanical devices, electronics and biotechnology applications, as well as industries that need to cut hard materials to tight tolerances, the company reports.

“Since the introduction of the Micro machine and growing familiarity among customers with the process, the company has seen increased demand for more-general use of fine-abrasive waterjet cutting,” said Water Jet Sweden Chief Marketing Officer Klas Wallström.

For more information about Water Jet Sweden AB, Ronneby, Sweden, visit www.waterjetsweden.com or call +46 457-45-54-40.

Related Glossary Terms

- abrasive

abrasive

Substance used for grinding, honing, lapping, superfinishing and polishing. Examples include garnet, emery, corundum, silicon carbide, cubic boron nitride and diamond in various grit sizes.

- kerf

kerf

Width of cut left after a blade or tool makes a pass.

- waterjet cutting

waterjet cutting

Fine, high-pressure (up to 50,000 psi or greater), high-velocity jet of water directed by a small nozzle to cut material. Velocity of the stream can exceed twice the speed of sound. Nozzle opening ranges from between 0.004" to 0.016" (0.l0mm to 0.41mm), producing a very narrow kerf. See AWJ, abrasive waterjet.