The expression “There’s more than one way to skin a cat” certainly applies to machining. A young programmer in our shop is constantly being run in circles by the whims of those in authority. Newcomers are in a difficult position; they not only lack experience, they generally want to please everybody.

For example, there are numerous ways to apply edge dressings to a part, and some work better than others. Presented here are methods that may make it easier to apply these common features.

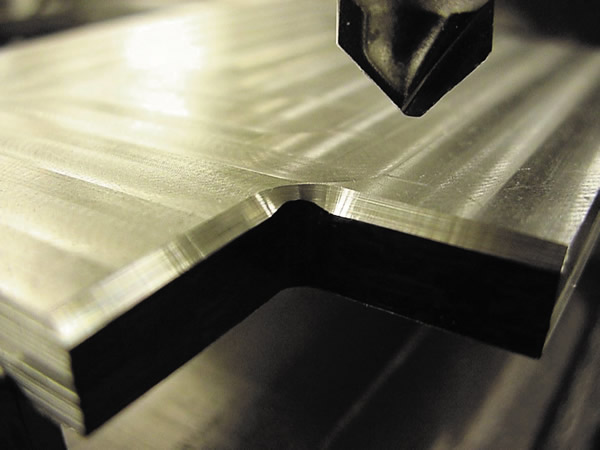

Shown is an inconsistent chamfer on an inside radius. This was because the Z height of the chamfering tool wasn’t set correctly. All images courtesy J. Harvey.

Chamfering is not as easy as it looks on a computer. The point of a sharp chamfering tool does not cut well and will generate a burr if programmed to cut on center around the profile of a part. This is because not much chip clearance is available at the end of a pointed chamfering tool and the cutting speed at the tip of a pointed tool is, theoretically, zero. Also, the tool tip may not be precisely sharp.

For a chamfering tool to cut cleanly, the tool tip must be offset from the profile. In a new version of the CAM software I use, a chamfering tool can now be offset to cut a clean profile.

If you offset a chamfering tool to cut cleanly, the depth of the tool must be correct. If the depth is not correct, the tool can produce inconsistent chamfers on the inside radii. This can be overcome with thoughtful planning. However, when it boils down to trivial features, I don’t like to think too much. I prefer to let the computer do the thinking.

For most chamfering, use a ballnose or hognose endmill and program the chamfer with a 3D cut. Using this method, the computer does all the thinking for you and you don’t have to worry about burrs, offsetting the tool or inconsistent chamfers. The only thing you have to concern yourself with is choosing a cutter with a radius smaller than the smallest inside radius of the part. The downside is that chamfers may take a bit longer to cut because you are taking multiple passes to create the chamfer. I usually go full throttle when chamfering this way.

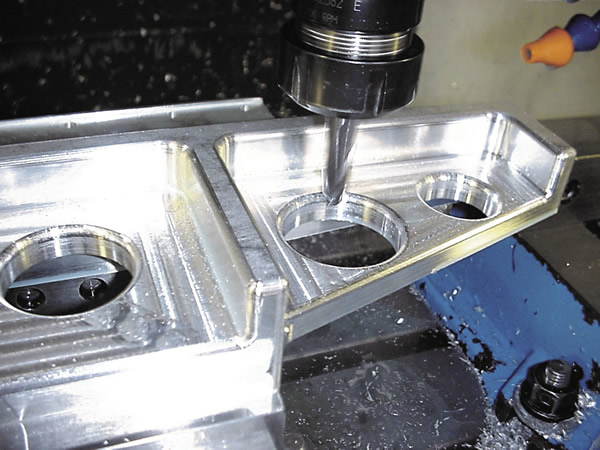

A ballnose endmill cuts an edge radius around a hole using the 3D method.

The programmer I previously mentioned got into hot water using this method. A component needed a 0.1" chamfer around the perimeter and the center window. The customer was waiting for the part and would frequently go to the machine to check on its progress.

The chamfer operation was painfully slow, and the customer was getting agitated. Afterward, I told the well-intentioned programmer that he’d better push hard on the accelerator if he was going to chamfer using the 3D method. The parameters he was using were 7,000 rpm, a 100-ipm feed rate and a 0.002" step-over, which collectively resulted in the operation taking 29 minutes. The biggest mistake is the small step-over moves, which are set in the G code and can’t be adjusted at the machine. In hindsight, it’s easy for me to second-guess his settings, but I would have chosen 10,000 rpm, a 300-ipm feed and a 0.006" step-over, resulting in the operation taking 3.8 minutes.

Cut edge radii using the 3D method. You can use a radius tool to radius edges, but radius tools are a little tricky to setup and adjust. I prefer using a ballnose endmill to cut soft material, such as aluminum, and a hognose endmill to cut steel. That way the computer does all the thinking and little, if any, adjustment is needed. A hognose endmill cuts with less pressure than a ballnose, because less cutting edge contacts the material.

With fillets and chamfers being easy to apply with CAD software, designers routinely add them to their solid part models because they look “pretty.” Many don’t realize that chamfers and radii are much more time-consuming to cut than to model.

Related Glossary Terms

- burr

burr

Stringy portions of material formed on workpiece edges during machining. Often sharp. Can be removed with hand files, abrasive wheels or belts, wire wheels, abrasive-fiber brushes, waterjet equipment or other methods.

- chamfering

chamfering

Machining a bevel on a workpiece or tool; improves a tool’s entrance into the cut.

- chamfering tool

chamfering tool

Cutter or wheel that creates a beveled edge on a tool or workpiece.

- chip clearance

chip clearance

In milling, the groove or space provided in the cutter body that allows chips to be formed by the inserts.

- clearance

clearance

Space provided behind a tool’s land or relief to prevent rubbing and subsequent premature deterioration of the tool. See land; relief.

- computer-aided design ( CAD)

computer-aided design ( CAD)

Product-design functions performed with the help of computers and special software.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- cutting speed

cutting speed

Tangential velocity on the surface of the tool or workpiece at the cutting interface. The formula for cutting speed (sfm) is tool diameter 5 0.26 5 spindle speed (rpm). The formula for feed per tooth (fpt) is table feed (ipm)/number of flutes/spindle speed (rpm). The formula for spindle speed (rpm) is cutting speed (sfm) 5 3.82/tool diameter. The formula for table feed (ipm) is feed per tooth (ftp) 5 number of tool flutes 5 spindle speed (rpm).

- endmill

endmill

Milling cutter held by its shank that cuts on its periphery and, if so configured, on its free end. Takes a variety of shapes (single- and double-end, roughing, ballnose and cup-end) and sizes (stub, medium, long and extra-long). Also comes with differing numbers of flutes.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- step-over

step-over

Distance between the passes of the toolpath; the path spacing. The distance the tool will move horizontally when making the next pass. Too great of a step-over will cause difficulty machining because there will be too much pressure on the tool as it is trying to cut with too much of its surface area.