Dear Doc: We grind forms into steel and nickel alloys. We use a plunge diamond roll to dress the form into the wheel with a unidirectional +0.8 speed ratio to make the wheel sharp. However, when we need to dress in a new 1A1 wheel, it takes forever. If we increase our plunge speeds, the dressing operation starts chattering. Is there a way to speed this up?

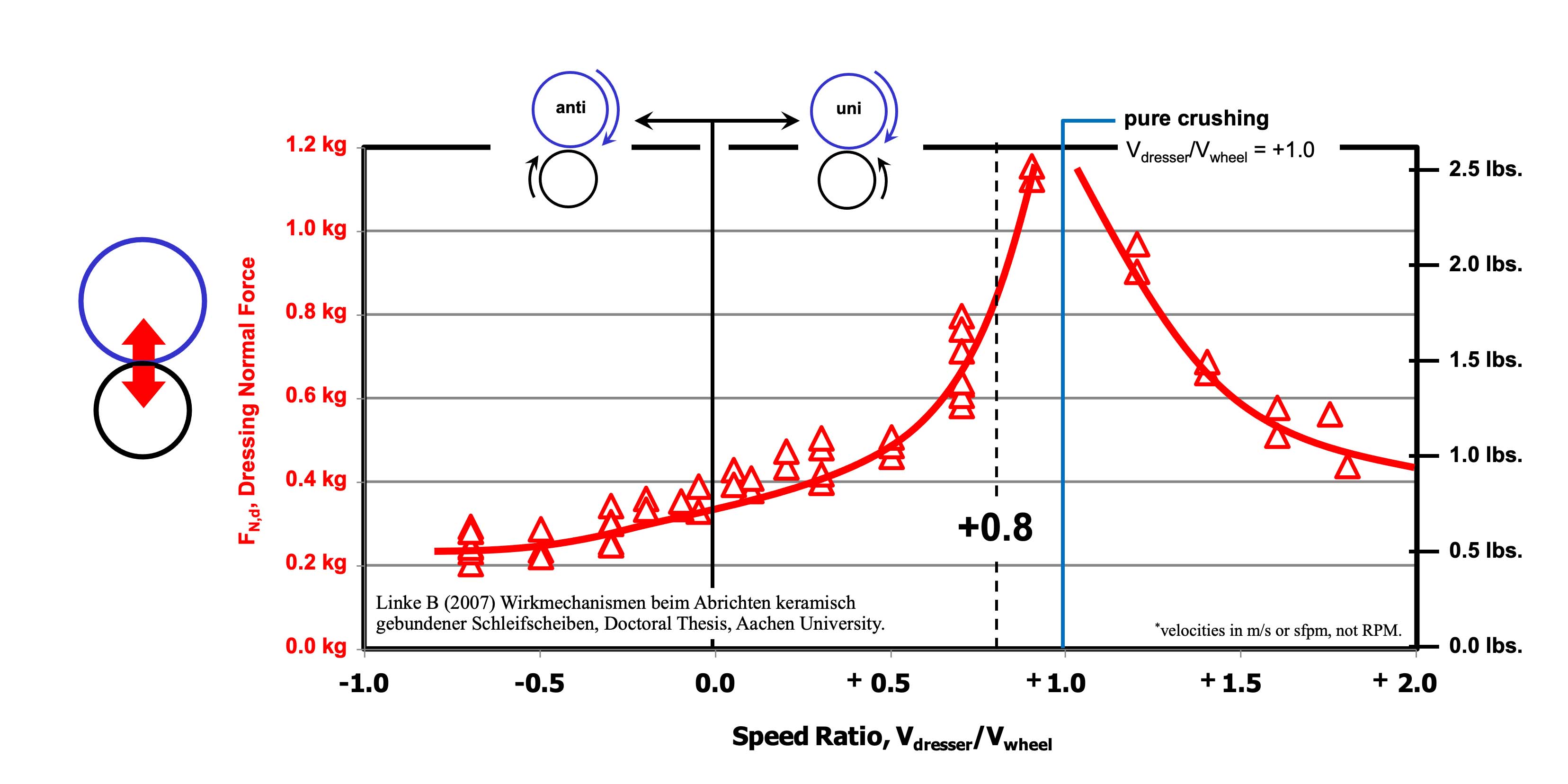

The Doc replies: Yes. Simply switch the direction of rotation of your dressing roll to dress anti-directional during that dressing-in portion — in your case, with a Vdresser/Vwheel = -0.8 speed ratio. This can reduce dressing forces by about one-sixth of what they were originally, allowing you to plunge faster and get that wheel dressed in quicker without any increased risk of chatter.

Just make sure to go back to your regular Vdresser/Vwheel = +0.8 ratio before going to grind. That’s because going anti-directional makes your wheel dull, and you’re doing the right thing in going unidirectional to make the wheel sharp for grinding. Leave around 0.2 mm depth on the wheel before switching back to unidirectional to clear away that residual dullness on the wheel.

Also, make sure you have a coolant nozzle on the other side of the dresser. Diamonds fall apart above 700 degrees Celsius, and diamond rolls aren’t cheap.

If you want to get fancy, you can slow down the grinding wheel speed during dressing in using the unidirectional mode. This will decrease the “cutting stiffness” and allow you to plunge even faster. (The reasons for this are complicated, but suffice to say this option can be traced to the realm of hardcore vibration experts. Bottom line: It often works.) Just make sure to switch back to your regular wheel speed when doing the final dress before grinding. (Remember the old machinist’s adage: “Dress and grind at the same wheel rpm.”)

I’ve seen companies cut dressing-in times from 40 to 5 minutes.

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- chatter

chatter

Condition of vibration involving the machine, workpiece and cutting tool. Once this condition arises, it is often self-sustaining until the problem is corrected. Chatter can be identified when lines or grooves appear at regular intervals in the workpiece. These lines or grooves are caused by the teeth of the cutter as they vibrate in and out of the workpiece and their spacing depends on the frequency of vibration.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- dressing

dressing

Removal of undesirable materials from “loaded” grinding wheels using a single- or multi-point diamond or other tool. The process also exposes unused, sharp abrasive points. See loading; truing.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- grinding wheel

grinding wheel

Wheel formed from abrasive material mixed in a suitable matrix. Takes a variety of shapes but falls into two basic categories: one that cuts on its periphery, as in reciprocating grinding, and one that cuts on its side or face, as in tool and cutter grinding.

- stiffness

stiffness

1. Ability of a material or part to resist elastic deflection. 2. The rate of stress with respect to strain; the greater the stress required to produce a given strain, the stiffer the material is said to be. See dynamic stiffness; static stiffness.