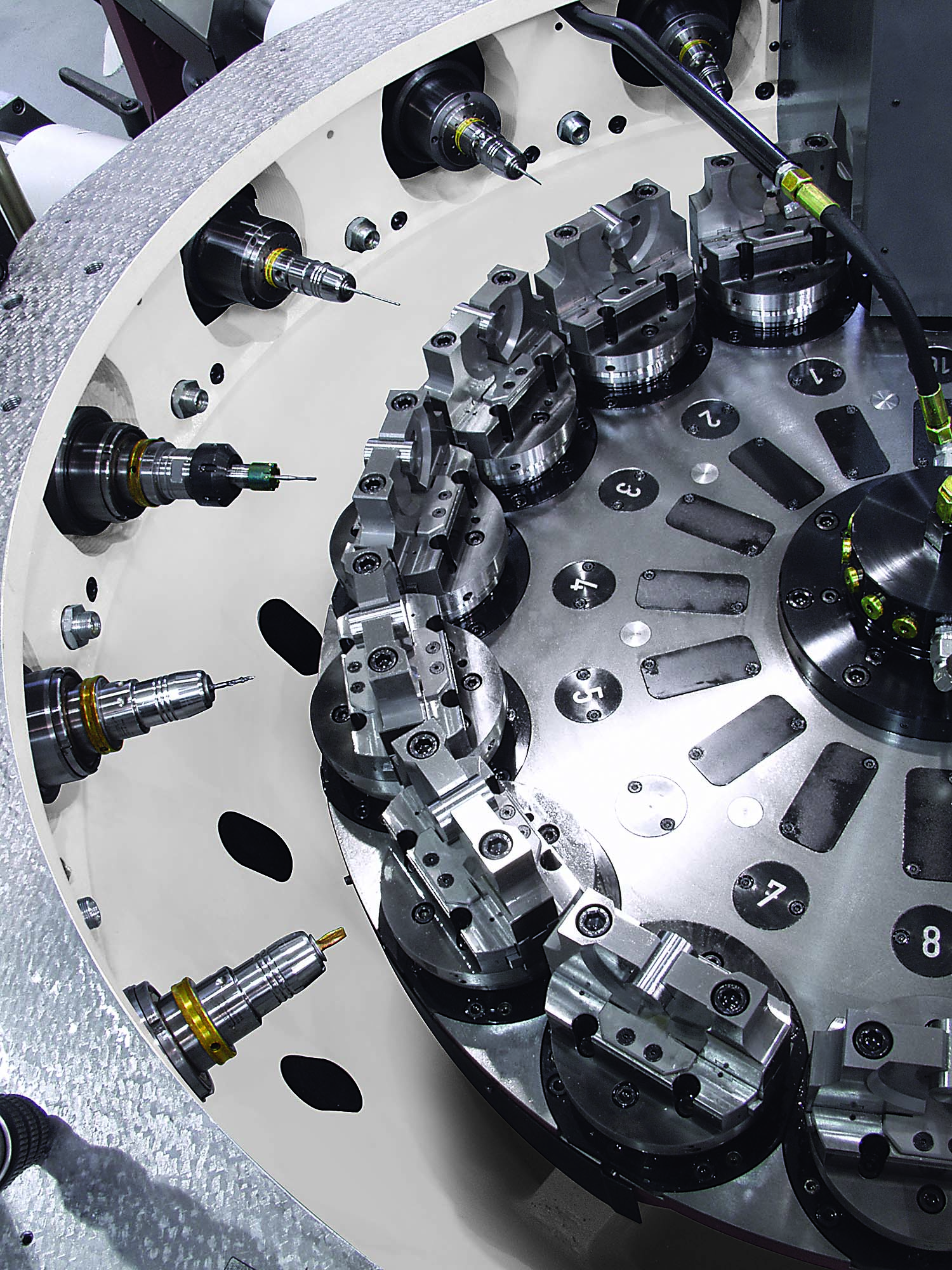

Some machine tools are modified so much and so frequently it becomes a common practice. That’s certainly the case with rotary transfer machines.

Kevin Shults, director of marketing at rotary transfer machine builder Hydromat Inc., St. Louis, said the company offers several standard machine platforms. Each model can be customized to machine a specific part or family of parts. These adjustments can be made quickly, and, afterwards, the machines are often used to produce millions of parts annually.

With the traditional rotary transfer concept of the past, once a machine was set up, it could run for years. If changeover were needed, retooling could take days or even weeks.

Rotary transfer machines are highly customizable and able to complete even complex parts in seconds. Image courtesy of Hydromat.

That paradigm started to change during the 1990s, when Hydromat and others began to equip machines with CNC slides. This change decreased the machines’ dependence on hydraulic or cam-operated slides and greatly increased their flexibility.

In 2004, Hydromat introduced an all-CNC machine with stand-alone, independent slides. According to Shults, the new machine completely changed the rotary transfer machine landscape. “The Epic RT eliminated the centralized electrical cabinet common on this equipment,” he said. “There was no longer a need to rewire everything when reconfiguring it for a new job, so setup became a matter of hours. It created an entirely new market.”

The market is about to change again. Hydromat will introduce its next “big thing” in rotary transfer technology, the Eclipse, at the company’s October 2017 open house. Shults said the machine will have an entirely new base and redesigned spindles. It will be nearly twice the size of existing machines and able to accept 65mm (2.56") bar stock. The Eclipse will be built at Hydromat’s St. Louis facility.

“We not only needed a bigger machine, but one that can perform more complex work,” Shults said. “Where one customer wants to make parts in 14 seconds and hold tolerances of a few microns, others want to machine more difficult material or make small quantities−maybe 30 pieces−and do a setup in a few minutes. It’s a daunting task, but that’s the nature of our business these days.”

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- family of parts

family of parts

Parts grouped by shape and size for efficient manufacturing.

- rotary transfer machine

rotary transfer machine

Type of CNC machine tool for high-volume, extended-length production runs of a family of parts. A workpiece is transferred from station to station in a rotary fashion and a tool or tools at each station performs one or more operations until the part is completed.