CNC machine tool owners with a healthy concern for their employees are advised to enclose their machines in protective structures.

These structures, known as enclosures, serve as barriers between shop personnel and materials like swarf and coolants traveling from a machine—sometimes at high speeds—during cutting operations.

While the main purpose of an enclosure is to keep people safe, it can perform another important function as well.

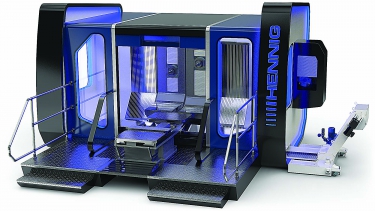

A machine enclosure protects operators from injury and machinery from damage. Image courtesy of Hennig.

“We like to say we’re in the business of protecting companies’ assets,” said Aaron McDevitt, president of Faztek LLC, a Fort Wayne, Ind., supplier of custom machine safety products. “That means protecting their employees, for sure, but also protecting machines.” For example, an enclosure can safeguard a machine from forklift impacts and harmful substances in the surrounding environment.

For many applications, metal is the preferred choice for enclosure panels. Hennig Inc., Machesney Park, Ill., makes most of its enclosure panels out of cold-rolled steel. The thickness of these panels varies from 14 to 7 gauge, depending on the machine’s spindle speed, according to Frank Chavez, engineering and business unit manager of Hennig’s fabrications division. (Spindle speed determines how fast a projectile exits a machine.)

Instead of cold-rolled steel, Hennig sometimes opts for stainless steel enclosure panels. With its smoother surface, stainless steel can be a little better at deflecting chips and coolant coming from the work zone, Chavez said. Another option for Hennig is aluminum, which can be used to lighten the loads of large enclosure panels.

When enclosure panels are made of metal, windows allow machine operators to see inside. According to Chavez, Hennig enclosures include “safety-level” windows made of materials such as laminated glass, which consists of a protective vinyl layer inside two glass layers.

Other enclosure options besides those with metal panels include wire mesh and plastic structures, both of which Faztek sells. “If the customer is trying to keep peoples’ fingers out of the machining area and keep large chunks of material from flying out, we can use a wire mesh,” McDevitt said. However, “if some type of coolant is being sprayed around and the customer needs to have good visibility into the machine, we will go with polycarbonate.”

Faztek uses 3⁄16"- or 1⁄2"- thick polycarbonate sheets to make its transparent plastic enclosures, depending on the impact resistance needed. “If your machine tool is throwing out 1"×1" boring chips at 400 mph, we would go with 1⁄2" polycarbonate sheet,” McDevitt said.

In some cases, only steel panels may be able to provide enough impact resistance to deflect large chunks of material flying from the machining area, McDevitt said. Steel is also a better choice for applications generating extreme heat that could melt plastic panels, he added.

Faztek designed this enclosure for a customer’s machine. Image courtesy of Faztek.

In addition to performing their traditional protective functions, CNC machine tool enclosures need to look good these days. That is because machine tool OEMs are using the aesthetic appeal of enclosures as a marketing tool to make machines more appealing to potential buyers, according to Chavez. Hennig sells enclosures to machine OEMs for new products, as well as retrofitting machines already in use with enclosures.

“Over the last 5 years, the industry has really moved in this direction to give customers something pleasing to the eye,” Chavez said. He cited examples such as the addition of radius corners, attractive color schemes and backlit laser cuts of the machine OEM’s name.

Though enclosures tend to improve machining operations, they do have downsides. For one, they add to setup times. In addition, they create a “speed bump” for operators, McDevitt noted, requiring operators to open and close the enclosure door to move parts in and out of the machine. Even though these actions take only seconds, he said, the seconds add up for operators who are trying to machine thousands of parts per shift.

“That’s why you have to educate people about the cost if somebody gets hurt and then OSHA or an internal safety team shuts that machine down for 2 weeks while they do an investigation,” McDevitt said. An enclosure “pays for itself over the long haul because it keeps you from getting into those situations.”

Contact Details

Contact Details

Related Glossary Terms

- boring

boring

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- swarf

swarf

Metal fines and grinding wheel particles generated during grinding.