When Nippon Bearing Co. Ltd. started developing its EXRAIL roller guide, it wanted to strengthen its overall line. The company has a long history of manufacturing linear ball bearings, said Tomohiko Kikuchi, assistant manager of R&D, but not as much experience making linear guides with rollers.

The research Kikuchi and his team conducted led them to focus on exceeding standards in rigidity, motion accuracy and damping capability. The team interviewed representatives from machine tool builders, asking them what improvements could be made to linear guides.

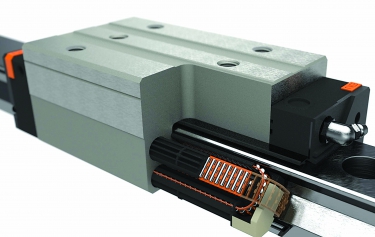

EXRAIL has 1.5 times the rigidity of a conventional roller guide, according to the company. Image courtesy of Nippon Bearing.

The solution centered on the use of needle rollers, which are long but also have reduced diameters. The smallest EXRAIL block, for example, has a diameter of 2mm (0.079") and a length of 8mm (0.315"). Fitting multiple needle rollers into the block disperses the load, which reduces elastic deformation. This reduction is key to enhanced rigidity. According to the company, the EXRAIL has 1.5 times the rigidity of a conventional roller guide.

Furthermore, dispersing the load reduces vibration, which increases accuracy. The company used laser measuring equipment to study the impact on vibration as the block moved along the EXRAIL guide and concluded that vibration was reduced by half.

Another focus was on damping capability. The use of multiple rollers improves frictional resistance, which increases vibration damping. The company found EXRAIL damping to be 1.5 times higher than what is generally found in the market.

The team wanted to incorporate as many rollers as possible into the recirculated raceway. A challenge was selecting the material for the roller’s retainer. It needed flexibility and strength.

The team tested stainless steel sheet metal with metallic foil but ultimately incorporated a resin film to strengthen the material.

The design of the EXRAIL also provides other benefits. For example, the contact of the lubricated resin material and the rollers extends the length of the required relubrication interval.

Summarizing these developments, Kikuchi concluded, “Parts with precision are always in need in machine tools. I believe that the EXRAIL will expand the possibilities for machine tools.”

For more information about Nippon Bearing Co. Ltd., visit exrail.jp/en or contact NB Corp. of America, Hanover Park, Ill., at (800) 521-2045.