Manufacturers have been steadily advancing automation for decades. These advances have resulted in robots that tend machines and even paint and weld, CNC machine tools that run unattended and integrated work cells that have replaced entire teams of technicians. More than ever, companies seek ways to improve efficiency through

automation.

Automotive manufacturers traditionally have been the primary drivers of automation in manufacturing. Tasks like painting and frame welding once required a person to commit to hundreds or thousands of hours of training before mastery. Supporting production called for hundreds of people to master these skills. Automation, such as robots, has been developed to perform these tasks so accurately and consistently that only a few people now are needed to monitor production during frame fabrication and painting.

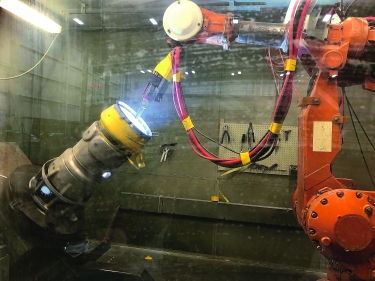

Mitsubishi Hitachi Power Systems Americas Inc. applies ceramic coatings to combustion parts using a plasma torch. This environment is too harsh and this work is too demanding for people, so robots are necessary. Image courtesy of C. Tate

Transfer lines found at high-volume machine shops like those that build engines can have several machines performing various machining operations where parts and tools move from machine to machine with no machinist present in a cell. There often is just one person who tends a cell by loading parts, changing cutting tools and monitoring machine tool condition. For the most advanced cells, a person is involved only occasionally, and they operate unattended much of the time.

Time to Mastery

Automated processes reduce the time needed to gain proficiency. Machining is a good example. Mastering the machining trade takes substantial mental aptitude and years of training and practice. Even early automation like turret lathes required many hours of training to master. But the CNC machines frequently found today at manufacturing facilities allow technicians with little experience to succeed with minimal training.

Automation also improves part quality. Human intervention is a significant cause of defects in machining processes. The high level of repeatability that can be achieved through automation mitigates the risks that arise when people interact with machines and processes.

Robots used for loading and unloading pallets or moving parts in dangerous areas greatly enhance worker safety. Earlier in my career, I worked for a Japanese automotive manufacturer that adhered to the Toyota Production System. At that time, the TPS philosophy discouraged the use of automation, but we exclusively used robots and other automation in the confined space of a heat treatment cell where parts were hot, wet and slippery. Manual operation of these heat treatment workstations was dangerous, so it was out of the question to expect people to work in them.

For many years, automating machine tools usually meant adding a bar feeder, pallet changer, large-volume toolchanger, robotic loader or combination of these. However, automation is changing. Machinists now can adjust a cutting tool with a smartphone. It is hard to imagine what will be available in the future with gains from the industrial internet of things, artificial intelligence and exponential increases in computing power.

It’s not difficult to understand why automation is desirable or why the demand for more advanced technology is increasing, but automation can come with drawbacks.

Diminution or elimination of human involvement — the primary purpose of automating — is not always desirable. Humans are very good at some activities that robots and automation are not. Humans can learn faster and adapt quicker and are capable of independent thought, which is usually a desired quality. It’s not ironic that AI and machine learning are focal points at research institutions.

Rigid Robots

Robots, along with other types of automation, are not flexible. Even the technologies capable of being moved throughout a plant must be configured for each job. Robots require specific tools called end effectors, which allow them to interact with the work. If you move a robot to a new job, you’ll likely need a different end effector, along with a new program. If you move a person to a new job, he or she may be effective immediately — no end effectors or programs are needed.

In addition, automation cannot adapt quickly to variation like a person can. A good example is at Boeing Co. where engineers had been developing robots to drill holes and install rivets that hold the skin of an aircraft in place. The company abandoned the project after six years of development and millions of dollars in investment because humans have the ability to react instantly to small anomalies and variations, but robots do not. A robot with the most advanced processors, optics and controls cannot adjust to variation like a human can.

As we continue to improve our technology and machines, we should not forget that automation is ineffective without skilled craftspeople. Even state-of-the-art CNC machines, robots and digital devices must be programmed by someone who knows how to perform the work. It is imperative that we begin to emphasize the need for skilled trades, along with cutting-edge technologies. Otherwise, technological advances will be diminished by a lack of experience.

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- toolchanger

toolchanger

Carriage or drum attached to a machining center that holds tools until needed; when a tool is needed, the toolchanger inserts the tool into the machine spindle. See automatic toolchanger.