When was the last time someone sat your team down and talked about safety? Where I work, we sit down once or twice a year for safety sessions. These sessions typically include both shop and office personnel, cover several topics and last about 45 minutes. Associates who are off-site or can’t attend can still participate remotely and take a short test to verify they understand the subject matter.

When was the last time someone sat your team down and talked about safety? Where I work, we sit down once or twice a year for safety sessions. These sessions typically include both shop and office personnel, cover several topics and last about 45 minutes. Associates who are off-site or can’t attend can still participate remotely and take a short test to verify they understand the subject matter.

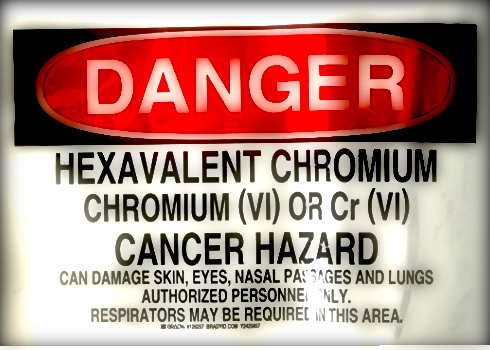

One of the subjects covered at the last session was hexavalent chromium, or chromium 6—also called hex chrome.

Hexavalent chromium is generated in various ways, such as when welding stainless steel and manufacturing glass and during the chrome-plating process. Although I worked in a suburban-Chicago chrome-plating shop for a brief time many years ago, I never really knew about hex chrome until the latest meeting conducted by my current employer. The chrome plater didn’t provide workers with goggles or respirators, which, in retrospect, was foolish because hex chrome enters the body by inhaling dust, mist or fume, or by contacting liquid that contains hex chrome.

The major health effects from hex-chrome exposure include lung cancer, nasal septum ulcers, bronchitis and asthma. Statistics indicate the cancer risk from hex-chrome exposure is much higher than exposure to asbestos or benzene—nasty stuff.

At the safety session, my company showed an image of a hole in the nasal septum caused by exposure to hex chrome at a chrome-plating shop. After the meeting, I just had to check my nose and, thankfully, didn’t find any ulcers.

The OSHA workplace standard is a personal exposure limit (PEL) of 5µg/m³ over an 8-hour period. The action level (AL) is 2.5µg/m³ over an 8-hour period. If the air-monitoring concentration is below the AL, no further monitoring is required. If the concentration is at or above the AL, monitoring should be done every 6 months. If the concentration is above the PEL, monitoring must be done every 3 months.

How do you control exposure to hex chrome? First, if you don’t belong in an area where you’ll be exposed to it, don’t go there. That area should be separated from the rest of the workplace and accessed only by authorized employees.

When in an exposure area, always wear a respirator and don’t eat, drink or smoke while there. When on break, wash your hands before eating, drinking or smoking.

Per OSHA requirements, an employer must provide personal protective equipment, such as goggles, gloves and coveralls, when skin or eye contact with hex chrome can occur. Don’t wear or take this equipment home. Also, don’t remove hex chrome by shaking clothing like a rug or using an air gun to blow it off, which only disperses it into the air. An employer must launder the clothing and, if needed, repair or replace it.

In addition, the work area must be cleaned using a vacuum with HEPA filters—or a similar high-efficiency-particulate-arrestance cleaning method—to minimize exposure. Dispose of any waste, scrap and debris that is contaminated with hex chrome in a sealed, impermeable container.

Whether a safety meeting is about trip hazards, lifting procedures or exposure to chemicals, pay attention. A company’s team members tasked with disseminating worker safety information don’t conduct these meetings just to hear themselves talk, they do it to protect you.