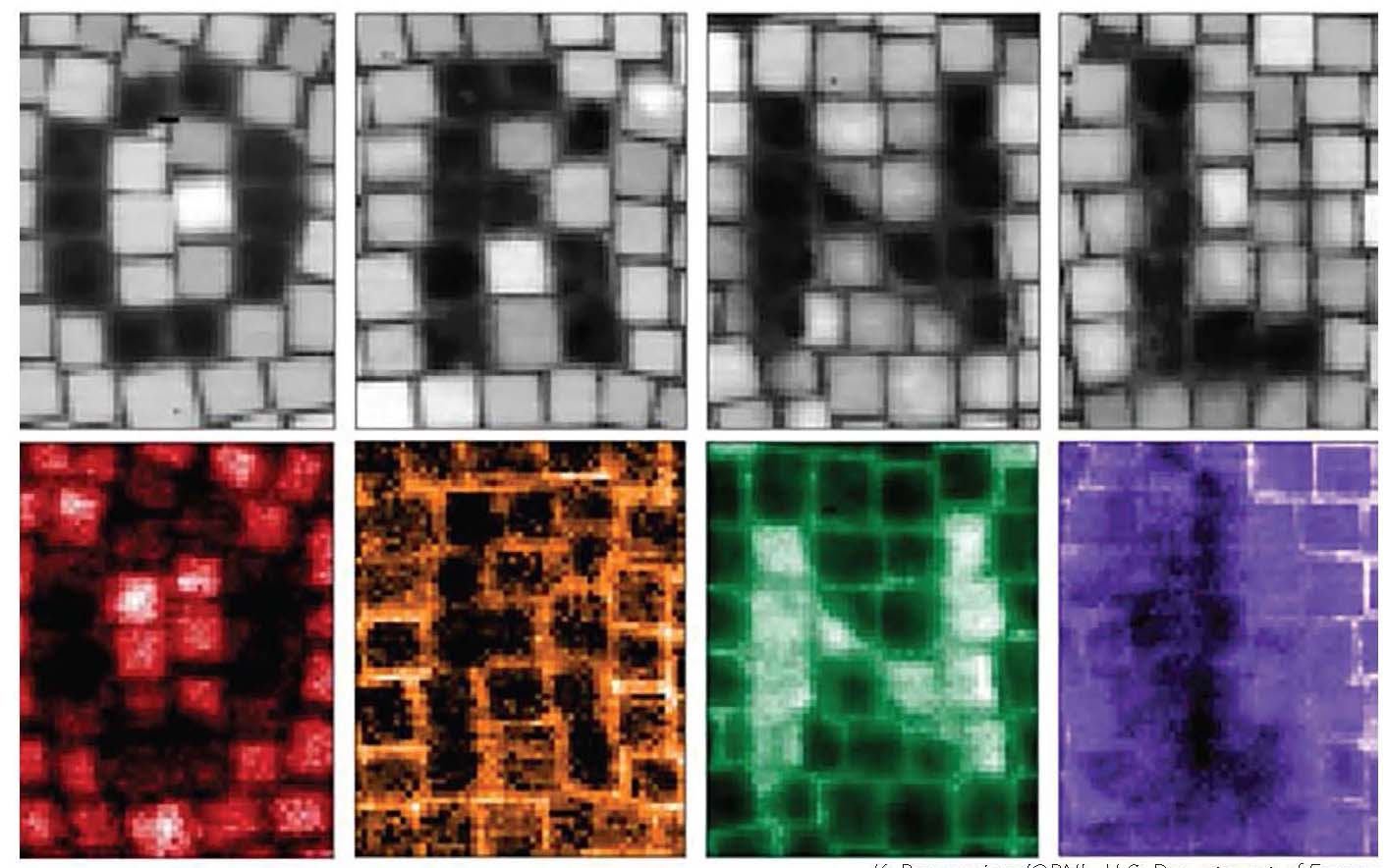

Drilling with the beam of an electron microscope, scientists at the U.S. Department of Energy’s Oak Ridge National Laboratory precisely machined tiny, electrically conductive cubes that can interact with light and organized them in patterned structures that confine and relay the electromagnetic signal of light. This demonstration is a step toward potentially faster computer chips and more perceptive sensors. The seeming wizardry of these structures comes from the ability of their surfaces to support collective waves of electrons, which are called plasmons, with the same frequency as light waves but with much tighter confinement. The light-guiding structures are measured in nanometers, or billionths of a meter — 100,000 times thinner than a human hair.

Plasmonic phenomena first were observed in metals, which are conductive because of their free electrons. The ORNL team used cubes made of a transparent semiconductor that behaves like a metal: indium oxide doped — that is, a small impurity is added — with tin and fluorine.

The study builds on prior work to sculpt 3D structures as small as a nanometer with an electron beam.

“The current paper proves that the plasmonic effect, as well as the structure, can be sculpted,” said ORNL’s Kevin Roccapriore, first author of the study. “At the end of the day, we’re interested in the electron wave: Where is it, and what is its energy? We’re controlling those two things.”

“We want to transition from using what exists in nature by chance to fabricating materials with the right responses,” said senior author Sergei Kalinin of ORNL. “We can take a system of cubes, shine light on it and channel energy into small volumes localized exactly where we want them to be.”

The project was a natural for Roccapriore, who conducted a lot of electron beam lithography in graduate school and even built a machine in his garage to make and mill 3D-printed structures. At ORNL, experimenting with the beam of an electron microscope, he adjusted its current to intentionally shift from imaging to modification mode. He found he could remove bits of cubes or entire cubes from an array to make patterned objects at will. He also discovered that, just as the addition of chemical elements enables tuning of cube energies, so too does selective removal of chemical elements. Such atomic precision is possible with scanning transmission electron microscopy.

The scientists plan to create a library of relationships among materials, structures and plasmonic properties. That new knowledge will provide the foundational understanding needed to eventually mass-produce structures that can direct the flow of light in plasmonic nanocircuits.

“The idea is to understand the relationships using machine learning and then automate the process,” Roccapriore said.

— Oak Ridge National Laboratory

For more information about the plasmonic project, view a video presentation at cteplus.delivr.com/2vafb

Related Glossary Terms

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- titanium nitride ( TiN)

titanium nitride ( TiN)

Added to titanium-carbide tooling to permit machining of hard metals at high speeds. Also used as a tool coating. See coated tools.