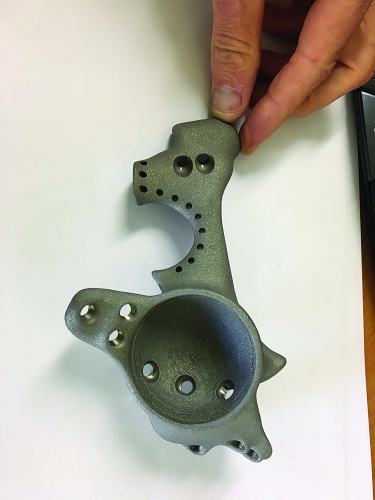

Are you being asked to quote secondary machining operations on a handful of 3D-printed metal parts? If so, how do you cut these parts?

A quick Google search returns images of some cool-looking components, but what’s with all the curvy geometries and gnarly surface finishes that, at first glance, appear rougher than corn cobs? 3D-printed parts must be tough to machine, right?

Actually, there’s little to worry about, at least from a machinability perspective.

According to industry experts—such as the additive-manufacturing consulting firm Wohlers Associates, Fort Collins, Colo., and simulation and product development experts Phoenix Analysis and Design Technologies (PADT)—3D-printed metal from laser-based powder-bed fusion systems cuts no differently than a billet of 17-4 PH stainless steel, titanium, Inconel or one of the many other alloys available today.

This titanium hip implant looks like tough stuff, but the most-difficult thing about machining parts like these is fixturing them. Image courtesy of McClay Tooling.

“In general, for parts printed using powder-bed laser melting processes, we recommend the standard speeds, feed rates and cutting tools found in the Machinery’s Handbook,” said Rey Chu, principal of PADT, Tempe, Ariz.

But not so fast. Mark Fisher, workshop manager at Christchurch, New Zealand, machine shop McClay Tooling Ltd., agreed that the 3D-printed titanium hip implants the company machines are virtually indistinguishable from titanium bar stock, except for their “slightly harder skin.” For these parts, McClay designed proprietary cutters that it operates at feeds and speeds Fisher is unable to discuss. He is, however, willing to point out the difficulties faced in fixturing these parts due to their complex, organic shapes, a factor that also presents challenges during 5-axis machining operations.

“Other than that, the material has a nice, fine-grain structure that isn’t too difficult to cut,” Fisher said.

Eric Utley, applications engineer at Minneapolis-based Proto Labs’ Morrisville, N.C., location, said 3D-printed metals are “like machining a sand-casted part” and agreed that fixturing is probably the biggest struggle. “You have to wrap your head around how to hold these parts, where you’re going to touch off and make sure you’re machining what actually needs machining. That said, one of the beauties of 3D printing is that it’s usually easy to design in part-locating surfaces, provided you think about it in advance.”

Another thing Utley mentioned is part stress. The 3D printing process generates tremendous temperature differentials as the powdered metal melts and rapidly cools, layer by layer, until the workpiece is complete. That’s why Proto Labs heat-treats nearly all 3D-printed metal parts. Without this secondary stress-relief process, it’s possible the part would curl up like a potato chip during machining.

“The sintering process creates some pretty extreme internal stresses,” Utley said. “Even without machining, it’s important to remove them if you’re going to produce a stable part.”

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- machinability

machinability

The relative ease of machining metals and alloys.

- sintering

sintering

Bonding of adjacent surfaces in a mass of particles by molecular or atomic attraction on heating at high temperatures below the melting temperature of any constituent in the material. Sintering strengthens and increases the density of a powder mass and recrystallizes powder metals.