Machine maintenance programs boost bottom line

Machine maintenance programs boost bottom line

A little spending now can keep machine shops up and earning.

Looking for ways to save thousands or even millions of dollars?

That question might sound like a scam, maybe the subject line of spam. But it isn't a ruse. While not every company will see a seven-figure dividend, any part manufacturer can save money by reducing machine tool downtime, especially the unplanned variety, through the use of predictive or preventive maintenance programs offered by equipment suppliers and third-party firms.

Few breakdowns happen without warning. If warnings are noted through regularly scheduled maintenance procedures or real-time data analysis and action, costly breakdowns can be mitigated.

Spending a little today on machine maintenance often offsets future repair costs, said Jack Lugas, field service engineer for Absolute Machine Tools Inc., Lorain, Ohio. According to research company ARC Advisory Group Inc., unplanned breakdowns typically cost 10 times more than planned downtime. A study by Aberdeen found that unplanned downtime can cost a company as much as $260,000 an hour. Overall, unplanned downtime annually costs manufacturers $50 billion, according to a Wall Street Journal article, and equipment failure is the cause of 42% of this unplanned downtime.

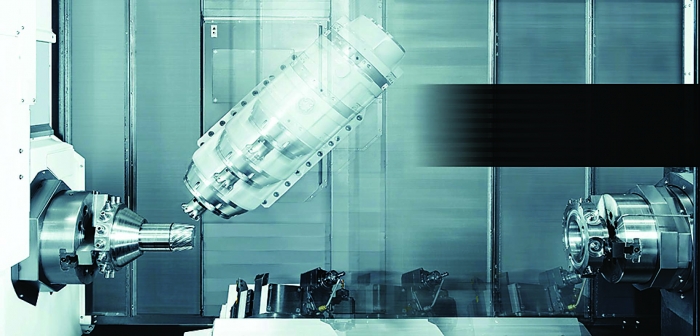

Simple procedures can prevent spindle failures. Image courtesy of OPS-Ingersoll Funkenerosion

In addition to not having access to out-of-order machines, manufacturers may not get as much from machines when they work. Some companies purchase equipment to increase capacity when they don't need to, said Graham Immerman, executive director of

marketing for Northampton, Massachusetts-based MachineMetrics Inc., which provides out-of-the-box industrial internet of things connectivity. He said the average machine utilization rate for the machines that his company deals with is 27%.

"So the question becomes, when you are justifying capital equipment spending, are you getting everything you can out of the machinery that you currently have?" he said. "The answer almost certainly is no."

Maintenance costs can be hard to justify, especially if nothing goes wrong. When chips are flying and spindles are turning, money is made, so the incentive to curtail production is low. While some companies religiously maintain machines, others do not, Lugas said.

"Mostly because they are too busy," he said. "Mostly because maintenance is a cost item, not a moneymaking endeavor."

Predict or Prevent

Predictive and preventive maintenance are two programs that help manufacturers reduce the frequency and duration of machine downtime, though in different ways.

Changing filters is a minor task that can be critical to optimal machine operation. Image courtesy of Absolute Machine Tools

Predictive analytics allows users to analyze real-time data for just-in-time maintenance by comparing information with known scenarios. For instance, what does it mean when cutting speed operates at a certain rpm during a particular machining operation? How does that situation compare with known failure modes? Preventive maintenance programs are based on predetermined factors, typically time and usage.

With predictive maintenance, real-time machine data is compared, and any necessary alerts are sent so decisions can be made. Operators can log in from anywhere with internet connectivity. Machines eventually might feature artificial intelligence and machine learning algorithms that automatically can order parts or schedule maintenance.

The intriguing possibility of self-maintaining equipment is partly why predictive maintenance is one of the hottest offerings in manufacturing. Equipment suppliers are integrating predictive maintenance into their offerings. Third-party companies, such as MachineMetrics, are aiding the data-driven machine maintenance process from the OEM to the machine and tool supplier. According to a November report from ReportLinker, the predictive maintenance market is expected to reach $12.7 billion by 2025.

Using big data and machine learning, a large quantity of data is systemically analyzed and incorporated into processes that can predict when equipment could fail. By monitoring machine performance during normal operation to set baselines, previously captured machine performance can be compared with real-time data to determine if there is a problem or if one is developing.

Mazak Corp., for instance, has expanded its data-driven decision-making capabilities. Joe Sanders, pro-cess development coordinator for the Florence, Kentucky-based machine tool builder, said monitoring spindle health can reveal impending failures based on specific types of performance measurement data. For example, analysis can look for vibration signatures that signal bearing failures, but unless the monitoring system can distinguish between signatures that spell damage and those that don't, the system can report false positives.

"An AI-based monitoring solution can use a baseline assessment of a spindle to determine when performance is heading toward a critically impaired state," he said. "This can reduce downtime and the production of out-of-tolerance parts."

Parameters, such as critical speeds and changing spindle position, also can be tracked continuously. Vibration analysis gives insight about wear on bearings and shafts by comparing previous vibration patterns.

Temperature is an important parameter too. Rafael Linan, field service manager for United Grinding North America Inc., Miamisburg, Ohio, said thermistors can track the temperature of key components.

Vibration analysis can determine spindle health. image courtesy of Mazak

"Electrical components in cabinets should remain under 55° C (131° F)," he said. "If a $10 fan isn't working, a capacitor can overheat, and the controller can burn out. And the CNC costs $15,000 to replace."

Knowing the critical parameter or combination of parameters is paramount to utilizing predictive maintenance. New ways to continuously improve production might be developed if the right combination of information is conceived.

"The importance of proper maintenance cycles has always existed and is an area of continuous improvement for most companies," said Alan Hallmann, North American sales manager for MC Machinery Systems Inc., Elk Grove Village, Illinois. "With an ever-growing amount of automation being used in industry to offset labor costs or labor availability, these machines can run more efficiently and around the clock."

This requires more maintenance intervals.

With "the implementation of machine monitoring and software packages to organize the data for efficiency — i.e., Industry 4.0 or smart manufacturing — we can now obtain a more predictive approach to when maintenance is scheduled," Hallmann said. "This increases the need for maintenance and further showcases its importance."

At United Grinding North America, Linan said, "We are working on something that we call digital solutions in which we compare a machine's hours to the amount of time each component should last, and then we have a system that tracks the productivity and life expectancy. Based on parameters, we are able to advise the customer to repair an item or look at certain components."

Implementation Challenges

Many equipment types can capture data, and nearly all manufacturing facilities feature a mix of machinery — much of which "speaks" its own language. Other equipment utilizes communication protocols like MTConnect or Open Platform Communications.

"There are hundreds of different makes and models (of equipment), a range of legacies new to old, and they all speak different languages with different protocols," Immerman said. "And the data on the different machines especially is written in different languages. So even if data is collected, how would you compare the load on one machine with the load on another machine? The answer is that data needs to be transformed. MachineMetrics can collect and automatically transform all of these different protocols into a standard language of our own, and that immediately makes data (from) all different machines comparable, actionable. You can start leveraging it to make decisions."

He said most manufacturers lack visibility about the problems on shop floors. To be visible, each process must be known and considered.

To effectively utilize predictive maintenance, a company needs to predict with certainty the appropriate data and combinations of data for a machine. Implementation starts with a solid understanding of process variables and machines and a strong dataset. However, that might be easier said than done.

Boots on the Ground

Compared with the challenges of predictive maintenance, preventive maintenance — with its regularly scheduled, in-house visits — may be a better solution. It is definitely easier to implement and less costly. Maintenance schedules can be determined based on periods of time or triggered by reaching known usage factors.

Some maintenance work necessitates tearing down and rebuilding, and some requires regimented elbow grease.

Hallmann, for instance, said, "Any piece of mechanical equipment benefits from regular cleaning and maintenance. If these items were not cleaned and maintained on a regular basis, the life cycle of the items would be shortened. In many cases, safety would be compromised by the users."

MC Machinery Systems, which distributes a variety of equipment, including from Germany-based machine tool builder OPS-Ingersoll Funkenerosion GmbH, also offers options to service myriad machines, such as OPS-Ingersoll Funkenerosion's sinker EDMs and high-speed machining centers.

When a maintenance team always can view the latest conditions of machines, unplanned downtime is reduced. Image courtesy of United Grinding North America

"In a general shop environment," Hallmann said, "many components are exposed to contamination from the shop air, nearby machinery or metal chips generated by the mill-ing machine."

Cleaning, he said, is important for the following areas:

- The fans and air intakes on the controller and generator cabinets, ensuring that expensive electronics do not overheat due to fan failure or airflow restrictions.

- Linear ways and ballscrews, ensuring that damage does not occur due to debris.

- Way covers, ensuring proper operation of the covers to protect expensive high-accuracy guides and ballscrews.

- Work tank areas because if excessive dielectric sludge exists there, it can affect the overall quality of fluid supplied to cutting zones. In addition, abundant sludge under a work table may collide with the bottom of the table.

Linan said United Grinding North America is expanding service operations for digital solutions and in-person maintenance calls. The company already offers remote monitoring solutions.

Customers utilizing in-house visits can gain broader views of production environments. Lugas said when he goes to a facility, he observes everything from foundations for machines to incoming power and water. Absolute Machine Tools offers three levels of preventive maintenance programs: bronze, silver and gold.

"Don't cut corners," he said. "Is the machine on the right foundation? Are there variations in the power that goes into the machine or moisture in the air? Do you have a high-speed spindle that uses an air-oil mixture to keep bearings cool at those high rpms? If not, it could cause some type of failure to the spindle."

Daily CNC Machine Maintenance

These are the "apples a day" that keep CNC machine tools out of the machine emergency room. They sound simple because they are. Conducting a few minor checks at the end of each day or shift can help catch a problem before it snowballs into a major breakdown.

Check fluids. CNC machines require adequate fluid levels, such as lube and hydraulic fluid. Working daily with machines gives a good baseline for how quickly fluids need to be replenished. When machines start using fluid at a higher rate, have them checked. Excessive fluid use can be a sign of problems.

Give grease. It is the smooth operator that keeps all working parts moving and grooving. Not all machine shops check grease points each day, but shops should look at all moving parts for dry spots. A quick shot of grease goes a long way toward reducing unwanted wear.

Renew with a rag. Wipe down all surfaces to show a little shine by removing shop grime. Daily wiping of a machine also keeps small metal shavings from building up in damage-prone areas, such as way cover seals.

— Absolute Machine Tools

Machine Spring Cleaning

When performing a thorough spring cleaning of milling machines:

1. Remove chips from under way covers and the ballscrew area. Conduct a full-enclosure cleaning.

2. Check that all lubricants are at normal levels and functioning properly.

3. If necessary, make fine adjustments to an toolchanger/" data-glossary-id="142091" data-glossary-teaser="Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restor…" title="Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restor…" aria-label="Glossary: automatic toolchanger">automatic toolchanger so it continues to change tools without hang-ups or jams.

4. Inspect a spindle and spindle drivetrain to ensure that there are no contaminants that would affect the life of the spindle.

5. Check spindle belts for tension, oil, chips and wear to avoid unnecessary or untimely downtime and prevent compromising a part during cutting operations.

6. Perform a ball bar test to check the circularity and alignment of machine planes.

When performing a thorough spring cleaning of lathes:

1. Indicate the turret, tailstock and headstock alignment to ensure optimal accuracies and tool life.

2. Check that all lubricants are at normal levels and functioning properly.

3. If necessary, make fine adjustments to a turret to avoid issues with hang-ups, jams and indexing.

4. Check a hydraulic system for dirt and contamination.

5. Check an actuator for chip buildup.

6. Check spindle belts for tension, wear and overall condition to avoid unnecessary or untimely downtime and prevent compromising a part during cutting operations.

7. Perform a ball bar test to check the circularity and alignment of XZ planes.

For both types of machines, it is highly recommended to often check or change filters to ensure overall integrity of systems.

— Absolute Machine Tools

Glossary terms in this article