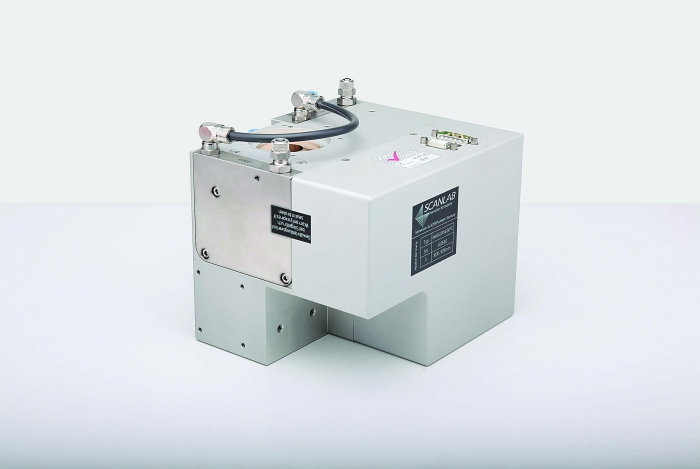

The welDYNA laser scan head from SCANLAB America Inc. uses beam oscillation to improve both joining and cutting applications.

Designed for multiple-kilowatt lasers of high beam quality, the scan head features a digital servocontrol and an integrated sensor system for real-time monitoring.

The company reports that the device is a solution to the challenge of substance-to-substance joining of unlike materials, such as aluminum and copper. Mechanical fasteners can negatively impact the electrical conductivity, heat transfer and mechanical strength of the joined materials. Meanwhile, effectively laser-welding together materials with different properties has been elusive, said Dale Sabo, vice president of sales and marketing at SCANLAB America.

The welDYNA laser scan head uses beam oscillation to improve welding and cutting. Image courtesy of SCANLAB America.

With traditional laser welding, the beam moves in a straight line along the seam where the two pieces to be welded meet. According to Sabo, as the beam moves, heat builds up in front of it in waves that cause irregular spikes in temperature. These spikes are difficult to control or compensate for—particularly when trying to join materials that respond differently to these spikes.

“Heat waves build up in front of the beam like water in front of the bow of a fast-moving boat,” Sabo said.

The welDYNA scan head smooths those rough waters through beam oscillation. As the laser beam moves up the line where the pieces to be joined meet, it also moves in high-frequency “wobble patterns,” such as from side to side or in a figure-eight pattern. This oscillation prevents the “bow-wave” of heat buildup. The overlapping laser beam motions relative to the seam geometry promote tear-resistant welds of diverse materials, even for unlike materials with poor weldability.

The same technology also improves laser cutting, according to Sabo. Beam oscillation allows faster cutting speeds and improves cutting quality, he said. “The ‘wobble motion’ frequencies of several kilohertz and the availability of freely definable scan patterns” reportedly deliver process parameters superior to those of other laser methods.

For more information about SCANLAB America Inc., St. Charles, Ill., visit www.scanlab-america.com or call (630) 797-2044.

Related Glossary Terms

- servocontrol

servocontrol

Refers to control of motion. Applied to the industrial robot, it describes automatic feedback, or “closed-loop,” operation in which sensing devices monitor movement and report any deviation between commands as issued and movement as monitored. Deviations trigger corrective action. Robots without servocontrol may be “open-loop” but most often are controlled by preset mechanical or electric stop-switches. Because they are not self-correcting, they have limited capabilities.