The aerospace industry is grinding more hardened ferrous metals and nickel-base superalloys and the automotive industry is grinding more difficult-to-machine drivetrain components. As a result, Element Six Ltd. introduced the ABN900 CBN superabrasive for electroplated grinding wheels to tackle those challenges, according to Ned Vaughan, the superabrasive material manufacturer’s product manager for precision grinding. “There are a multitude of other applications, especially where you’re looking to generate a form on a steel component,” he said, “but the predominant applications where we see benefits are in aerospace and automotive.”

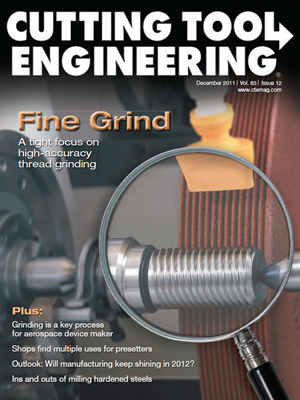

Courtesy of Element Six

A scanning electron microscope image shows Element Six’s ABN900 80/100 U.S. mesh grit size.

In addition to boosting productivity, Vaughan noted that a wheel made with ABN900 particles, which have a consistent blocky shape, exerts lower grinding forces than a wheel using previous grades to allow cooler cutting and minimize thermal damage to the component.

The biggest distinction between the new grade and others is extended tool life, according to Vaughan. In a test at the company’s laboratories against two other Element Six products (ABN300 and ABN800) and a leading competitor’s product for electroplated applications, the company reported that ABN900 outperformed all of them. That included a 55 percent improvement in tool life vs. the competitor’s CBN when grinding GGG70 SGI, a cast iron often used in auto parts, with a grit size of 120/140 U.S. mesh. ABN900 is available from 30/35 to 170/200 U.S. mesh and is suitable for roughing and finishing.

One property that helps extend wheel life is the material’s high strength. The new grade’s CBN grits are stronger than previous grades at room and elevated temperatures, noted Siobhan Duffy, business manager for advanced materials at Element Six. “We tested ABN900 at 1,100° C in an inert atmosphere and it has higher thermal stability strength in comparison to our other grades,” she said.

For more information about Element Six Ltd., Shannon, Ireland, call +353-614-60146 or visit www.e6.com.

Related Glossary Terms

- cubic boron nitride ( CBN)

cubic boron nitride ( CBN)

Crystal manufactured from boron nitride under high pressure and temperature. Used to cut hard-to-machine ferrous and nickel-base materials up to 70 HRC. Second hardest material after diamond. See superabrasive tools.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- grit size

grit size

Specified size of the abrasive particles in grinding wheels and other abrasive tools. Determines metal-removal capability and quality of finish.

- superalloys

superalloys

Tough, difficult-to-machine alloys; includes Hastelloy, Inconel and Monel. Many are nickel-base metals.