Using a novel polymerization process, chemical engineers at Massachusetts Institute of Technology have created a material that is stronger than steel and as light as plastic and can be manufactured easily in large quantities.

The new material is a two-dimensional polymer that self-assembles into sheets, unlike all other polymers, which form one-dimensional, spaghettilike chains. Until now, scientists had believed that it was impossible to induce polymers to form 2D sheets.

Such a material could be used as a lightweight, durable coating or as a building material, said Michael Strano, Carbon P. Dubbs professor of chemical engineering at MIT and senior author of the study.

“We don’t usually think of plastics as being something that you could use to support a building, but with this material you can enable new things,” he said. “It has very unusual properties, and we’re very excited about that.”

The researchers have filed for two patents on the process used to generate the material. MIT postdoc Yuwen Zeng is lead author of the study.

Polymers, which include all plastics, consist of chains of building blocks called monomers. These chains grow by adding molecules onto their ends. Once formed, polymers can be shaped into three-dimensional objects using injection molding.

Polymer scientists long have hypothesized that if polymers could be induced to grow into a two-dimensional sheet, they should form extremely strong, lightweight materials. However, many decades of work in this field led to the conclusion that it was impossible to create such sheets. One reason for this was that if just one monomer rotates up or down, out of the plane of a growing sheet, the material will begin expanding in three dimensions, and the sheetlike structure will be lost.

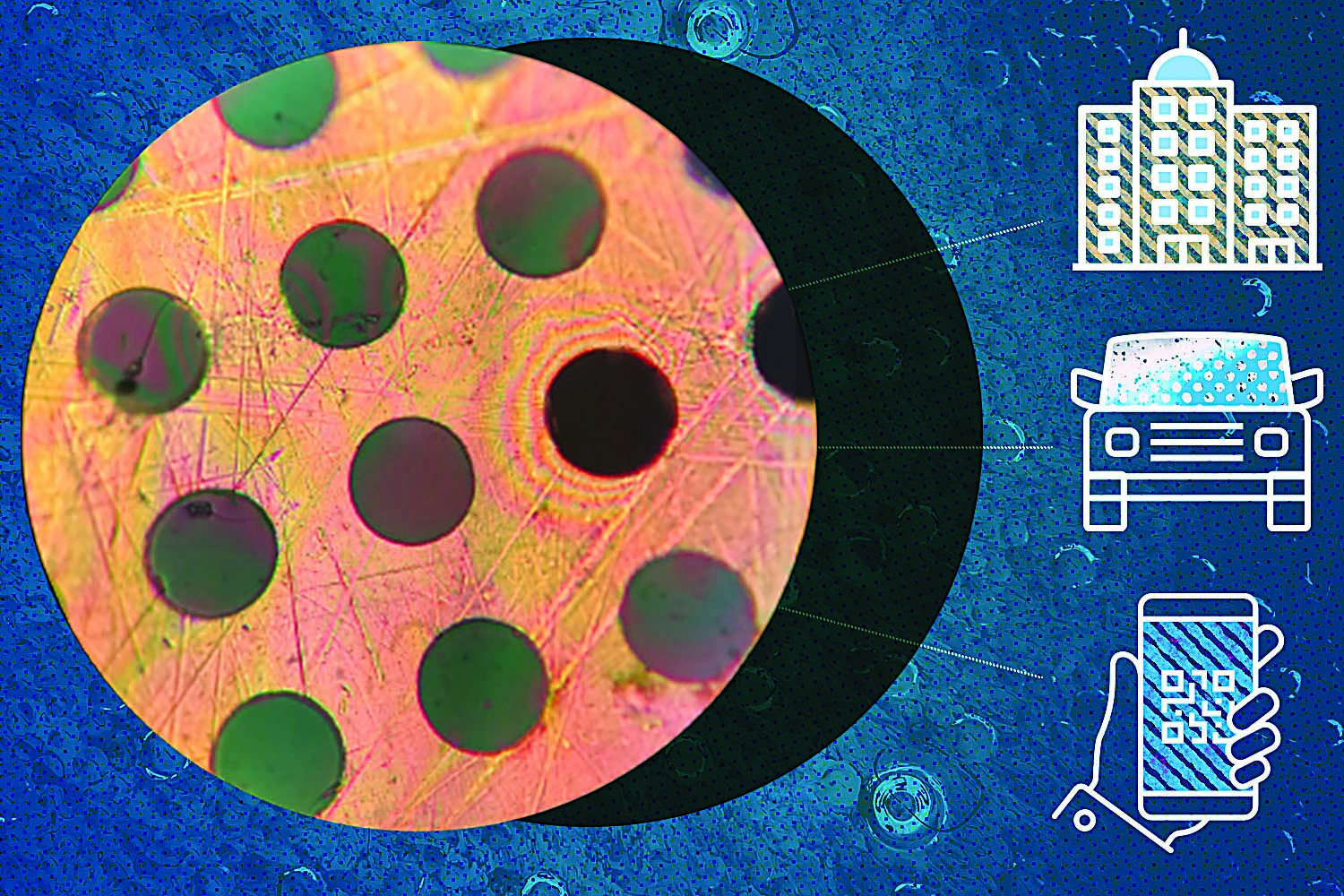

However, in the new study Strano and his colleagues came up with a polymerization process that allows them to generate a two-dimensional sheet called a polyaramide. For monomer building blocks, they use a compound called melamine, which contains a ring of carbon and nitrogen atoms. Under the right conditions, these monomers can grow in two dimensions, forming disks. These disks stack on top of each other, held together by hydrogen bonds between the layers, which make the structure very stable and strong.

“Instead of making a spaghettilike molecule, we can make a sheetlike molecular plane where we get molecules to hook themselves together in two dimensions,” he said. “This mechanism happens spontaneously in solution, and after we synthesize the material, we can easily spin-coat thin films that are extraordinarily strong.”

Because the material self-assembles in solution, it can be made in large quantities simply by increasing the quantity of the starting materials. The researchers showed they could coat surfaces with films of the material, which they call 2DPA-1.

“With this advance,” Strano said, “we have planar molecules that are going to be much easier to fashion into a very strong but extremely thin material.”

He and his students are studying in more detail how this particular polymer is able to form 2D sheets, and they are experimenting with changing its molecular makeup to create other types of novel materials.

— Anne Trafton, Massachusetts Institute of Technology