Many machinists have learned to dread tapping. The story goes something like this. They press cycle start and then step back because the machine is in control. If the tap should hit bottom, too bad; the cycle must be completed—no feed-hold is allowed here. If the wrong feed rate was programmed, tough luck; the feed rate override is disabled. What else is there to do but cringe as the tap enters the hole?

That’s one of the reasons tapping causes anxiety among CNC machine operators. That anxiety leads operators to take many precautions to assure the tap will complete its job of cutting an internal thread.

Other factors can fuel tapping anxiety. Feed rates are typically much higher than for most other cutting tools. With each revolution of the tap, the tool needs to advance one thread pitch. As an example, a 5⁄16-18 tap feeds at 1 divided by 18, or 0.055 ipr. The 0.257-dia. drill that created the hole might feed closer to 0.005 ipr.

It is quite common to tap at slower speeds to “feel” more in control. Slowing the spindle speed is the only way to effectively slow the feed into the hole. A 5⁄16-18 tap cutting at a spindle speed of 900 rpm would feed at 50 ipm, but at 720 rpm the feed would be only 40 ipm.

Understanding Tap Geometry

However, while tapping can be tricky, it is not beyond understanding. Tapping problems can be simplified and reduced by understanding tool geometry and what taps are best suited for a given application.

For example, lowering the chip load can eliminate premature wear on a tap. Defined as the load induced on any one cutting edge, chip load is typically controlled by altering the feed rate. As mentioned earlier, this is not possible when tapping but the chip load can be altered through tap selection.

Courtesy of Guhring

Tap with spiral point is shown with a steel part.

One approach might be to use taps with more flutes. With every flute added to the tap, a cutting face is added. With more cutting faces, the load on each tooth is reduced. For example, a 4-flute tap would have half the chip load per tooth of a 2-flute tap. This jives with standard metalcutting advice, which is to always use a maximum number of flutes. However, for tapping this advice would probably be wrong.

“More flutes means there is less space for chips as they are cut,” said David Miskinis, senior application specialist, holemaking for Kennametal Inc., Latrobe, Pa. “More flutes on the same circumference means smaller flutes, both in width and depth. With smaller space comes the risk of packing chips, which can lead to broken taps.”

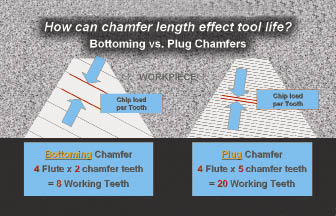

So, while adding flutes may not be an option, choosing a different chamfer length might be.

“Basically, a longer chamfer length means longer tool life,” said Dr. Peter Haenle, president of Guhring Inc., Brookfield, Wis. “The load during the cutting process is distributed over a longer cutting edge with a lower chip load.”

There are three common lengths of tap chamfers: taper at 7-10 threads, plug at three to five threads and bottoming with one to two threads. To provide more options, tap manufacturers have added a few more forms, including a form consisting of a two- to three-thread length, sometimes called semibottoming.

Adding length to the chamfer distributes the chip load over a longer cutting face. Effectively, more teeth are cutting the thread, similar to a single-point threading tool taking multiple passes.

“Chamfer lengths have a huge impact on tap life because they affect chip load,” Miskinis explained. “When comparing chamfer lengths of four threads or fewer, the tool life will double for every half thread added to the length.”

Clearly, increasing chamfer length in taps is desirable. Shorter chamfer lengths, such as in bottoming taps, wear faster and should be avoided, if possible. Unfortunately, there may not always be a choice.

“Taps with smaller chamfer lengths are usually used to keep the difference between hole depth and thread length to a minimum,” Haenle said. “Very often, the design of the part forces the use of taps with short chamfer lengths.”

Courtesy of Kennametal

Another way to tap more effectively is to manage chip thickness. For example, it is possible to thin the chip too much when tapping. Stringy chips can result from using taper chamfers and the tap may create a bird’s nest of chips, preventing lubricant from reaching the tool and chips from properly evacuating. As in other types of machining operations, increasing chip load can help break the chips.

Tap breakage is another issue that creates anxiety among machinists. The saying goes that it’s not the fall that kills you, it’s the sudden stop. But in tapping, it’s not the sudden reversal that causes taps to break, it’s the chips clogging the tool flutes. In some cases, this means chips are packed so tightly so that newly formed chips simply have no place to go, and the tap breaks from the stress.

Tackling Flute Clogging

Even if chips don’t pack so tightly that the tap breaks, flute clogging keeps lubricant away from the tool/workpiece interface and the friction of the chips on the tap creates excessive heat. Chip flow is a critical part of successful tapping. Which direction the chips should move is a factor of the type of hole to be tapped: through or blind. A spiral-flute tap lifts chips out of a blind-hole. The helical angle directs chips out of the hole.

The spiral flute can be referred to as slow, with 15° to 30° helical angles, or fast, with 40° to 60° angles. Faster spirals have a freer-cutting geometry, while slower spirals have a stronger cutting edge. Typically, fast spirals are for softer workpiece materials or materials that produce stringy chips, while slow spirals are for short-chipping, harder materials.

A spiral-point, or gun, tap pushes the chips ahead of the tap when tapping a through-hole. The spiral point itself is actually a left-handed spiral, ground only at the point of the tap, which creates a downward flow of chips. Otherwise, a spiral-point tap looks like a straight-flute hand tap.

Because the flutes of spiral point taps are not actually needed for chip evacuation and are instead applied to allow lubricant in, they can be shallow. Thus, they permit a larger core and a stronger tap. This also means that spiral-point taps can benefit from additional flutes without the problem of chip packing.

Selecting a Tap

Because tapping is a relatively complex operation, and because there are so many taps to choose from, selecting a tap can seem a daunting task. The main reason there are so many taps is because there are so many work materials. Tap manufacturers tailor tap design to the work material primarily through rake and relief.

The cutting face is that portion of the tap flute located between the major and minor diameter of the thread that cuts, or shears, the workpiece. The rake is the angle of the cutting face compared to a line from the center of the tap to the cutting face at the major diameter.

Courtesy of OSG

The image at left is of a tap with negative rake resulting in a strong cutting face for tough materials. Note that the cutting face at the root of the thread leads the remainder of the cutting edge. The center image shows a neutral rake. Here a line drawn along the cutting face continues to the center of the tool. The image at right is of a tap with a positive rake for free cutting of softer materials. Note how the cutting face leads from the major diameter, the reverse of the negative rake.

A rake is positive if the crest of the cutting edge is angularly ahead of the remaining part of the face. While not as strong as negative rakes, positive rake angles have excellent shearing capabilities.

A negative rake has the crest of the cutting face behind the rest of the cutting face. While this is a stronger geometry than a positive rake, it also requires more torque and creates more heat in the cut.

The shape of the cutting face is also a factor in tap performance. Cutting faces can also be straight or curved. The straight surfaces are normally referred to as rakes or straight rakes and the curved surfaces as hooks.

“Applying a rake, or straight face, will improve strength while a hook, or curved shape, will result in greater shearing ability,” said Andrew Strauchen, engineering and marketing manager, OSG Tap & Die Inc., Glendale Heights, Ill. “For performance taps, cutting [rake] angles are determined by the intended work material; higher angles are used for softer materials and low angles for harder materials.”

Tap relief is defined as the removal of metal from behind the cutting edge. A higher relief indicates more clearance between the tool and the workpiece. There are three main types of relief: concentric, eccentric and con-eccentric.

Concentric relief indicates that the lands of the tap, the part of the tap that remains after the flutes are cut, are concentric with the threads. This actually provides no relief and thus the surface of the tap rubs on the surface of the threads being cut.

Hand taps are made with concentric relief. Because they are used by hand, cutting speeds are low and friction and heat do not limit tool life. Because the lands are concentric, the threads on the tap help guide the tool into the threads on the workpiece as they are cut.

Eccentric relief means that the lands are cut to an arc that is not on center with the bulk of the tool. This type of relief provides the best clearance between the tap and the thread being cut. Because the tool doesn’t rub against the material, friction can be minimized.

Con-eccentric relief is a combination of the other two styles. A small part of the land remains concentric at the leading edge while the rest of the relief is eccentric. This style provides a balance between reduced friction, as provided by eccentric relief, and tool guidance, as provided by concentric relief.

Concentric relief and, to a lesser degree, con-eccentric relief taps rub the workpiece material as the tool enters and exits the hole, causing friction, which in turn produces heat. Heat diminishes tool life. As a result, premium taps are most often made with eccentric relief. “The higher the relief, the lower the friction of the tool,” Haenle said. “Therefore, a higher relief results in less wear and longer tool life. However, a lower relief guides the tool better in the axial direction because it has less tendency to cut in the radial direction.”

Premium taps are not for all machines. A high-end tap will not guide itself when creating the thread. Therefore, taps with eccentric relief require the machine’s feeding mechanism to be highly accurate.

“In newer CNC machines, you can use taps with higher relief angles,” Haenle said. “On the other hand, when using older equipment or drilling machines with less rigidity and with standard tapping chucks, a smaller relief angle helps to guide the tap better.”

Courtesy of OSG Tap & Die

OSG’s Hy-Pro tap design for vertical and horizontal tapping for the oil and power industry. The VXL tap (left) has a fast spiral-flute design for vertical machining. The HXL tap, with a slower spiral to break up chips, is for horizontal machining.

Tap manufacturers understand the balance between edge strength and the cutting edge’s ability to shear the workpiece. “For performance taps, rake angles are determined by the intended work material, with higher angles for softer materials and lower angles for harder materials,” Strauchen said. “It is a give-or-take scenario between rake and relief. Too much of both makes for a sharp edge and free cutting face with poor strength. The reverse is a stronger edge with low shear that will generate significantly more fiction.”

To develop the proper geometry for a given application, tap designs can be complex. OSG has designed taps for vertical and horizontal machining: the Hypro HXL for horizontal and VXL for vertical. “We coupled a higher rake with a higher spiral to produce longer chips, which is necessary for chip evacuation in deep-hole vertical applications,” Strauchen explained. “With a unique flute form, we are able to create a tightly bound chip that peels away from the tap and holder when exiting the hole.”

Horizontal machining, which can use gravity as an advantage, requires different geometries than vertical machining, he continued. “We lowered the rake angle and slowed the helix to induce a short, broken chip easily flushed out in horizontal applications. This design not only eliminates the bird nesting issue, but also extends tool life.”

Many tap issues can be solved before your finger reaches for the cycle start button. Knowing a little about tap design helps to eliminate the mystery and fear of tapping. CTE

Learn more about tapping

Get more information on tapping by viewing an Interactive Report on www.ctemag.com (on the home page and also accessible through the “News and Events” drop-down menu).

About the Author: Dave Nelson is an application engineer for Productivity Inc. and a freelance technical writer. He works in the Omaha, Neb., office of the Minneapolis-based machine tool distributor. Contact him by e-mail at [email protected].

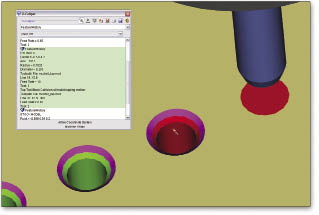

Courtesy of CGTech

An invalid tapping motion being identified in Vericut.

With its higher feed rates and greater consequences for failure than other metalcutting operations, tapping can be a high-stress operation. One way to reduce that stress is by using software to simulate the process to identify and correct problems before they start. For example, Vericut 6.2 from CGTech, Irvine, Calif., has a new feature that simulates and analyzes tapping operations. Tapped holes are visually differentiated from other drilled, bored and reamed holes. Vericut checks that the correct feed rate and tapping direction are used, and also detects if the hole to be tapped is too small.

A feature called X-Caliper allows operators to measure thickness, volume, depth, gaps, distances, angles, hole diameters, corner radii and scallop heights. Vericut can directly measure the depth of blind-holes, countersunk holes and the top and bottom radii of a cone. Additionally, picking a hole on a model file will display the center point. X-Caliper can also measure the distance between the tool and the stock, and show the thread features of a tapped hole, such as pitch threads per inch.

—Alan Rooks, Editorial Director

Contributors

CGTech

(949) 753-1050

www.cgtech.com

Guhring Inc.

(800) 776-6170

www.guhring.com

Kennametal Inc.

(800) 446-7738

www.kennametal.com

OSG Tap & Die Inc.

(800) 837-2223

www.osgtool.com

Related Glossary Terms

- blind-hole

blind-hole

Hole or cavity cut in a solid shape that does not connect with other holes or exit through the workpiece.

- clearance

clearance

Space provided behind a tool’s land or relief to prevent rubbing and subsequent premature deterioration of the tool. See land; relief.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- flutes

flutes

Grooves and spaces in the body of a tool that permit chip removal from, and cutting-fluid application to, the point of cut.

- inches per minute ( ipm)

inches per minute ( ipm)

Value that refers to how far the workpiece or cutter advances linearly in 1 minute, defined as: ipm = ipt 5 number of effective teeth 5 rpm. Also known as the table feed or machine feed.

- land

land

Part of the tool body that remains after the flutes are cut.

- metalcutting ( material cutting)

metalcutting ( material cutting)

Any machining process used to part metal or other material or give a workpiece a new configuration. Conventionally applies to machining operations in which a cutting tool mechanically removes material in the form of chips; applies to any process in which metal or material is removed to create new shapes. See metalforming.

- pitch

pitch

1. On a saw blade, the number of teeth per inch. 2. In threading, the number of threads per inch.

- rake

rake

Angle of inclination between the face of the cutting tool and the workpiece. If the face of the tool lies in a plane through the axis of the workpiece, the tool is said to have a neutral, or zero, rake. If the inclination of the tool face makes the cutting edge more acute than when the rake angle is zero, the rake is positive. If the inclination of the tool face makes the cutting edge less acute or more blunt than when the rake angle is zero, the rake is negative.

- relief

relief

Space provided behind the cutting edges to prevent rubbing. Sometimes called primary relief. Secondary relief provides additional space behind primary relief. Relief on end teeth is axial relief; relief on side teeth is peripheral relief.

- tap

tap

Cylindrical tool that cuts internal threads and has flutes to remove chips and carry tapping fluid to the point of cut. Normally used on a drill press or tapping machine but also may be operated manually. See tapping.

- tapping

tapping

Machining operation in which a tap, with teeth on its periphery, cuts internal threads in a predrilled hole having a smaller diameter than the tap diameter. Threads are formed by a combined rotary and axial-relative motion between tap and workpiece. See tap.

- threading

threading

Process of both external (e.g., thread milling) and internal (e.g., tapping, thread milling) cutting, turning and rolling of threads into particular material. Standardized specifications are available to determine the desired results of the threading process. Numerous thread-series designations are written for specific applications. Threading often is performed on a lathe. Specifications such as thread height are critical in determining the strength of the threads. The material used is taken into consideration in determining the expected results of any particular application for that threaded piece. In external threading, a calculated depth is required as well as a particular angle to the cut. To perform internal threading, the exact diameter to bore the hole is critical before threading. The threads are distinguished from one another by the amount of tolerance and/or allowance that is specified. See turning.

- through-hole

through-hole

Hole or cavity cut in a solid shape that connects with other holes or extends all the way through the workpiece.