Hard metal machines

Hard metal machines

All metals are not created equal. Therefore, neither are the machine tools for cutting them. Parts for extreme aerospace applications, such as in engines, landing gear and flap tracks, must be made of a heat- and corrosion-resistant metal, which typically has a high Young's elasticity/" data-glossary-id="141729" data-glossary-teaser="Measure of rigidity or stiffness of a metal, defined as a ratio of stress, below the proportional limit, to the corresponding strain. Also known as Young’s modulus." title="Measure of rigidity or stiffness of a metal, defined as a ratio of stress, below the proportional limit, to the corresponding strain. Also known as Young’s modulus." aria-label="Glossary: modulus of elasticity">modulus of elasticity and is difficult to machine. These include titanium, stainless steel and high-nickel alloys.r The "hard metal" machines that process the parts must be stiff, typically requiring a large mass, and have a large servomotor to create lots of thrust. They also need a high-torque spindle to effectively move the cutter through the material and a high thrust load on the axes of the ballscrews, which often have a low 8mm pitch, to offer an effective mechanical advantage, according to Scott Walker, president of machine tool builder Mitsui Seiki USA Inc., Franklin Lakes, N.J. He explained that the machines are built that way because aerospace customers typically run them slower than 600 rpm, require around 2,000 ft.-lbs. of torque and take maximum chip loads from 0.002 to 0.006 ipt. "So you build this big, rugged machine," Walker said.

Machine tool design and recommendations for processing difficult-to-cut metals to make aerospace parts.

All metals are not created equal. Therefore, neither are the machine tools for cutting them. Parts for extreme aerospace applications, such as in engines, landing gear and flap tracks, must be made of a heat- and corrosion-resistant metal, which typically has a high Young's elasticity/" data-glossary-id="141729" data-glossary-teaser="Measure of rigidity or stiffness of a metal, defined as a ratio of stress, below the proportional limit, to the corresponding strain. Also known as Young’s modulus." title="Measure of rigidity or stiffness of a metal, defined as a ratio of stress, below the proportional limit, to the corresponding strain. Also known as Young’s modulus." aria-label="Glossary: modulus of elasticity">modulus of elasticity and is difficult to machine. These include titanium, stainless steel and high-nickel alloys.

The "hard metal" machines that process the parts must be stiff, typically requiring a large mass, and have a large servomotor to create lots of thrust. They also need a high-torque spindle to effectively move the cutter through the material and a high thrust load on the axes of the ballscrews, which often have a low 8mm pitch, to offer an effective mechanical advantage, according to Scott Walker, president of machine tool builder Mitsui Seiki USA Inc., Franklin Lakes, N.J. He explained that the machines are built that way because aerospace customers typically run them slower than 600 rpm, require around 2,000 ft.-lbs. of torque and take maximum chip loads from 0.002 to 0.006 ipt. "So you build this big, rugged machine," Walker said.

Courtesy of Mitsui Seiki USA

A custom 1,900mm-dia. pallet for a helicopter rotor hub component is produced in a Mitsui Seiki Model HU100-5XL 2m trunnion machine.

On the other hand, he pointed out that "soft metal" machines, which might be used exclusively for aluminum applications, require agility. This is achieved by removing component mass and equipping the machines with a 15,000- to 20,000-rpm or higher spindle and high-pitch ballscrews, which go up to 24mm, to enhance acceleration/deceleration.

"I typically go to direct-drive motors on the A and B axes instead of having mechanical drives or ring-gear drives because you want to have lots of reversal speed when going around corners in soft metals," he added. "They're two different machine designs."

Although it's possible to cut difficult-to-machine metals on a general-purpose machine, there are consequences. Cutting those metals on such a machine would wear it out in about 20,000 hours, whereas cutting aluminum would enable the machine to last 50,000 to 60,000 hours, according to Walker. Conversely, a hard metal machine lasts 75,000 hours—a 12-year, three-shift depreciation schedule—and holds its accuracy throughout the entire life of the machine, which for a trunnion machine is 0.001 " true position in the cube.

Betting Big

Speculating during a lull in business last year that there would be a demand for them, Mitsui Seiki USA built eight 5-axis, fixed-spindle, trunnion-style machines in 6 months without having purchase orders and sold all of them to aerospace part manufacturers. "It was a good gamble," Walker said.

The trunnion machines include three models: HU100-5X with a maximum part swing of 1,500mm (59 ") and a maximum part height of 1,050mm (41 "), HU100-5XL with a maximum part swing of 2,000mm (78 ") and a maximum part height of 1,200mm (47 ") and HU100-5XLL with a maximum part swing of 2,500mm (98 ") and a maximum part height of 1,200mm (47 ").

Courtesy of Mitsui Seiki USA

Four of the eight large 5-axis, fixed-spindle, trunnion-style machines Mitsui Seiki USA built in the last half of 2012 in anticipation of market demand.

Walker pointed out that the increased interest in trunnion-style machines is based on two trends in the aerospace industry. The first is more parts are being designed as monolithic components rather than assembling multiple parts together with rivets, bolts or other means.

"Today, the capability to move stuff around on the screen and convert that design into part programs has given CAD designers a lot more flexibility to make one part instead of bolting three or four parts together," Walter said, noting those types of parts are a good fit for trunnions.

The other trend is to add more sophisticated geometry to single-piece parts typically made of Ti6Al4V because they are structurally sound, easy to assemble, lightweight and corrosion-resistant, according to Walker. This is accomplished mostly by nonmachining processes, such as sandwiching titanium between composite sheets, heating it to form a die and eliminating rivets from the multiple components fastened together.

Exacta Aerospace is one manufacturer of aerospace structural parts that is machining more monolithic designs. The Wichita, Kan., company produces many parts made of Ti6Al4V and heat-treated 138 stainless steel, as well as a bit of Inconel, for practically all of the aircraft OEMs, noted Kelly Eilerts, 4/5-axis supervisor. Rather than complexity, the size of monolithic parts is more of an issue for Exacta, which recently purchased a Mazak 5-axis Vortex 1400V/160 II vertical machining center with two rotating axes in the spindle head and an X-axis travel of about 65 " to accommodate the parts being machined and the ones on the horizon.

"We purchased it so we could get bigger titanium parts because there are quite a few out there," Eilerts said. Other machines at Exacta include 4-axis a81M and a82M horizontal machining centers from Makino, which have 8,000-rpm spindles that produce 740 ft.-lbs. of torque and are arranged in a work cell to machine titanium parts up to nearly 40 " long.

Courtesy of Exacta Aerospace

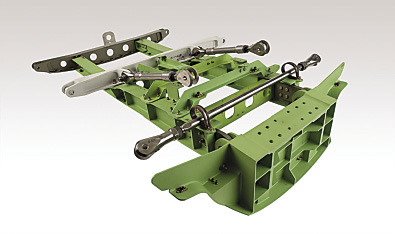

An assembly Exacta manufactures has two titanium details that measure about 3 ' in length: one is painted white toward the middle of the assembly and the other is at the back and painted dark green.

As monolithic parts get larger, the challenge of reaching all the machined features increases. For example, combining several parts in one can create deep pockets, Eilerts noted, adding that the company applies cutting tools up to 16 " long in its Makino HMCs. "That challenge is something we fight—happily," he said. "It's fun and something we're definitely growing with right now."

Nonetheless, part complexity is a concern with monolithic parts as designers take advantage of the capabilities of the latest 3-D modeling systems, according to Randal Von Moll, director of technical sales for machine builder MAG IAS LLC, Hebron, Ky. "One of the jokes in the aircraft parts making business is we've never seen a straight line on any part," he said. "In the last few years, part shapes have gotten much more exotic, especially on the defense side. This can have a dramatic effect on what types of machine to use to efficiently manufacture the parts."

Going Gantry

The increasing complexity of aerospace parts practically mandates 5-axis machining. One option to help satisfy the increased demand for titanium and exotic steel alloy parts is MAG's 5-axis XTi gantry profilers, which have up to five spindles. The machine's basic configuration includes a pair of floor-mounted rails, which have guide ways, a drive rack and feedback systems for the X-axis, and the foundation-mounted work plate between the rails, Von Moll explained.

In addition to 5-axis contouring, five-sided machining is advantageous to minimize fixturing when producing aerospace components. "Just because you have a 5-axis machine doesn't mean you can do five-sided machining," Von Moll said. He pointed out that newer 5-axis horizontal profiling machines, such as MAG's H series, can do five-sided work because of the A/C-axes spindle head. However, for oversize parts, such as a 50 '-long wing span or skin panel, a very large, open vertical machine is required because it has the largest working volume. "To build a horizontal machine of that scale is cost-prohibitive," Von Moll said.

A MAG gantry machine can have one to five spindles, with a three-, four- or five-spindle arrangement being common. According to Von Moll, having multiple spindles on a machine lowers the cost per part compared to running multiple single-spindle machines. "In many cases, a shop needs a dedicated operator to run each of the single-spindle machines," he said, "where there is only one person operating the large gantry machine even though it could be producing five identical parts simultaneously."

Courtesy of Mitsui Seiki USA

Mitsui Seiki's HU100-5XL machine offers a maximum part swing of 2,000mm and can machine parts up to 1,200mm in height and weighing 2,000 kg (capacity for 3,000-kg parts is optional).

Courtesy of Exacta Aerospace

Exacta Aerospace's a81M/a82M hard metal Makino Machining Complex produces titanium parts up to 40" long.

Von Moll noted the gantry machines are well-suited for challenging materials. MAG is building eight of those machines, for example, for Aerospace Dynamics International Inc., Valencia, Calif., to support the increasing demand for titanium parts. As reported in CTE's online IMTS 2012 coverage, ADI announced at the show that it will increase its titanium machining capacity about 40 percent to support next-generation airplane programs with a new 120,000-sq.-ft. facility and a $36 million investment to buy the gantry profilers. Upon completion, the expansion will give ADI about 600,000 sq. ft. under roof and require more than 200 new employees to staff the operation.

"We are producing some significant titanium assemblies and side-frame components for the Airbus A350 that require lots of heavy machining, and we expect these machines to fill a big role in reaching our contracted ramp-up rates," said ADI President and CEO John T. Cave II.

With the increasing rate of aircraft production, "there are not enough spindles to produce all the needed titanium parts in the next 10 years," said Ed Hatcher, director of manufacturing for ADI, "but we are doing our part."

According to MAG, the newer 5-axis gantry design utilizes the same high-stiffness frame as the 3-axis XTi, which achieved a metal-removal rate of more than 90 cu. in. per minute in a runoff for ADI. The parts manufacturer has two of those 3-axis profilers.

Spindle Selection

In addition to the machine type, the type of spindle taper interface is an important consideration when machining aerospace parts. Exacta Aerospace uses numerous types of spindle taper interfaces, including BT40, CAT 40 and 50, KM63 and HSK 80 and 100, but only the HSKs are found on the hard metal machines because of their enhanced rigidity, Eilerts said. "As we're buying new machinery to handle some of this titanium work we've got coming, HSK is the only option for us."

Walker noted Mitsui Seiki offers CAT 50, KM4X 100 and HSK 100, 125 and 160 spindle taper interfaces, each with a specific bending-moment capability. "The HSK and KM spindle tapers have higher bending moments, which is what you want when you have long tools cutting hard metals," he said. "If you have long-reach parts and you're going to run those parts for a while, you must go with a different interface than CAT 50."

Courtesy of MAG

ADI machines titanium parts on a dual-gantry, 10-spindle, 3-axis XTi profiler from MAG. Each spindle delivers up to 68 hp and produces up to 1,860 ft.-lbs. (2,523 Nm) of torque. In test cuts, the profiler's metal-removal rate when machining titanium was more than 90 cu. in. per minute.

However, if an end user pushes HSK tooling too hard, the tool will break without warning and potentially "come flying out of the machine," Walker said. "You are not going to hear it because the drawbar forces are so high and you're holding that tool in the spindle so rigidly that either you've got the tool or you break it."

Conversely, a machinist can hear a tool separating from a BT or CAT holder before the tool breaks, he added. "When I was running production aerospace parts, I would just sit on the feed-rate knob and keep bumping it up to get my cycle time down until it didn't sound good," Walker said. "Then I backed off and that would be the feed for that particular tool. You can't do that with HSK or KM, and you need to closely watch your calculated bending moment and be sure not to exceed it while cutting."

Courtesy of MAG

MAG's PMT (precision mill and trim) vertical gantry mill is shown with the high-rail configuration and programmable workholding system. The machine is suitable for 5-axis machining and five-sided part access. Programmable machine-head-changing capability accommodates an auxiliary waterjet system.

Although an HSK 63A or HSK 100A interface is suitable for efficient, high-power aluminum machining when applying a tool that extends 6 " or more, MAG's Von Moll recommends a more massive interface, such as HSK 125A, when cutting titanium with a similar tool. "It's similar in size and scope to the old CAT 60, which was originally designed for holding very large tools and taking heavy cuts," he said.

As metals continue to be developed that enhance part capability in extreme environments, machine tool design, as well as the entire machining system, will continue to evolve to tackle those harder, more resilient metals that have a higher modulus of elasticity coefficient. And whether it's a machine tool, cutting tool, workholder or toolpath engine, the aerospace part manufacturers that avoid extinction are the ones who follow the sentiment of Eilerts at Exacta Aerospace about the need for continuous improvement: "We never find something we're happy with and just stop there." CTE

About the Author: Alan Richter is editor of CTE. He joined the publication in 2000. Contact him at (847) 714-0175 or [email protected].

Courtesy of Mitsui Seiki USA

Mitsui Seiki USA refurbishes jig borers, such as this Model 6CNII.

Refurbishing 'mother' machines

Because of their ultraprecise accuracy, jig borers are "mother" machines—ones that machine tool builders employ to make components for their machines, including gearboxes, pallets and spindle housings. "Experienced operators can machine to 1µm tolerances on a jig borer," said Mitsui Seiki USA Inc.'s Scott Walker. (Japan-based Mitsui Seiki Kogyo Co. Ltd. is one of the few remaining builders of jig borers.)

Walker noted many jig borers are also used for reboring aircraft gearboxes. Typically, critical gearbox bores are fitted with a bushing, which the machine bores to its correct size. In addition, the demand for new fuel-efficient jet engines is increasing the demand for ultraprecision machining applications to achieve the components' stringent requirements, according to Walker. New helicopters are contributing to the push for jig boring capabilities as well.

Although their controls eventually become outdated, Walker said jig borers don't really wear out, except for the tabletop. This is because operators often stone the top to remove burrs and debris, rounding it over time.

However, when a Mitsui Seiki jig borer does need refurbishment—usually after being in service for 25 years—it's cost-prohibitive to ship it to Japan, according to Walker. Machine rebuilders can be found in the U.S. to perform the work, but some OEMs require a qualified supplier. "Being a supplier to those segments, we have the qualifications in place to provide a certified machine," he said.

As a result, Mitsui Seiki USA introduced its jig borer refurbishment service after acquiring the necessary equipment. In addition to rescraping the table surface, essentially the machine's master gage, the service typically includes refitting the quill assembly, replacing spindle bearings, integrating a new FANUC control, rewiring the electrical components and replacing outdated motors and drives.

Walker noted the company can refurbish a couple of machines a year, and its first one was shipped back to Lockheed Martin in December.

—A. Richter

Contributors

Aerospace Dynamics International Inc.

(661) 257-3535

www.marvingroup.com

Exacta Aerospace

(316) 941-4200

www.exactaaerospace.com

MAG IAS LLC

(859) 534-4600

www.mag-ias.com

Mitsui Seiki USA Inc.

(201) 337-1300

www.mitsuiseiki.com