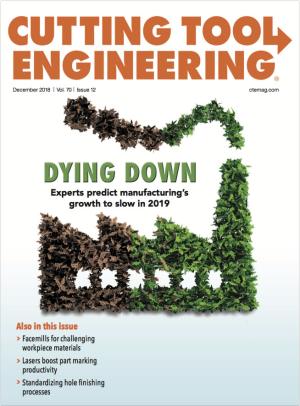

Once again, our December issue includes an annual outlook and recap report, which begins on Page 22 of the print and digital versions. For the article, I gathered information from economic authorities who cover the aerospace, automotive and energy industries, as well as the manufacturing sector as a whole.

In connection with two other articles I wrote, the Talking Shop column on Page 16 and the Shop Operations column for the January issue, I also asked the sources about their expectations for their business areas in 2019.

For the former, Nadine Crauwels, president of AB Sandvik Coromant, replied, “That is the billion-dollar question.” She elaborated that growth in 2019 will flatten out compared with the relatively high levels previously seen in the machining world.

“There will be some growth but not as large as we have seen in the past year and a half,” Crauwels said. “But that still means there are a lot of opportunities out there.”

Simon Whitton, regional division manager for North America at KUKA Robotics Corp., also sees demand for robots continuing to increase. At the forefront of robot adoption are South Korea, Japan and China. “They are driving this huge uptick in the use of robotics, principally because of the shortage of labor,” he said.

Although China, with a population of more than 1.4 billion people, has an extremely large labor pool to tap into, Whitton said social issues play a role in determining where people will work. Because of the one-child policy in effect while he lived in China for eight years, Whitton witnessed what he described as “the little king syndrome. That’s where you have a single grandchild and four grandparents, and the expectations for this grandchild were not to work in a factory.” The push to have a child go to a university to become “somebody of significance” started to bite into the supply chain of production workers. “Hence, this massive drive and uptick in robotics in China,” he added. That sounds familiar.

Nonetheless, Whitton sees the automotive industry, which according to the International Federation of Robotics consumes about 35 percent of the robots produced, reducing the number of model launches next year. As a result, he expects the market for robots to grow less in 2019.

One place the U.S. automotive sector continues to boom in is the Southeast, said Joe Gemma, chief regional officer at KUKA. There, manufacturers and automotive suppliers turn to robots to cut costs and improve efficiency. But, he added, those companies may not have the expertise to apply robots as effectively as they could.

To increase manufacturers’ effectiveness, KUKA partnered with the Greenville (South Carolina) Technical College Center for Manufacturing Innovation. “Greenville is a central point for many of our clients in the region,” Gemma said. “The tech center works with many other great companies, so it makes sense to partner with the center to bring a new level of robotics training to the region.”

That training should help reduce the shortage of robotics technicians. And when a manufacturer faces a production stoppage because of a robot problem, a robotics technician is somebody of significance.

Related Glossary Terms

- robotics

robotics

Discipline involving self-actuating and self-operating devices. Robots frequently imitate human capabilities, including the ability to manipulate physical objects while evaluating and reacting appropriately to various stimuli. See industrial robot; robot.

- tap

tap

Cylindrical tool that cuts internal threads and has flutes to remove chips and carry tapping fluid to the point of cut. Normally used on a drill press or tapping machine but also may be operated manually. See tapping.