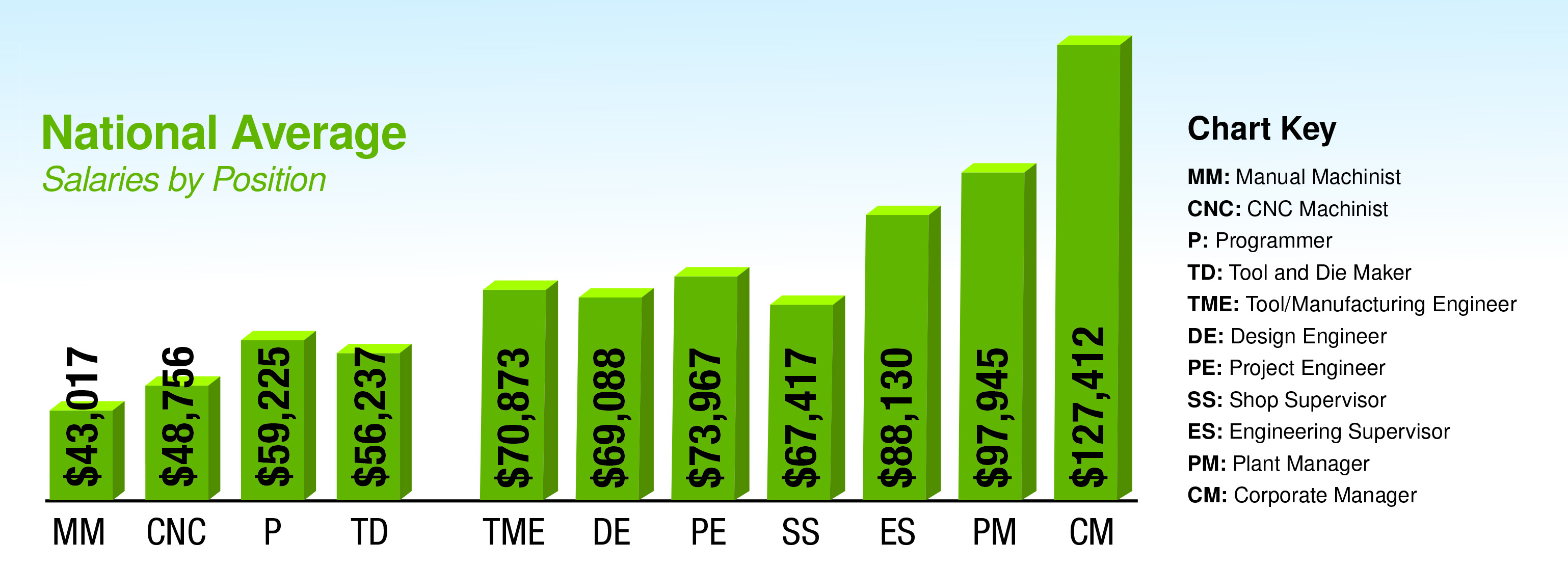

In sharp contrast to the previous survey from 2016, Cutting Tool Engineering’s 10th Biennial Salary Survey reveals that metalworking professionals are receiving more pay and benefits while demand for skilled workers remains robust and unemployment is low. Based on the national averages, all positions—from manual machinists to corporate managers—saw increases.

While all positions experienced double-digit percentage increases in salaries—with the exception of CNC machinists at 7.4 percent—engineering supervisors realized the biggest percentage gain at 20.8 percent. As usual, corporate managers came out on top of the heap for actual salary. Their average salary of $127,412 reflects an increase of 14.6 percent compared with 2016.

Possibly to attract and retain workers, a significantly higher percentage of metalworkers are receiving benefits from employers. This year’s survey indicates that a higher percentage of workers in all positions are receiving health and dental plans, profit sharing and training. Looking at health insurance, for example, all positions showed sizable gains in this year’s survey compared with 2016. The percentage of design engineers receiving the benefit rose from 26 to 68 percent, followed by the percentage of engineering supervisors, increasing from 22 to 59 percent.

Although the percentage of tool and die makers who have a health plan rose to 40 percent in 2018 compared with 25 percent in 2016, a majority (60 percent) of them still do not have health plans.

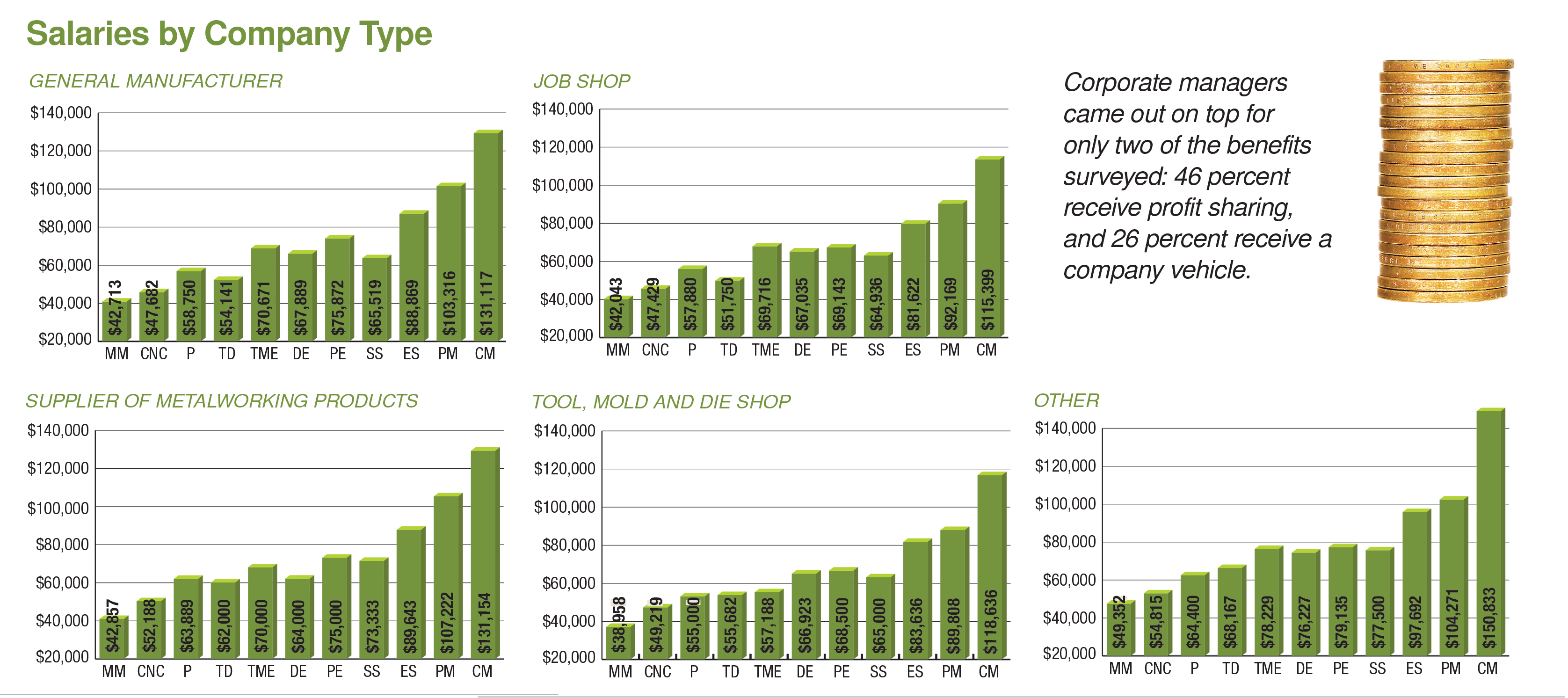

The only benefit that saw a reduction in some positions is the use of a company vehicle. Fewer manual machinists, tool and die makers and corporate managers receive one. While 26 percent of corporate managers still receive a company vehicle, the percentage was 33 in 2016 and 39 in 2014.

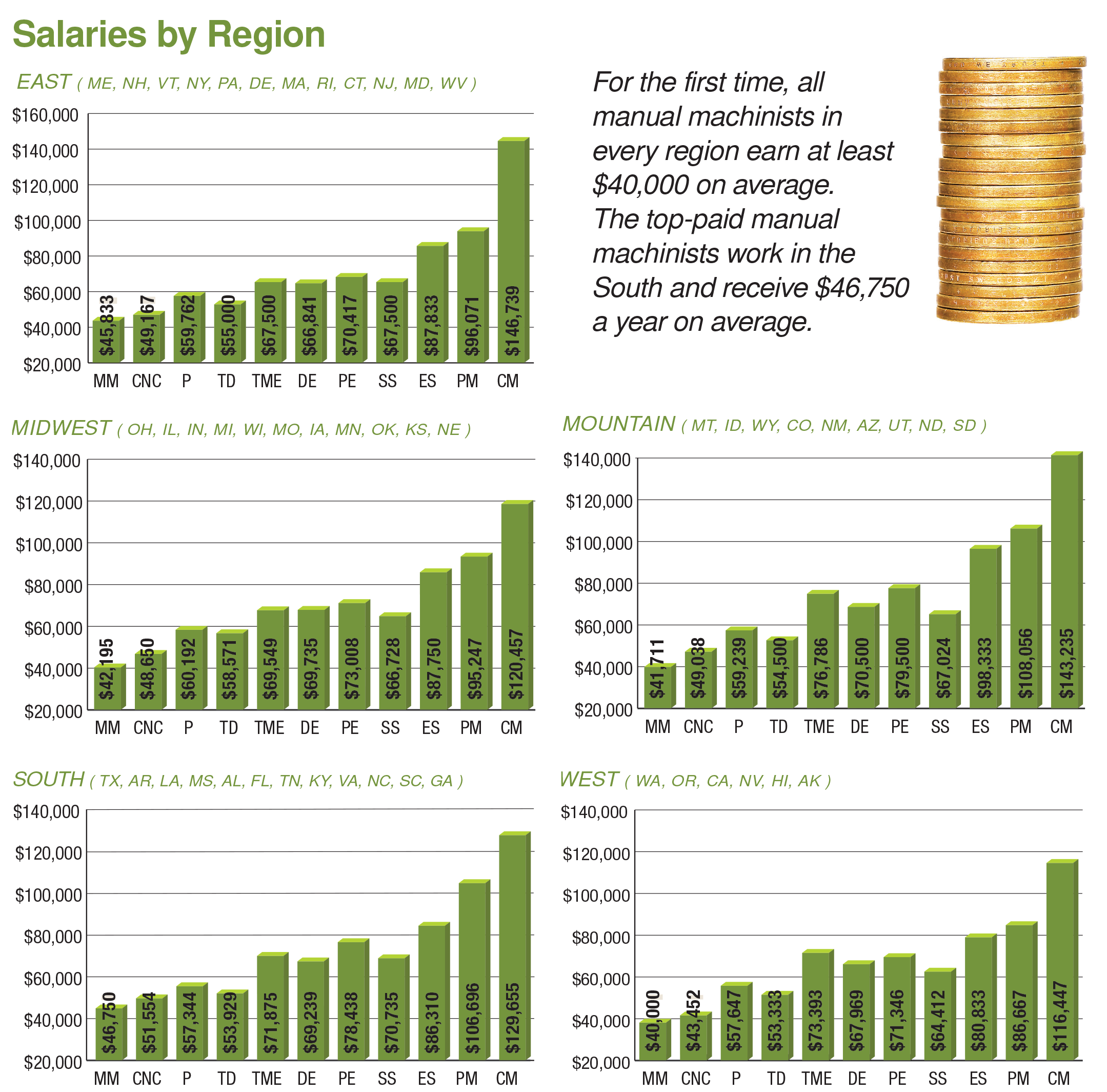

For whatever reason, not all regions and company types followed the national average’s upward trajectory for pay. Manufacturers in the West decreased the compensation for manual machinists, CNC machinists, programmers, shop supervisors and engineering supervisors. Salaries for only three (manual machinist, tool and die maker and design engineer) of the 11 positions covered in the survey increased at tool, mold and die shops. Meanwhile, programmers at those shops received the same amount—$55,000—as they did 2 years ago, which is an effective pay reduction when adjusted for inflation.

For companies with 100 or more employees, design engineers, plant managers and corporate managers actually received fewer dollars in their paychecks compared with the 2016 survey.

Similar to the previous three biennial surveys, CTE used email to collect survey data from owners and managers of parts manufacturing companies who subscribe to the magazine. The email directed them to an online survey form that requested average annual salaries and benefits for themselves and their employees.

For the 2018 survey, CTE received wage and benefits information for the manufacturing professionals at 223 companies.

The average salary was calculated according to the arithmetic mean. For example, if four recipients indicated that their programmers earned average annual salaries of $46,000, $59,000, $51,000 and $53,000, the mean would equal $52,250; (46,000 + 59,000 + 51,000 + 53,000) ÷ 4 = 52,250.

The benefit percentages were calculated by dividing the total number of positive replies for a specific benefit by the total number of respondents. For example, if 84 respondents indicated that their CNC machinists receive company-paid dental insurance, the percentage receiving that benefit would be 38 percent (84 ÷ 223 = 0.377).

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- metalworking

metalworking

Any manufacturing process in which metal is processed or machined such that the workpiece is given a new shape. Broadly defined, the term includes processes such as design and layout, heat-treating, material handling and inspection.

- sawing machine ( saw)

sawing machine ( saw)

Machine designed to use a serrated-tooth blade to cut metal or other material. Comes in a wide variety of styles but takes one of four basic forms: hacksaw (a simple, rugged machine that uses a reciprocating motion to part metal or other material); cold or circular saw (powers a circular blade that cuts structural materials); bandsaw (runs an endless band; the two basic types are cutoff and contour band machines, which cut intricate contours and shapes); and abrasive cutoff saw (similar in appearance to the cold saw, but uses an abrasive disc that rotates at high speeds rather than a blade with serrated teeth).