10% cycle time reduction, 4 times better surface quality

Myles Tool Company, Sanborn, NY, since 1977 has specialized in producing standard and special carbide cutting tools for the aerospace, automotive and medical sectors. A one-stop shop for standard tools, regrinds, and special tools made to customer requirements, Myles has grown by investing in new machines and high quality equipment.

VIDEO

View video supplement looking at how an ANCA MX7 Linear CNC tool grinder helped reduce cycle times. Video courtesy ANCA.

Looking for a way to reduce grinding cycle times and improve cutting tool quality in order to satisfy customer requirements, Myles most recently invested in an ANCA MX7 Linear CNC tool grinder with linear motors. Over the years the company purchased a total of 13 ANCA CNC tool and cutter grinding machines. Seven of these machines are the MX7 model.

Joe Adams, plant manager of the grinding shop at Myles Tool, is very knowledgeable in cutting tool design and production. He knows the process and the machines in detail.

The ANCA MX7 Linear CNC tool and cutter grinder improved flute surface finish from 0.8 Ra to 0.2 Ra. Images courtesy ANCA.

“We were looking for capacity and an ability to produce a polished finish on the flutes of one of our aluminium tools,” Joe said. ”The MX7 Linear CNC grinder was delivered a few months ago and has been producing tools of exceptional quality to tight dimensional tolerances without any problems since its first day of operation. Normally, I prefer not to buy first-generation machines, but after talking to ANCA and seeing the machine in operation, I was confident it would grind to the finishes I was looking for.”

Asked about any differences he has noted between the MX7 ballscrew and linear motor machine, Joe commented, “When using the same grinding wheels, tool file, feeds and speeds, the surface finish is better on a tool ground on the MX7 Linear when compared to the tools ground on an MX7 ballscrew machine.”

Joe believes the MX7 Linear machine is superior to a machine driven by a ballscrew, “because you do not have to deal with wear, backlash and the transition is smoother. Ball screw wear is a big factor to us because we run a 24/7 operation. We cannot have any failures or unacceptable parts.”

The flute face from a tool ground on the MX7 ballscrew machine can be as low as 0.8 Ra (roughness average), but the flute face measured on a tool ground on the MX7 Linear measures even lower at 0.2 Ra.

“We are seeing much better finishes with the linear motor machine than we could achieve with the ball screw machines, especially for our aluminium tools,” Joe said. The product is an end mill range with variable helix and variable index, two- and three-flute. Joe added a secondary fluting operation to polish the flutes for improved chip flow using an 800-grit wheel.

Range of carbide tools by Myles Tool.

This final grinding pass, although an added move, adds no time to the cycle.

There is actually a reduction in cycle time of up to 10 percent when grinding on the MX7 Linear machine. Joe noted, “The reduction in cycle time from the MX7 Linear machine—for batches of up to 5,000 pieces—is a significant saving in cycle time for the company, allowing us to deliver high quality tools in minimum time.”

Myles has found a few advantages to the ANCA Linear compared to ball screws or other linear motors.

Flatbed style linear motors used in grinding machines typically have a back-iron in their magnetic circuit increases the down-forces and creates cogging. Cogging results in reduced surface finish quality. This tremendous down-force on the bearings can cause components to wear faster, decreasing efficiency.

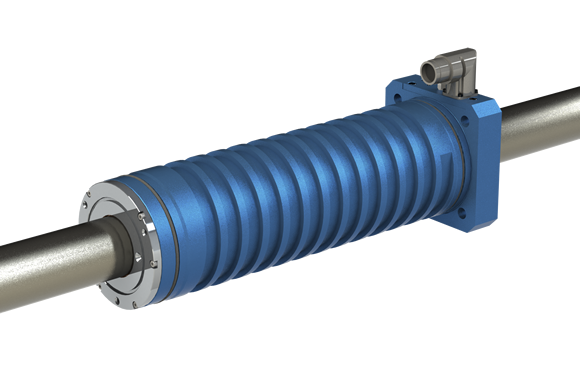

The LinX® Linear Motor’s even force over entire stroke provides unprecedented motion performance, and because of its direct drive nature the motor can track motion commands more accurately and repetitively to achieve better surface finish. In addition to the improved surface finish, the LinX® Linear Motor also enhances the cycle time due to its higher acceleration and faster traverse speed.

The linear motor is very compact under the way cover and avoids ball screw stick-slip and wear issues while providing 10 percent faster cycle times.

The key is the LinX cylindrical design.

The LinX® Linear Motor consists of a shaft containing magnets and a forcer containing wound copper coils. The symmetric design results in zero attractive forces between the forcer and shaft, greatly reducing the loading requirement on support bearings. The thermal barrier design separates and removes heat from the motor, eradicating thermal growth for the machine. So ANCA Linear machines don’t require a dedicated chiller, reducing power and floor space requirements. The traditional flatbed linear motor typically requires a separate chiller for thermal stability.

The MX7 Linear at Myles Tool uses the same coolant system and chiller as the MX7 ballscrew machines. No special modifications were needed to the coolant system or the chiller unit to accommodate the MX7 Linear machine, Joe said. “We have had no thermal concerns with the MX7 Linear. And the polymer concrete base on ANCA machines contributes significantly to the thermal stability of the machine.”

With LinX®’s simple construction, non-critical air gap and no physical contact between shaft and forcer, machine manufacturers can greatly simplify installation, reduce maintenance and extend machine life. The LinX®’s design allows it to easily replace ball screws in existing machines.

Rendering of the ANCA Motion linear motor, an energy- and space-efficient innovation in drives well-suited to precision machining applications.

Due to its simple construction, only one or two supports are required at the shaft ends depending on its orientation. Not only has the axis installation time been reduced by more than 200 percent when compared to ball screws, but the installation of LinX® motors is much safer than flatbed linear motors.

In Myles’ experience, the LinX® Linear Motor provided improved performance at lower cost with excellent efficiency when compared to ball screws and flatbed linear motors. The standalone thermal stability, high speed and acceleration, zero down forces and the ability to achieve IP69K protection make LinX® an ideal solution for precision machine tool motion.

Case study submitted by ANCA Inc., 31129 Century Drive, Wixom, MI, 48393. Phone: 248-926-4466. Website: www.anca.com.

Related Glossary Terms

- backlash

backlash

Reaction in dynamic motion systems where potential energy that was created while the object was in motion is released when the object stops. Release of this potential energy or inertia causes the device to quickly snap backward relative to the last direction of motion. Backlash can cause a system’s final resting position to be different from what was intended and from where the control system intended to stop the device.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- flutes

flutes

Grooves and spaces in the body of a tool that permit chip removal from, and cutting-fluid application to, the point of cut.

- fluting

fluting

Cutting straight or spiral grooves in drills, endmills, reamers and taps to improve cutting action and remove chips.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- linear motor

linear motor

Functionally the same as a rotary motor in a machine tool, a linear motor can be thought of as a standard permanent-magnet, rotary-style motor slit axially to the center and then peeled back and laid flat. The major advantage of using a linear motor to drive the axis motion is that it eliminates the inefficiency and mechanical variance caused by the ballscrew assembly system used in most CNC machines.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- precision machining ( precision measurement)

precision machining ( precision measurement)

Machining and measuring to exacting standards. Four basic considerations are: dimensions, or geometrical characteristics such as lengths, angles and diameters of which the sizes are numerically specified; limits, or the maximum and minimum sizes permissible for a specified dimension; tolerances, or the total permissible variations in size; and allowances, or the prescribed differences in dimensions between mating parts.