Researchers have identified 43 previously unknown forms of carbon that they think are stable and superhard. Theoretically, these superhard materials can slice, drill and polish other materials and potentially could create scratch-resistant coatings to protect expensive equipment from damage.

“Diamonds are right now the hardest material that is commercially available, but they are very expensive,” said Eva Zurek, professor and chemist at the University at Buffalo and one of the researchers. “I have colleagues who do high-pressure experiments in the lab, squeezing materials between diamonds, and they complain about how expensive it is when the diamonds break.”

She devised the study and co-led it with Stefano Curtarolo, professor of mechanical engineering and materials science at Duke University. Published in the journal npj Computational Materials, the research combines computational predictions of crystal structures with machine learning to hunt for novel materials. The work is theoretical research, meaning that scientists have predicted the new carbon structures but have not yet created them.

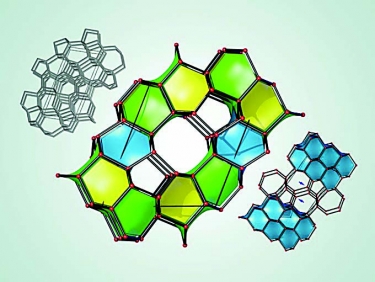

An illustration depicts three of 43 newly predicted superhard carbon structures. Image courtesy of Bob Wilder, University at Buffalo

“We would like to find something harder than a diamond,” said Zurek, who has worked in the field of materials prediction for a decade. “If you could find other materials that are hard, potentially you could make them cheaper. They might also have useful properties that diamonds don’t have. Maybe they will interact differently with heat or electricity, for example.”

In addition to diamond, boron carbide is a superhard material used to cut, polish, drill and grind, as well as for coatings, she said. Several of the theoretical materials are predicted to be nearly as hard as or slightly harder than diamond. Each new variety consists of carbon atoms arranged in a distinct pattern in a crystal lattice.

Zurek said the new superhard materials may have excellent properties and might have technological applications, such as wear- and corrosion-resistant coatings; long-lasting seals for extreme conditions; high-speed dry machining; drills for energy-efficient mining of hard, tough rock formations; and tools for cutting, polishing and grinding. These novel materials may find further importance in defense applications, such as coatings for body armor and tanks.

First, a way must be found to synthesize some of the predicted superhard phases, she said. One method is via high-pressure synthesis. Cold-compressed graphite is an example of how new forms of carbon, some of which are superhard, can be made under pressure and quenched to atmospheric conditions.

“I am currently collaborating with Russell Hemley, who led one of the first groups to make cold-compressed graphite,” Zurek said. “Hemley also has developed a technique to make diamond via chemical vapor deposition.”

Related Glossary Terms

- chemical vapor deposition ( CVD)

chemical vapor deposition ( CVD)

High-temperature (1,000° C or higher), atmosphere-controlled process in which a chemical reaction is induced for the purpose of depositing a coating 2µm to 12µm thick on a tool’s surface. See coated tools; PVD, physical vapor deposition.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- polishing

polishing

Abrasive process that improves surface finish and blends contours. Abrasive particles attached to a flexible backing abrade the workpiece.