Every manufacturer looks for ways to add value for customers and derive value from suppliers. With machine tool spindle repair, end users can gain value by receiving a complete, comprehensive repair that is done quickly and economically.

Spindles are the heart and soul of machine tools and the most precise, heavily stressed components of a machine. Special care therefore must be taken to ensure that spindles are designed and built to provide the required accuracy and longevity. When a spindle degrades, a machine tool either does not hold specified tolerances or does not produce parts at all. In any case, it costs money.

When a spindle goes down, it is natural to want a machine back up and running as soon as possible. Having a spindle down in the middle of a job with a tight delivery is not a good feeling. However, although you need a spindle repaired quickly, it must be repaired correctly. A fast but substandard repair is not much consolation if part tolerances do not hold or a spindle quickly fails again.

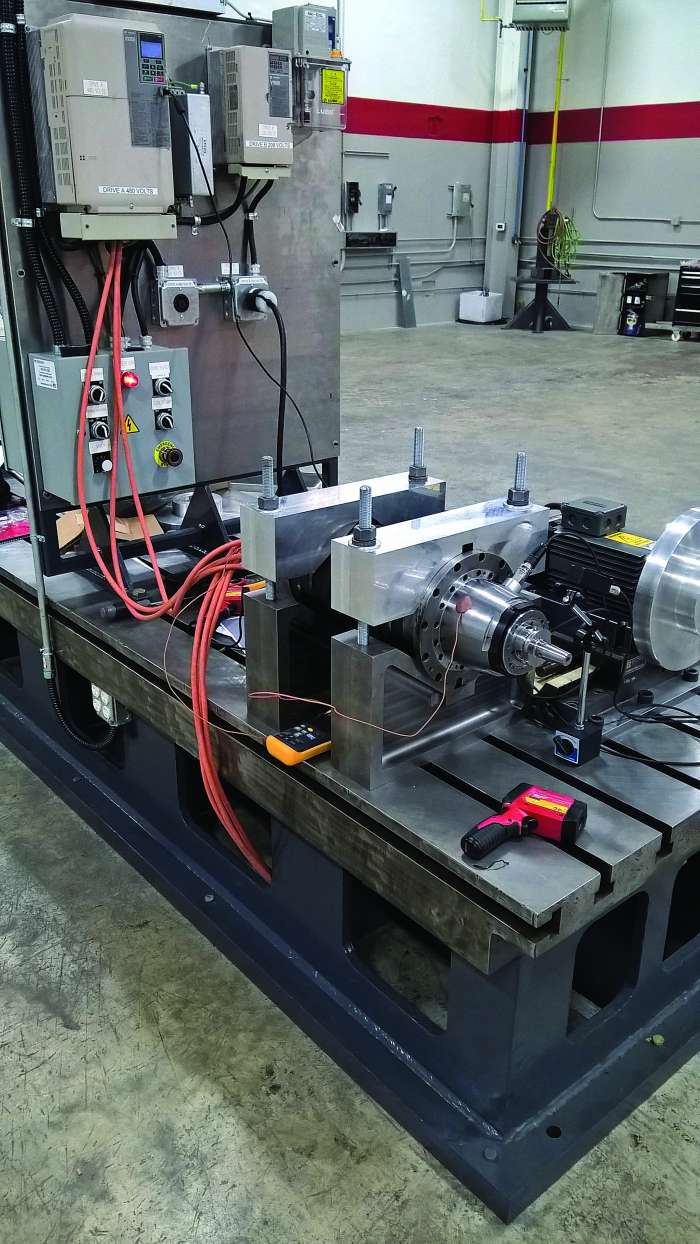

Final runoff is performed on a test stand for a high-speed Kessler spindle. Image courtesy of Advanced Spindle Technology

Trust, but Verify

So how do you know that a spindle will be repaired as quickly as possible without cutting corners or taking shortcuts regarding the quality and completeness of a repair? The answer is transparency. A spindle repair company should provide proper documentation so customers know they are deriving value from spindle repairs.

In most machine tool spindles, there are 250 to 300 individual component and assembly characteristics that impact performance and longevity. For a comprehensive repair, each of these must be checked and evaluated for suitability. Since many tolerance measurements are in microns, components should be absolutely clean and at the proper temperature to accurately inspect them. To accomplish this, a 24-hour turnaround for a proper spindle rebuild is hardly sufficient. It can take that long for individual components to reach the proper temperature for inspection. A basic expedited repair should take three days from receipt of a spindle to shipping it back to a customer.

All these significant characteristics should be documented clearly by a spindle repair company for a customer to see. Photos of spindle components that show conditions and damaged areas are important for the knowledge and understanding of a customer. The cause of spindle failure, including analysis, should be noted so spindle performance or longevity can be assessed for potential improvement. It is often possible to make changes to bearings or sealing systems to enhance spindle performance or durability.

Test and Measurement

After a spindle is reassembled, test bar runouts should be measured and documented. Drawbar pull forces should be set and documented, and any sensors or encoders used should be tested.

The final assembly performance characteristics should be documented during a complete runoff. Documentation should include the spindle’s steady-state operating temperatures, details of the bearings used in the repair and running vibration and balance characteristics. The vibration spectra at each end of the spindle also provide valuable information, which can be used as the baseline for a predictive maintenance program.

If all this sounds like a lot, that is because it is. Proper documentation usually requires about 20 pages. However, that gives enough information so a customer can understand what a suitable spindle assessment and rebuild looks like — specifically, what was wrong with a spindle and what was done to repair it. This level of transparency allows a customer to know that a comprehensive repair was performed and the cost was justified.

If you are accustomed to receiving a single page with an invoice for a spindle repair, evaluate whether you are getting the kind of value you expect and deserve from your spindle repair partner.

Related Glossary Terms

- tolerance

tolerance

Minimum and maximum amount a workpiece dimension is allowed to vary from a set standard and still be acceptable.