A pair of spindle-related advancements may be good news for part manufacturers looking to go beyond what’s possible in conventional machining.

For end users interested in equipping themselves for Industry 4.0, PCI Scemm, St.-Étienne, France, has introduced the e-Spindle, an electro-spindle that uses sensors to monitor cutting processes and actuators to adjust parameters. PCI Scemm developed e-Spindle technology in collaboration with France’s Cetim, the Technical Centre for Mechanical Industry, and France’s Arts et Métiers ParisTech engineering and research graduate school. (PCI Scemm is a partner of Absolute Machine Tools Inc., Lorain, Ohio.)

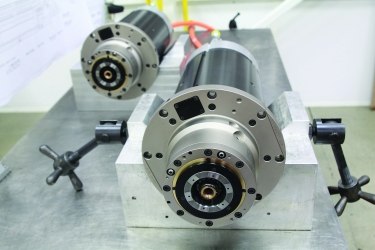

Each spindle in this dual-spindle machining center is able to move in all three directions independently of the other spindle. Image courtesy of PCI Scemm

Vibration sensors inside the e-Spindle allow spindle condition monitoring during machining. Analysis of vibration picked up by the sensors helps users identify problems, such as bearing wear and coolant inside the spindle, said Max Paulet, PCI Scemm’s business development manager for North America.

He said vibration analysis also can determine whether a machining process is reliable. Before a process begins, the acceptable vibration pattern for each cutting tool that will be applied is entered into the machine control. If the vibration pattern for one of the tools goes outside its tolerance limits during machining, the control automatically recognizes the anomaly, which sets off an alarm, notifies an operator or stops the machine.

“The aim is to give machining lines some independence so they can recognize that something is going wrong with the process and not machine bad parts,” Paulet said.

In addition to monitoring vibration and other key process variables in real time, the e-Spindle uses actuation devices to supply up to 5 kVA to tools without physical connections, such as cables, he said. During a machining process, this power can be employed to move the cutting edge of a tool.

Power from the e-Spindle also can generate vibration. This capability may be helpful for applications that involve drilling through difficult-to-cut materials. In these cases, Paulet explained, power is transmitted to the toolholder, causing the drill to vibrate, which breaks up chips and thereby speeds up the process.

“We’ve almost doubled the speed just by generating vibration to break those chips,” he said.

Analysis of data from torque sensors inside the spindle shows whether the drilling process is optimal, Paulet said. If it’s not, the machine automatically can adjust the spindle vibration level to keep the drill moving through the material at the highest possible speed.

The e-Spindle allows process monitoring and cutting-edge motion control. Image courtesy of PCI Scemm

Another recent spindle advancement, which is called twin-spindle technology, is available with a few PCI Scemm machine models. While linked twin-spindle machines on the market offer only z-axisindependence, PCI Scemm’s twin-spindle machines have two fully independent carriages.

“It’s more like having two machines in one,” Paulet said.

With two independent spindles, programming one of the machining zones for a new job doesn’t require the other zone to be reprogrammed.

“You can leave that spindle programmed as it was with a specific cycle and save all the adjustments you’ve made to make good-quality parts,” Paulet said.

He said the benefits of having two spindles that operate independently of each other are apparent to manufacturers of powertrain components. Finishing operations for these components require high spindle accuracy, which he said is hard to achieve for long with conventional twin-spindle machines because any adjustments that are made affect both spindles. With two independent spindles, on the other hand, once adjustments are made to one spindle to achieve the desired accuracy, they won’t be affected by subsequent adjustments to the other spindle.

“This helps people get a reliable process for an extended period of time,” Paulet said.

Related Glossary Terms

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

- tolerance

tolerance

Minimum and maximum amount a workpiece dimension is allowed to vary from a set standard and still be acceptable.

- toolholder

toolholder

Secures a cutting tool during a machining operation. Basic types include block, cartridge, chuck, collet, fixed, modular, quick-change and rotating.