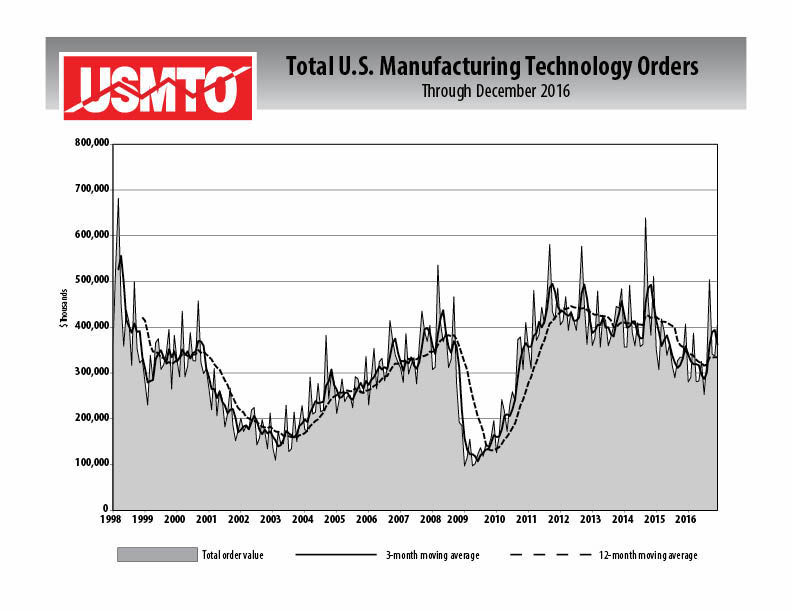

AMT — The Association for Manufacturing Technology released its December 2016 U.S. Manufacturing Technology Orders Report this week, noting that orders finished 2016 down 4 percent compared to 2015. But the report also holds some good news: month over month data showed December orders up a whopping 20.6 percent compared to November.

That data along with other manufacturing economic indicators lead AMT to conclude that "the general manufacturing economy is showing signs of growth."

Among the other economic indicators cited by AMT:

- The Institute for Supply Management's January 2017 PMI reading of 56, which is an indication that U.S. manufacturing expanded for the fifth consecutive month. The PMI, or Purchasing Managers Index, measures new orders, production, employment and supplier deliveries throughout the U.S. manufacturing industry. A reading above 50 percent indicates that the manufacturing economy is generally expanding.

- Growth in capacity utilization and industrial production in December, the most recent month for which data are available.

- Cutting tool consumption and machine-shop spending are up.

"There has been a significant uptick in shipments for cutting tools, the primary consumable in the manufacturing process, and machine shop spending for the month was up 32 percent from November," stated AMT President Douglas K. Woods. "Since large manufacturers will leverage their supply chain’s capital equipment before expanding their own capacity, gains for machine shop investment are promising because they typically mark an overall greater need for capacity, and a broader upturn on the horizon."

Orders for December 2016 totaled $406.72 million, up from November’s $337.24 million. The December monthly order value was the second highest for the year after September’s $503.67 million, which was when orders were registered from IMTS. Total orders for 2016 were valued at $4,013.13 million compared to $4,178.23 million in 2015. USMTO is a reliable leading economic indicator as manufacturing companies invest in capital metalworking equipment to increase capacity and improve productivity.

AMT's full release, with graphs, is here.

Related Glossary Terms

- metalworking

metalworking

Any manufacturing process in which metal is processed or machined such that the workpiece is given a new shape. Broadly defined, the term includes processes such as design and layout, heat-treating, material handling and inspection.