Toolholders

Changing Quick-Change

Though ITI Tooling Co. Inc. introduced the Varia Rapid-Change Tooling System some four years ago, the company's product manager—Lee Hebenstreit—says word of this technology has not yet spread throughout the markets it could help. That's why the company produced a 22-second video showing the Varia tool changing system in action.

Recipe for Quality Toolholders

Justin London, a sales technician and draftsman with Briney Tooling Systems, discussed the proper "Recipe for Quality Toolholders" as one of the Fast Track Seminars hosted at the Cutting Tool Engineering booth during IMTS 2010.

CoroMill Plura with iLock

Sandvik Coromant introduced its new CoroMill Plura with iLock system at the imX event at the Las Vegas Convention Center Sept. 12-14. The new system will be available in 2012.

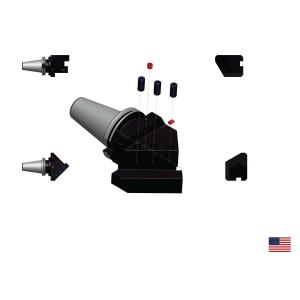

Kennametal quick-change

Kennametal shows a side-by-side comparison of its KM-Micro/Mini quick-change system versus a standard tool in this 2-minute demonstration, courtesy of Kennametal. While the KM-Micro/Mini tool change is complete in just half a minute, the standard tool requires 2 minutes to change, set up and gage the tool.

Tool quickie

In this 2-minute side-by-side comparison, Kennametal shows its KM-Micro/Mini tool being changed in just half a minute versus a standard tool requiring 2 minutes to change, set up and gage.

Bilz Tool introduces ThermoGrip tool clamping system

ThermoGrip is the "new" tool clamping system for automotive, aerospace, medical and die/mold manufacturing. Its high TIR cutting tool precision is said to improve cutting tool performance in tool life and machining accuracy.