Editors' Blogs

As discussed in a recent issue of Cutting Tool Engineering magazine in the feature article “Lean into it,” a little lean manufacturing goes a long way. One factor that tends to trip up people and companies on their way to establishing lean cultures is sustainment. Phillip Canipe, vice president of sales and business development for the Southwest region at Stellar Industrial Supply Inc. in Tacoma, Washington, said 90 percent of companies are reluctant to re-examine processes that already have been inspected and improved.

A blade and knife manufacturer for the lumber industry suggested that it might have to close its plant in Michigan. The largest nail producer in the U.S. has laid off 60 workers and warns that it may be forced to move its factory to Mexico. A California cannery said its profit margins could drop by up to 70 percent over the coming months. A well-known motorcycle manufacturer said it’s shifting some of its production to foreign countries. What is this financial crisis that’s affecting so many manufacturing companies? In each case, the Trump administration’s tariffs on steel and aluminum are said to be the culprit.

Every wonder what it would be like to sell machine tools for living? Rantings of a Machine Tool Salesman by Scott Walker provides a flavor of that wonderland career. Semiretired, Walker is chairman of Mitsui Seiki USA Inc., Franklin Lakes, New Jersey, where he started as vice president of sales in 1991. The company specializes in building heavy metal and mother machine tools.

When it comes to hobbing auto gears, dry machining dominates. “There are no new automotive applications that are being done wet,” said Tom Ware, product manager for gear tools at Star SU Co. LLC, Hoffman Estates, Ill. “There are a few tier suppliers that have not updated to new equipment and are still running some wet applications, but all the major manufacturers have gone dry.”

Zoller Inc. hosted its open house and Innovation Days event June 19-20 at the tool presetting and measuring equipment manufacturer’s new facility in Ann Arbor, Mich.

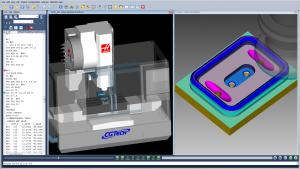

The 54th annual National Leadership and Skills Conference scheduled for June 25-29 in Louisville, Kentucky, is expected to draw more than 6,000 students, with a fraction of them competing to be named the best CNC milling specialist, CNC technician and CNC turning specialist in the nation. “This is a great opportunity for students to see where their skill levels are compared with their peers,” said Steve Arteman, technical support engineer at CGTech Inc., Irvine, California, the developer of Vericut CNC simulation and verification software.

I’ve had a problem recently with our vertical blinds. The damn things keep breaking. Every few weeks, I’ll find a vane lying on the ground after the tab at the top busts loose, sending the 6'-long hunk of plastic flying. I know when it happens because the dog runs and hides under the bed, whining like someone said “veterinarian.”

It’s a rite of passage for any new machinist. You order dial calipers, a few micrometers and a dial indicator or two, and before long you’re wondering where you’re going to stick all this stuff. It’s time to get your first toolbox.

Usually, a grinding process can be improved by simply picking the low-hanging fruit. Grinding wheel manufacturer Meister Abrasives USA Inc., North Kingstown, R.I., recommends trying that approach first by selecting a single variable and significantly changing it.

Once again, the International Manufacturing Technology Show is right around the corner. IMTS 2018 takes place Sept. 10-15 at Chicago's McCormick Place, which is literally just down the road from where I live.

Some people say there is an art to machining. In some cases, there is actual artwork. Machinists Inc. in Seattle, the largest precision machining shop in the Northwest, has made big sculptures since the early 1990s. The first piece was a 17'×13'×3' steel sculpture that hangs in Harborview Medical Center in Seattle, and many more have followed. However, art accounts for only about 1 percent of the manufacturer’s work, said Weld Engineer Steve Pollard, who has been with the company for 30 years.

I received an email from a reader letting me know that he disagreed with my recent article on tapping versus thread milling. In it, I stated, “There’s little chance of successfully thread milling metals much above 45 HRC. And if you’re going to try to tap them, be prepared to duck the flying shrapnel when the tap explodes!” We all make mistakes. So when Tom Fares, president of TNT Custom Equipment in Stow, Ohio, called me out on that section of the article, saying that he routinely taps holes in 45 HRC steel alloy and thread mills into “the low 60s,” I listened to what he had to say.

Seventy years ago when the Society of Carbide Engineers launched the trade magazine that eventually became Cutting Tool Engineering as its official publication, the articles primarily covered carbide cutting tools. After all, the association advertised that those who were engaged in studying, using, supervising the use of or furthering the use of carbides were eligible for membership.

As discussed in the current issue of Cutting Tool Engineering magazine in the feature article “Specialization on tap,” material-specific taps continue to evolve. Sources anticipate increasing specialization of the materials used for taps across industries.

I admit to some bias against school. From about fifth grade on, our educational system and I were rarely on speaking terms. Think oil and water rather than peas and carrots. Needless to say, I left at my earliest opportunity. Aside from that thing with my daughter pulling the fire alarm, my kids were far better students. So when it came time for them to make the big decisions, I kept my opinion to myself and did what most parents do these days: Encourage them to get their college degrees.

BIG KAISER Precision Tooling Inc. held its Breakfast & Learn 2018 open house May 8-10 at its headquarters in Hoffman Estates, Ill. Each day include a technical presentation. On the third day, John Zaya, workholding product manager for BIG KAISER, covered multiple-axis, quick-change workholding systems.

Florence, Ky.-based Mazak Corp. hosted the Midwest Technology + Education Event May 1-3 at its Midwest Regional Headquarters and Technology Center in Schaumburg, Ill. The machine tool builder exhibited and demonstrated an array of equipment, including milling, turning, 5-axis and multitask machines, and nine of the company’s Value Inspired Partners exhibited at the event.

Bob Hudson of New South Whales, Australia, responded to my April 11 blog titled "Assisting manufacturers with augmented reality."

My Jan. 29 blog post, "Simple steps improve shop websites for hiring," received an insightful reply from Gerry Anger, president of Granger Sales Inc.

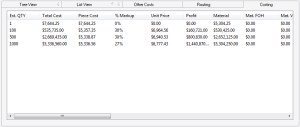

I once worked in the cubicle next to Mike, the shop’s estimating guy. He sat there all day using an electronic pen to trace the outlines of parts on paper drawings. He painstakingly determined the length of each journal, the depth of each hole and the number of cubic inches contained in each milled pocket before feeding that information into the company’s estimating software. That’s all Mike did.