Smarter Setups

Smarter Setups

Tool presetters are helping small shops reduce setup time, minimize scrap, and improve consistency across machines.

In a machine shop, every idle spindle and every miscut part chips away at productivity — and profit. That's why, for many shops, tool presetters have emerged as a quiet revolution in how jobs are set up, tools are managed, and operators are trained. Once dismissed as an unnecessary luxury for high-production environments, presetters are now increasingly viewed as an essential tool — especially for small and mid-size shops trying to do more with less.

According to experts from Lyndex- Nikken Inc., Haimer USA, and BIG DAISHOWA-Americas, the role of the presetter is evolving. "Ten years ago, motorized axes and automated features were reserved for high-end models," said Eric Hartman, Presetter Product Manager at Lyndex-Nikken. "Today, those features are in entry-level benchtop machines."

This shift has broadened accessibility, but U.S. adoption still lags behind Europe, where presetter adoption is estimated at 70% to 80%. Whereas in U.S. shops, presetter adoption is said to be about 30% to 40%.

Resistance and Misconceptions

That gap is due, in part, to the notion that presetters don't help a shop cut chips. "Buying a machine tool is an easy decision because it cuts parts," explained Haimer USA President and CEO Brendt Holden. "A presetter doesn't — but it lets your existing machine tools cut more parts, more efficiently."

Holden speaks from experience. Years ago, he worked in a 15-person job shop where setup involved walking up to a machine and manually touching off each tool while the spindle sat idle. "If I had a presetter back then," he said, "I could've saved 25 minutes per setup."

That 25 minutes becomes significant when you're running dozens of jobs per week. Still, many small shop owners remain skeptical. "They always say, 'We're too small,'" Holden added. "But in reality, the smaller the shop and the more frequent the changeovers, the more value a presetter brings."

Jack Burley, President and COO of BIG DAISHOWA, echoed that sentiment. "Presetters are often misunderstood by small shops. They're seen as a luxury. But when used correctly, they quickly become essential."

The Real Role of a Presetter

According to Burley, presetters act as "master gauges" for the shop. Rather than relying on manual offsets or machine-specific zero points, presetters create a standardized system across all machines. "You reduce the first-part rejects, accelerate setup time, and decrease operator dependence," he said.

There's also a misconception that in-machine probing systems negate the need for presetters. All three experts pushed back on this notion.

BIG DAISHOWA's SPI (Simple Post Interface) enables operators to measure tools, print labels and scan the data directly into their machine tool control.

"Probes are great for edge detection and confirming the cutting tool condition during a cycle," said Holden. "But they can't replace the precision or efficiency of offline presetting. And you need a probe on every machine. One presetter can serve the whole shop."

Hartman agreed: "Any time you're using the spindle on the machine tool to measure your cutting tools — that's time you could be cutting chips."

Overcoming the Growing Pains

Adopting a presetter isn't just about the equipment — it's about changing shop floor behavior. Hartman shared how many shops cling to the practice of prepping tools at the machine, following a familiar routine: program the job, print the setup sheet, then start pulling tools, fixturing, and materials right at the machine. But with a presetter, that process can — and should — change.

"If you already know which tools the job requires from the CAM program," Hartman said, "why wait? You can build a tool crib, measure them offline, and feed that data directly to the machines."

It's not a complex adjustment, but it's a cultural one. "The hardest part isn't learning how to use a presetter," he said. "It's overcoming the resistance to changing any process on the shop floor."

The ROI Equation

So, what's the payoff?

The most obvious return on investment is setup time. Holden estimates that presetters can reduce setup time by up to 70%. By moving tool measurement offline, machines stay cutting while the next job is being prepared.

But Burley suggested shops also look beyond setup time when calculating ROI. "Ask yourself, what is the value of first-part precision?" he said. "That alone can justify the investment."

Other benefits include: Fewer bad parts:With the presetter as your master gauge, first-part quality improves significantly. Burley explained that instead of dialing in offsets on the machine, tools are preset to consistent standards. That consistency prevents the need to scrap early parts during trial cuts.

'Presetters are often misunderstood by small shops. They're seen as a luxury. But when used correctly, they quickly become essential.'

Improved tool longevity: A presetter helps ensure tools are set correctly, which allows tools to run more efficiently and wear more evenly. Additionally, monitoring tool runout helps optimize cutter life and cutting capability preventing scrap or poor finishes.

Holden pointed out that balanced and precisely measured tools run more efficiently and wear more evenly. Combined with proper holders — such as shrink-fit or balanced collet systems — the life of the cutting tool and even the spindle itself is extended.

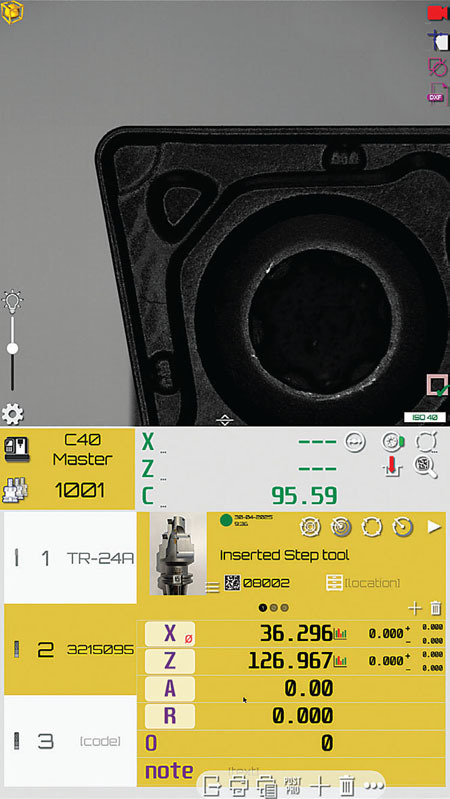

Presetter inspection camera view can be used to check for damaged cutting tool edges. Lyndex-Nikken

Autofocus of the presetters C axis can measure a tool 360° to increase operator efficiency. In this case, a shell mill with 10 inserts was measured. Lyndex-Nikken

Fewer scrapped tools: With tool management software like BIG DAISHOWA's Intelligo, shops can track tool usage, remaining life, and storage locations. "Operators used to throw out inserts just because they didn't know how much life was left," Burley said. "Now we can track that data. If a tool has 50% life left, we don't toss it. We use it."

Cutting Scrap Before It Happens

One of the most overlooked benefits of presetters is visual inspection. Holden noted that modern presetters include cameras or lights that allow operators to inspect tool tips before they go into the machine.

"Chipped inserts, worn tools — these are often caught after a part is ruined," he said. "A presetter lets you catch it before it happens."

Hartman shared the story of a shop that used custom reamers. They began using their presetter exclusively for inspection. "They weren't even using it to post offsets — just to inspect geometry and avoid scrapping expensive parts."

And in many shops, where complex step tools like hydraulic porting reamers are used, presetters are invaluable. "If the distance between features on that tool is even slightly off, it can ruin the part," said Hartman. "Presetters measure those distances to the micron."

Operator Improvement and Training

Beyond boosting efficiency, tool presetters are reshaping how shops train and empower their workforce. At a time when skilled labor is increasingly difficult to find — and keep — anything that shortens the learning curve is a competitive advantage.

"The people who benefit the most from presetters," said Hartman of Lyndex-Nikken, "are often those still using old-school techniques —touching tools off on a block or a piece of paper. We timed it. That method takes about two minutes per tool."

The HAIMER UNO Special Edition is an easy to use entry level presetter for any size shop. Haimer

That adds up. A 30-tool job setup using the paper method can burn an hour or more. "With a presetter," Hartman added, "you can get all 30 tools measured in under 15 minutes. If you're really fast, under 10."

The training process itself is simpler, too. Lyndex includes onboard help videos with each presetter — accessible directly from the user interface. "If I install a presetter on a Friday and train the team, they'll be experts by the end of the day," Hartman said. "But by Monday, they'll forget about 60% — that's just human nature. The videos are a good resource available anytime to help them quickly pick it back up."

These videos are tied to specific buttons and icons. "If an operator forgets what a function does, they can click a flashing icon and watch a quick explainer. It's faster than thumbing through a manual."

Holden, of Haimer USA, underscored this point: "Presetters make production predictable, even when experienced machinists retire or leave. They replace tribal knowledge with a repeatable process."

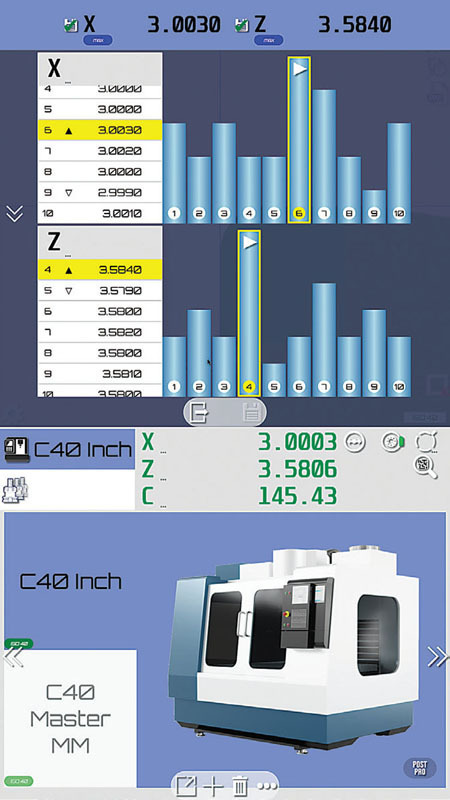

Standardizing Setup Across Machines

Burley, of BIG DAISHOWA, emphasized one of the most transformative benefits of presetters: eliminating the variability between machines.

"Most shops touch off tools on each individual machine. But that approach locks your tooling data to one location. With a presetter, your offsets are generated consistently from a single master gauge," Burley explained. "We encourage shops to stop thinking in terms of each machine having its own Z zero. Instead, let the presetter define the gauge length. That becomes your standard."

Making this transition does require discipline. "Shops get used to their methods," Burley said.

Tips for purchasing a shop's first presetter

For shops that have not yet purchased a presetter, the experts CTE consulted for this report offered the following tips.

1. Define Your Needs

How many machines do you run?

How often do you change over tools?

Do you run custom-ground tools or tight tolerances?

2. Choose a Scalable Entry Model

Start with a benchtop model that's easy to use and modular.

Look for thermal stability and shop-floor durability.

3. Avoid Proprietary Technology

Choose a system that can expand and integrate with multiple software platforms.

Seek assurances that the system you select will easily integrate with other machines you may purchase in the future.

4. Keep It Simple

Even printing basic tool labels with Z-axis offsets can provide immediate time savings.

There's no need to jump into full automation on day one. Start with a simple, repeatable process that works for your team.

'The people who benefit the most from presetters are often those still using old-school techniques — touching tools off on a block or a piece of paper. We timed it. That method takes about two minutes per tool.'

"Convincing them to move to positive offsets and let the presetter be the authority — that's a mindset shift. But once they do, every machine runs the same, every time."

Tool Management and Waste Reduction

Pesetters also lay the foundation for smarter, leaner tool management. Burley shared that tool waste isn't just about breakage — it's about tracking.

"Talk to any shop owner. They'll tell you the same story: 'My guys hide the good tools in their toolboxes. I don't know how many inserts we really have. And half our cutters are sitting unused in a carousel somewhere.' That's money lost."

BIG DAISHOWA's Intelligo software — which can be used with or without a presetter — helps address this chaos. "It's not just a cabinet," Burley said. "You assign tool jobs, label everything, and track movement. You know where a tool is, how many cuts it's made, and how much life is left."

It even helps recapture lost value. "Say you've got a 1-inch carbide endmill with 50% life left. You'd normally toss it. With tracking in place, you reassign it. You don't need to buy a new tool for that job."

Hartman added that modern presetters now integrate with CAM systems and tool vending machines, creating a closed-loop environment. "You get real-time feedback on stock levels, usage rates, and tool wear — all without walking across the shop floor."

The Rise of Combo Machines

Space and budget are always concerns for smaller shops. That's where combo machines — which combine tool presetting and balancing functions — come in.

"Floor space is a big factor," Holden noted. "If you need both functions, having one machine that does both saves space and cost. Plus, you only need one set of adapters."

This also simplifies operations. "Presetters and balancers typically use different spin adapters depending on the taper," Holden explained. "But with a combo machine, you clamp the tool once and handle both tasks. HSK, CAT — doesn't matter. One spindle handles it all for both the balancing and presetting."

According to Holden, combo machines have helped many skeptical shops finally adopt presetting. "They couldn't justify a presetter alone — but when we showed them how balancing would improve spindle life and cut cycle times, they were sold. And then it was, 'Why didn't we get this years ago?'"

A Smarter Path for the Next Generation

Today's manufacturing workforce is undergoing a major generational shift. Many veteran machinists are retiring, and new hires often come in with minimal hands-on experience. That's where presetters offer an unexpected benefit: leveling the playing field.

"You don't need decades of experience to measure tools properly with a presetter," said Holden. "The software guides you, the camera does the work, and the machine tells you if something's wrong."

Chasing offsets manually, observed Burley, is a time-consuming process for experienced and new operators alike. "There's probably nothing more frustrating than setting up a repeating job," he explained, "where you have to redo all the work from scratch each time. You don't have any documentation about the tools you used. You have the program, and you might remember a little bit about how you fixtured it or whatever, but you really don't have a tool list — a jobs list."

BIG DAISHOWA's entry-level SPERONI STP ESSENTIA tool presetting and measuring system provides essential basic functions. BIG DAISHOWA

This UBI tool management system (shown at right) from BIG DAISHOWA features the company's INTELLIGO software, and together these systems provide real-time stock status. BIG DAISHOWA

That's where the value of a presetter becomes evident, he continued. During an initial job setup, Burley said, operators enter a description of all the tools required for that job. That way, the next time the job has to be run, the operator just has to call up the job recorded within the presetter software.

The Bottom Line: Control

Ultimately, tool presetters give shops more control — over their time, their quality and their consistency.

"What you're really buying is process control," said Burley. "You're not just saving setup time. You're setting your shop up to run smarter, waste less and scale with less risk."

Hartman summed it up like this: "Presetters aren't just a convenience. They help improve a shop's bottom line by maximizing uptime, boosting accuracy, ensuring consistency and improving overall machining efficiency — for both mills and lathes."

And once the shop operators begin using a presetter, observed Holden, "they start asking how they ever lived without it."

Supplemental digital content

For a brief video demonstrating presetter technology and access to two online presetter ROI calculators, click or scan the accompanying QR code. Lyndex-Nikken and BIG DAISHOWA each offer free online ROI calculators to help shops estimate the time it will take a presetter to pay for itself in cost savings once it is implemented.

Glossary terms in this article