The creation of a part program for a CNC machine tool usually starts with a part drawing or model that contains the part material, geometry and tolerances. The manufacturing engineer starts with this model and then selects the required cutting tools, designs the fixturing, selects the machining strategy and chooses the toolpaths and machining parameters.

Usually, software assists with the creation of the toolpaths. Canned routines are available to automate much of the labor required for programming common tasks. Pocketing routines exist for many strategies, such as spiral in or spiral out, and other routines exist that favor either climb or conventional milling. Geometry simulation software often verifies that the final geometry is correct and there are no unintended collisions between the tool, holder, fixtures and workpiece.

At this point, the NC program is ready for post-processing. Post-processing is the process by which the NC program is translated into the commands necessary to create the part geometry on a specific machine. Each individual machine has its own piece of software, a “post,” which takes the NC program created by the manufacturing engineer as input and produces the commands expected by the machine tool controller as output. The post is sometimes provided by the machine tool builder, but usually the end user creates the post.

The post is machine-specific because, for example, different machines have the axes arranged in different configurations. Five-axis machines with A and B axes require different commands than machines with A and C axes to achieve the same relative motion between the tool and workpiece. Different machines have different available features (like the ability to execute a loop), expect different header information and differ in their interpretation of nonstandard M and G codes. The post-processor handles all those details.

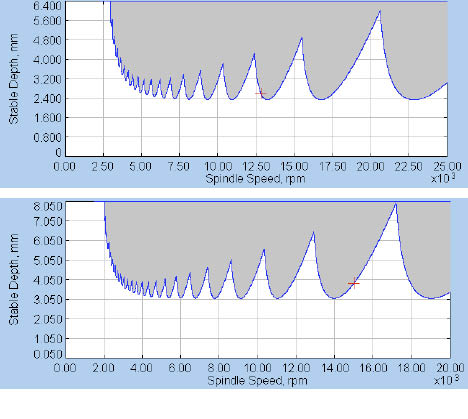

Stability lobe diagrams for the same endmill run in a machine tool with a 25,000-rpm spindle (top) and in a machine tool with a 20,000-rpm spindle (bottom).

In principle, the NC part program can be created based only on the geometry of the desired part and without a specific machine in mind. Later, that same part program can be “posted” for one machine or another, depending on machine availability or cost, for example. If all that mattered was the part geometry, tool and machine, then this strategy should work. If the machine and workpiece were infinitely rigid, and the machine had infinite torque and power, then this strategy should work. But it doesn’t work, or at least it shouldn’t work.

That’s because individual machine tools have unique cutting performance characteristics. Their torque and power vary with the spindle speed. They deflect in response to cutting forces, and the cuts they can make are often limited by the onset of chatter.

The stability lobe diagrams on page 21 are for the same endmill run in two similarly sized CNC milling machines. The vertical axes show axial DOC, and the horizontal axes show spindle speed. The shaded areas are cutting conditions that will lead to undesirable chatter, and the white areas represent smooth, stable machining.

If the manufacturing engineer selected 20,000 rpm for the spindle speed and 4mm for the axial DOC, the top-diagram machine would make the part with no problem, while the other machine would experience severe chatter. If the selected spindle speed was 17,500 rpm, and the axial DOC was 5mm, then the lower-diagram machine would make the part with no problem, while the first machine would experience severe chatter. If the manufacturing engineer selected 17,500 rpm for the spindle speed and 1mm for the axial DOC, then both machines could make the part without chatter, but both machines would be severely underused. In an environment where productivity is a key component of manufacturing competitiveness, selecting cutting conditions that optimize machine performance is a clear advantage.

That means NC programs should be written with a specific machine in mind. For any tool the manufacturing engineer wishes to apply, a stability lobe diagram should be created for that tool in that machine. The engineer should select cutting conditions for that tool and machine that maximize machine productivity, while staying safely inside the stable zone. With a specific machine in mind, the cutting conditions can be chosen respecting the machine-specific limits, including torque and power. Otherwise, if an NC program written without specific machine knowledge is post-processed and it works, that is bad. It almost certainly means the NC program was too conservative. CTE

About the Author: Dr. Scott Smith is a professor at the William States Lee College of Engineering, University of North Carolina at Charlotte, specializing in machine tool structural dynamics. Contact him via e-mail at [email protected].

Related Glossary Terms

- chatter

chatter

Condition of vibration involving the machine, workpiece and cutting tool. Once this condition arises, it is often self-sustaining until the problem is corrected. Chatter can be identified when lines or grooves appear at regular intervals in the workpiece. These lines or grooves are caused by the teeth of the cutter as they vibrate in and out of the workpiece and their spacing depends on the frequency of vibration.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- conventional milling ( up milling)

conventional milling ( up milling)

Cutter rotation is opposite that of the feed at the point of contact. Chips are cut at minimal thickness at the initial engagement of the cutter’s teeth with the workpiece and increase to a maximum thickness at the end of engagement. See climb milling.

- endmill

endmill

Milling cutter held by its shank that cuts on its periphery and, if so configured, on its free end. Takes a variety of shapes (single- and double-end, roughing, ballnose and cup-end) and sizes (stub, medium, long and extra-long). Also comes with differing numbers of flutes.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.