When it comes to a Swiss-style machine tool, a guide bushing distinguishes it from a conventional lathe. The guide bushing either rotates ground bar stock and pushes the workpiece into and out of the cutting tool or, less commonly, remains static as the bar in it spins. This arrangement is effective when producing relatively thin parts with a length-to-diameter ratio of at least 3- or 4-1.

“If you have a long and skinny part, oftentimes there’s no better way to machine that than on a Swiss-style, or sliding-headstock, machine, but that typically involves using ground bar stock and a guide bushing,” said Tyler Economan, technical sales manager for Index Corp. in Noblesville, Indiana. “The stock has to be really straight so it can slide through that guide bushing.”

However, sometimes a guide bushing is not needed or wanted, such as when machining short parts or profiling a part that would not be efficiently turned using a guide bushing. To accommodate both scenarios, Index offers the Traub line of CNC sliding- headstock machines, models TNL12, TNL20 and TNL32, that are convertible from sliding- to fixed-headstock operation.

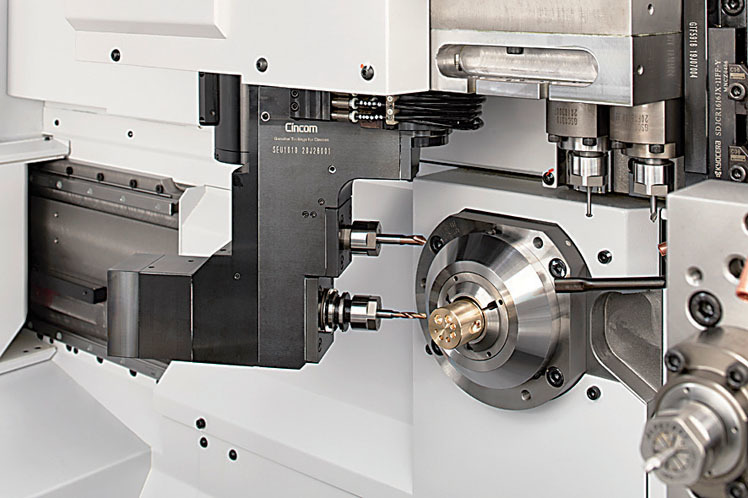

The Cincom L32 series Swiss-style machine can be equipped with a B-axis. Marubeni Citizen-Cincom

The Cincom L32 series Swiss-style machine can be equipped with a B-axis. Marubeni Citizen-Cincom

“If we can switch to fixed-headstock mode, we can use regular stock that’s not ground,” Economan said. “It feeds out to a fixed location.”

He added that a housing either is installed for sliding-headstock mode or removed for fixed-headstock mode, and the conversion process consumes about 10 to 15 minutes.

The medical industry is a major consumer of Swiss-style machines to produce long, skinny implants and parts for surgical devices, but any manufacturer of that small shaft-type or similar parts is an ideal candidate for such a machine, according to Economan. “But what we find is there are a lot of customers that have many of these Swiss-style machines and because they have that machining capacity, they might be making smaller parts that actually don’t require a sliding-headstock machine. The diameter of the machine is going to dictate what parts can go on that machine.”

Index reports that the TNL12 has a 13 mm (0.51") spindle clearance, the TNL20 has a 20 mm (0.79") spindle clearance, and the TNL32 has a 32 mm (1.26") spindle clearance. Rather than purchasing a machine for work that a Swiss shop already has or for a dedicated process that might go away, Economan recommended targeting a more flexible and robust machine that will suit the jobs the shop wants now and down the road. “It always makes sense to have a little bit higher capacity machine than what you need for future growth.”

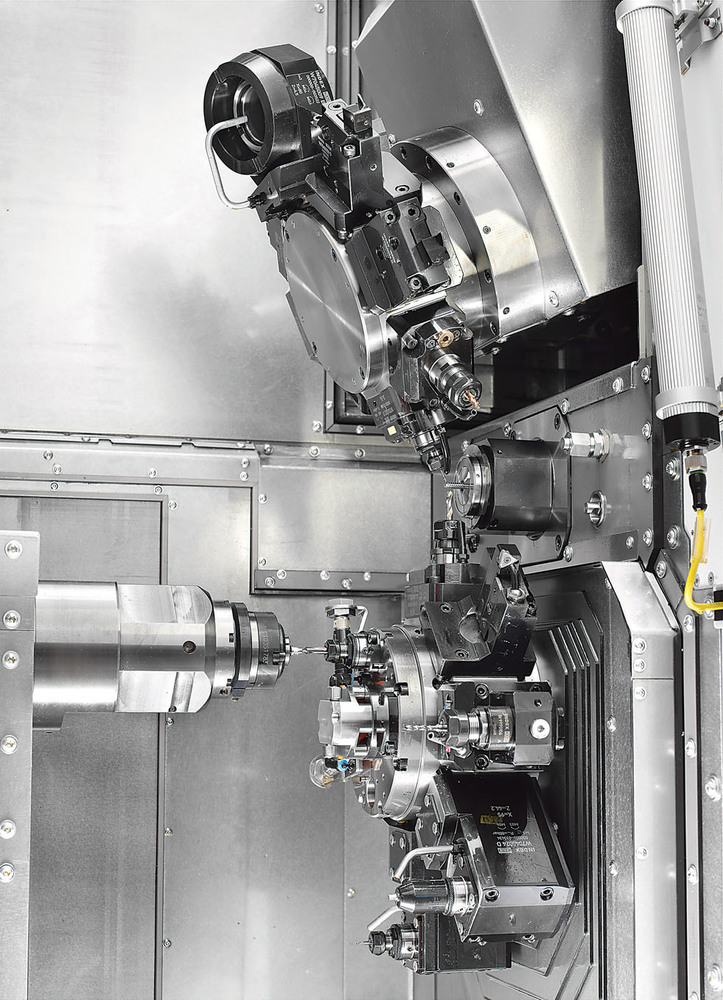

The kinematics of the Traub TNL20 Swiss-style machine allows effective and simultaneous machining with two or three tools. Index

The kinematics of the Traub TNL20 Swiss-style machine allows effective and simultaneous machining with two or three tools. Index

Fix and Slide

Marubeni Citizen-Cincom Inc. is another builder of Swiss-type, or sliding-headstock, CNC automatic lathes that can be used with or without the easily mounted and removed guide bushing. Ray Navarro, service and application manager for the Allendale, New Jersey- based builder, estimates that after a little practice an end user will changeover a machine in about 10 minutes. In addition, a setting must be switched in the machine structure page to change the stroke of the headstock. “The machine is so smart that once you flick that switch, the parameters and numbers change by themselves.

He explained that after the guide bushing is removed, the Cincom machine still has a sliding headstock. Without a guide bushing, the Swiss-style machine is used like a conventional lathe for machining short remnants up to 50.8 mm (2") without the need for pricey ground bar stock. “Without the guide bushing, you’re not moving the part at all, so the part is always in one chuck, and you will turn and mill everything in one step.”

In contrast, Navarro noted that the guide bushing allows for machining parts longer than 152.4 mm (6") using ground stock as long as users segment the part into sections. “If you attempt to do it one shot, you’re going to fall out of the guide bushing. You don’t have support. That’s the biggest thing here.”

Automation continues to make inroads into an array of machining tasks to enhance productivity while helping to overcome the ever-present skills gap, but Swiss-style machines have long been automated with the use of a bar feeder, Navarro said. “On the loader, depending on the size of the bar, you can put multiple 12-ft. bars, and that machine can be run alone the whole day, even the whole night lights out. That’s actually automated. Just put a bar in and you get a part fully finished.”

An automatic toolchanger is also a type of automation and the Cincom Model L20E-3M12B5 has the “smallest ATC machine in the world,” according to Navarro. “We have a sliding headstock machine but we integrated an automatic tool change so you have a carousel with 12 tools that you can put there and act like a milling machine.”

He added that the company integrates robots for specific processes.

To automate a Swiss-style machine, Index offers the optional iXcenter robot cell, Economan said. The company reports that the robot cell is docked to the machine and can be moved to the right during the setup process, allowing unobstructed access to the work area. During production, the iXcenter is fixed in front of the machine’s work area. The robot then accesses the work area via the sliding guard of the machine, which opens automatically behind the robot cell.

Nonetheless, because most work performed on Traub sliding-headstock machines uses 3.66 m (12') bar stock, he added that automation is already in place. “Automation is certainly something we can add to the machines and is something we’re seeing more and more of, but I still think the simplest form of automation is to machine with a bar loader.”

Swiss Precision

When it comes to supplying tooling for Swiss-style machining applications, such as guide bushings, live tools and various collets, Platinum Tooling Technologies Inc. is well established. The supplier of precision machine tool accessories added to its line of Swiss tools last year with the introduction of Dunner guide bushings, said Preben Hansen, owner of the Prospect Heights, Illinois, company. Dunner AG has produced guide bushings at its factory in Moutier, Switzerland, since 1935.

After visiting Dunner and examining its guide bushings, Hansen said the offering was a good match for Platinum Tooling and decided to move forward. “It looked like something not everybody and their brother sells. It’s a unique product, there’s not a lot of competition and it is high-end, which I like because everything we sell is high-end.”

The bushing inserts are made of either bronze, Titane/Meehanite- aged cast iron or NewSurf ceramic. The choice of guide bushing material depends on the workpiece material, Hansen explained. Although most bushings are made of carbide, which Platinum Tooling offers in its Technicrafts line, some materials can rub off on the carbide and become scored, such as titanium, nickel-base superalloys and platinum. Because cast iron is relatively soft, it will not negatively impact a workpiece and “works for everything,” but wears quickly. He added that ceramic, the hardest of the three, lasts the longest.

Swiss shops that machine different metals typically have guide bushings made of different materials, he noted.

In addition, the Dunner guide bushings offer three levels of precision: standard accuracy of 15 μm (0.00059") or less, ultraprecision accuracy of 5 μm (0.00020") or less and ultimate ultraprecision accuracy of 2 μm (0.00008"). Hansen said the standard and ultraprecision are the most popular, with more customers gravitating toward ultraprecision.

He added that only a select number of customers, such as those making high-end medical parts or mission-critical aerospace components, are in the market for ultimate accuracy. “It’s expensive, it takes a long time to get it, but if you want it, you want it. Where there is no room for error, it doesn’t matter what it costs.”

To prevent contamination from chips and coolant getting pushed into the guide bushing, Hansen recommended using some silicone sealant. Otherwise, contamination can score the material or prevent proper clamping. Nonetheless, sealant is optional and may not be necessary for some applications.

A selection of Dunner guide bushings from Platinum Tooling. Platinum Tooling Technologies

A selection of Dunner guide bushings from Platinum Tooling. Platinum Tooling Technologies

The ceramic bushing is only available in a round profile, but square and hex profiles are frequently requested, and customs can be ordered, Hansen said. “We can do pretty much any shape that fits within the space of that collet.”

Generally, ground bar stock is not needed when Swiss-style machining a non-round profile, he noted.

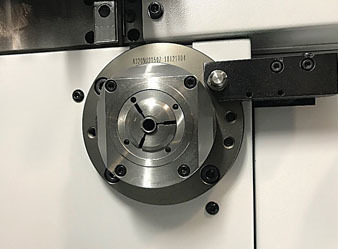

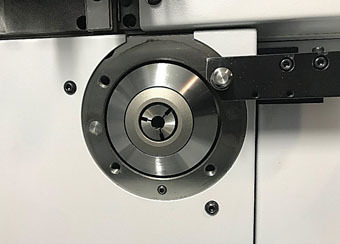

A Marubeni Citizen-Cincom Swiss-style machine with a guide bushing (top) and without one. Marubeni Citizen-Cincom:

A Marubeni Citizen-Cincom Swiss-style machine with a guide bushing (top) and without one. Marubeni Citizen-Cincom:

A Marubeni Citizen-Cincom Swiss-style machine with a guide bushing (top) and without one. Marubeni Citizen-Cincom:

A Marubeni Citizen-Cincom Swiss-style machine with a guide bushing (top) and without one. Marubeni Citizen-Cincom:

An Air Solution

Another way to eliminate the need for ground bar stock is the DunnAir adaptive guide bushing (AGB) system, which replaces the original guide bushing supplied by the machine tool builder, Dunner reports. A non-ground bar might not be consistent in size from one end to the other, and a conventional rigid bushing might bind the bar or allow it to flop around if it’s too loose, Hansen said, adding that the AGB system accounts for up to a 0.508 mm (0.020") difference in the diameter. “The system allows for great flexibility in the size of the material and compensates for material fluctuations.”

The programmable CNC system can also clamp down on a bar, so it does not move, he said. Nonetheless, it’s not for every Swiss-style customer. “An adaptive guide bushing system is a very specialized product for pretty special applications.”

When the system is suitable, the payback can be quick, Hansen added. “Moving to unground stock can more than pay for the DunnAir system in less than a year.”

Marubeni Citizen-Cincom also offers an adaptive guide bushing that is used in place of standard guide bushing units and can utilize non-ground material, Navarro noted. Its AGB uses a “double taper” bushing, which will always close parallel, the company reports. In addition, constant air pressure is applied, which allows the bushing to compensate for bar deviations up to 0.203 mm (0.008") in diameter. The air pressure setting is variable and can be changed as required for each specific job.

A major advantage is eliminating variations in guide bushing adjustment from operator to operator. Once the AGB is set, no adjustment is needed until the user changes to a different bar diameter. The problem of machining gummy materials, such as stainless steel, will also be improved.

Regardless of their tooling needs, Hansen said he has a positive outlook for Swiss-style machining, especially as the medical sector continues to demand increasingly large quantities of single-use products. “Most customers, if they’re in the business of using Swiss machines, they buy 10 or 20 or 30 machines, and then we have customers that have over 100 Swiss machines in one plant.”

The DunnAir adaptive guide bushing system is designed to replace the original guide bushing supplied by the machine builder. Platinum Tooling Technologies

The DunnAir adaptive guide bushing system is designed to replace the original guide bushing supplied by the machine builder. Platinum Tooling Technologies

When a Swiss shop has a large quantity of sliding-headstock machines, Economan wondered whether it has the floor space and personnel to keep adding more Swiss machines to meet growing demand. Depending on the complexity of its parts, the shop might need to find a more productive, less space-consuming option. “If we can find a way to machine the part on a six- or eight-spindle machine, then you’re talking four to six Swiss-style machines versus one Index multi-spindle machine, and that floor space reduction starts to be really sizeable.”

Contact Details

Contact Details

Contact Details

Related Glossary Terms

- automatic toolchanger

automatic toolchanger

Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restores the used tool to the magazine and selects and withdraws the next desired tool from the storage magazine. The changer is controlled by a set of prerecorded/predetermined instructions associated with the part(s) to be produced.

- bushing

bushing

Cylindrical sleeve, typically made from high-grade tool steel, inserted into a jig fixture to guide cutting tools. There are three main types: renewable, used in liners that in turn are installed in the jig; press-fit, installed directly in the jig for short production runs; and liner (or master), installed permanently in a jig to receive renewable bushing.

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

- clearance

clearance

Space provided behind a tool’s land or relief to prevent rubbing and subsequent premature deterioration of the tool. See land; relief.

- collet

collet

Flexible-sided device that secures a tool or workpiece. Similar in function to a chuck, but can accommodate only a narrow size range. Typically provides greater gripping force and precision than a chuck. See chuck.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- lathe

lathe

Turning machine capable of sawing, milling, grinding, gear-cutting, drilling, reaming, boring, threading, facing, chamfering, grooving, knurling, spinning, parting, necking, taper-cutting, and cam- and eccentric-cutting, as well as step- and straight-turning. Comes in a variety of forms, ranging from manual to semiautomatic to fully automatic, with major types being engine lathes, turning and contouring lathes, turret lathes and numerical-control lathes. The engine lathe consists of a headstock and spindle, tailstock, bed, carriage (complete with apron) and cross slides. Features include gear- (speed) and feed-selector levers, toolpost, compound rest, lead screw and reversing lead screw, threading dial and rapid-traverse lever. Special lathe types include through-the-spindle, camshaft and crankshaft, brake drum and rotor, spinning and gun-barrel machines. Toolroom and bench lathes are used for precision work; the former for tool-and-die work and similar tasks, the latter for small workpieces (instruments, watches), normally without a power feed. Models are typically designated according to their “swing,” or the largest-diameter workpiece that can be rotated; bed length, or the distance between centers; and horsepower generated. See turning machine.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- milling machine ( mill)2

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- parallel

parallel

Strip or block of precision-ground stock used to elevate a workpiece, while keeping it parallel to the worktable, to prevent cutter/table contact.

- profiling

profiling

Machining vertical edges of workpieces having irregular contours; normally performed with an endmill in a vertical spindle on a milling machine or with a profiler, following a pattern. See mill, milling machine.

- superalloys

superalloys

Tough, difficult-to-machine alloys; includes Hastelloy, Inconel and Monel. Many are nickel-base metals.

- toolchanger

toolchanger

Carriage or drum attached to a machining center that holds tools until needed; when a tool is needed, the toolchanger inserts the tool into the machine spindle. See automatic toolchanger.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

- web

web

On a rotating tool, the portion of the tool body that joins the lands. Web is thicker at the shank end, relative to the point end, providing maximum torsional strength.

Contributors

Index Corp.

317-770-6300

www.index-group.com

Marubeni Citizen-Cincom Inc.

201-818-0100

www.marucit.com

Platinum Tooling Technologies Inc.

847-749-0633

www.platinumtooling.com