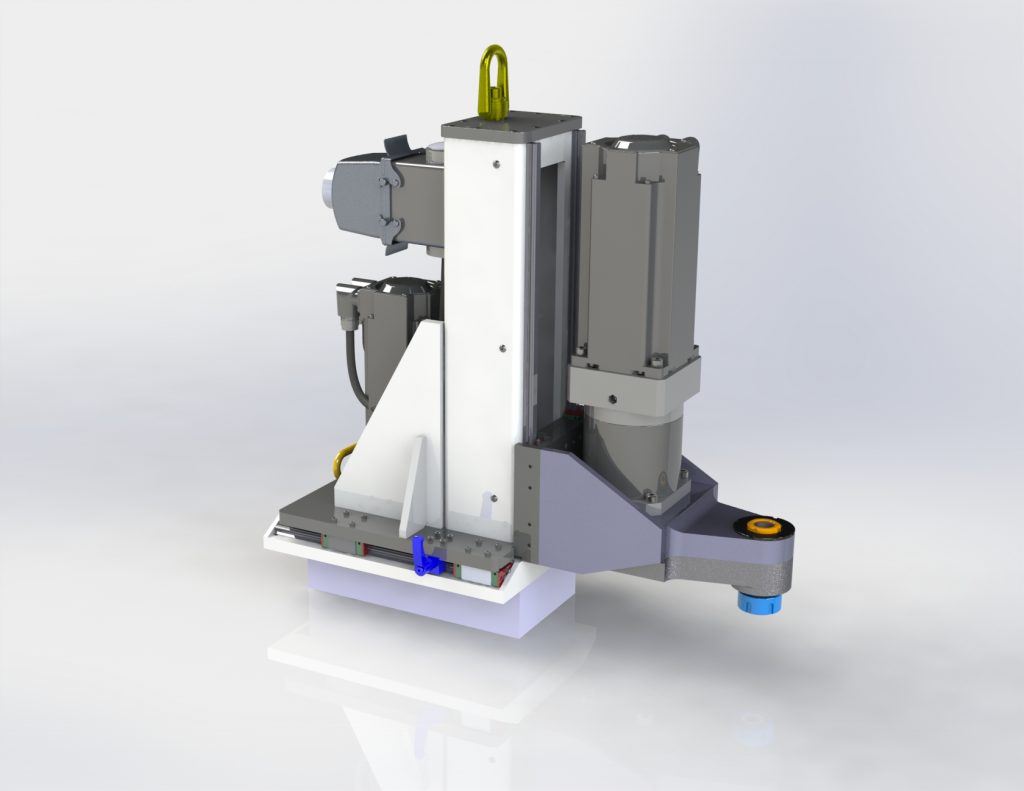

Z-Mag DTM Portable CNC Drill and Tap Machine

Z-Mag DTM Portable CNC Drill and Tap Machine

The unit accommodates different height applications with an available 13 inches of stroke, 1,300 lbf. of thrust and spindle speeds of up to 3,000. Using an HSK style spindle adapter, operators can use a variety of HSK tool holders. The sturdy cast iron frame, linear rail system, and precision ball-screw feed system provide a solid foundation for any application, from light roughing to finishing.

Zagar Inc. introduces its Z-Mag DTM™ portable CNC drill and tap machine for remote holemaking operations. The innovation is geared toward industries such as ship building, bridge construction, railroad and several others where metal removal has to be done on location due to structures that are permanently installed or too large to move. Any needed machining - like modifications, retrofitting or for final assembly needs - must be done remotely.

To serve customers with these permanently affixed requirements, Zagar engineered a unique solution that uses an electromagnetic base with 5,000 lbs. of hold-down force, allowing users to bring precision machining to the job site. Z-Mag DTM can be used on any type of ferrous steel for drilling, tapping, reaming and even combination tooling with programmable feeds, speeds, dwells, and peck cycles. Once in position, the operator can safely and ergonomically operate the unit without the need to manually feed by hand.

The unit accommodates different height applications with an available 13 inches of stroke, 1,300 lbf. of thrust and spindle speeds of up to 3,000. Using an HSK style spindle adapter, operators can use a variety of HSK tool holders. The sturdy cast iron frame, linear rail system, and precision ball-screw feed system provide a solid foundation for any application, from light roughing to finishing. With the use of the handheld HMI (Human Machine Interface), the operator can control the unit with touch screen controls and has the capability to program and run all operations. The unit has a servo feed motor for consistent feed rates and precise hole depths. The hold-in-place solution is well suited for carbide cutting tools.