MILLHOG Dictator Welding End Prep Tool

MILLHOG Dictator Welding End Prep Tool

An upgraded welding end prep tool for machining high temperature, high pressure pipe used on severe-duty offshore piping systems and shale pumping stations is being introduced by ESCO Tool.

An upgraded welding end prep tool for machining high temperature, high pressure pipe used on severe-duty offshore piping systems and shale pumping stations is being introduced by ESCO Tool.

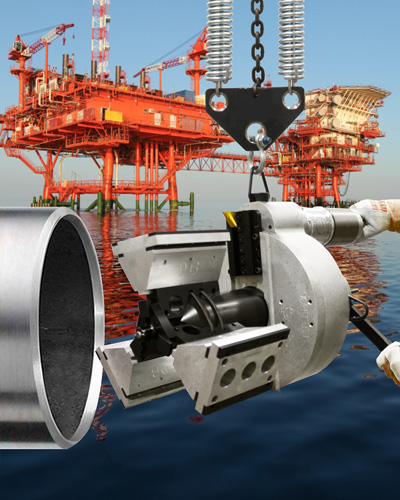

The MILLHOG Dictator Welding End Prep Tool is an I.D. clamping pipe milling machine designed for dry-cutting high-temperature, high-pressure pipe from 4.5" I.D. to 18" O.D. Ideally suited for stainless steel and super duplex piping systems, this tool features a new 3 HP air motor designed for high performance in environments that have dirty air and high moisture content.

Easy to clean and maintain the air motor by just removing one screw to access the rotor & vane assembly, instead of removing the motor from the tool, the MILLHOG Dictator Welding End Prep Tool develops 4,100 ft.-lbs. of torque at the cutter blade and pulls a continuous thick chip without cutting oils. Blades are TiN coated and dissipate heat away from the pipe's surface.

The MILLHOG Dictator Welding End Prep Tool is priced from $21,995.00 and is available for rent from $850.00 per week, depending upon location.