Machinist Calc Pro Machining Calculator for Windows

Machinist Calc Pro Machining Calculator for Windows

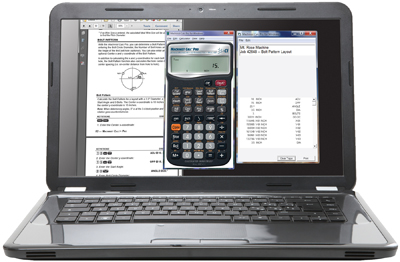

Calculated Industries, maker of the Machinist Calc Pro handheld calculator, has introduced a Windows-compatible software version of its machining math tool.

Calculated Industries, maker of the Machinist Calc Pro handheld calculator, has introduced a Windows-compatible software version of its machining math tool.

Machinist Calc Pro for Windows is an easy-to-use program that lets machining pros use advanced machining math calculations and reference tools without leaving their estimating, scheduling, CAD/CAM, CNC or other machining programs. Precise machining outputs for tasks like bolt pattern layouts can be printed instantly or pasted into spreadsheets, plans or instructions. Machinist Calc Pro for Windows has more complete Thread data than the Machinery's Handbook, including step-saving Thread and Drill Size chart look-ups, speeds and feeds, right triangle solutions, trigonometric functions and much more. The software is compatible with Microsoft Windows XP, Vista, 7 and 8 operating systems.

Dedicated functions include:

Built-in Drill and Thread Size Tables

Drill Point Cut Depth solutions

Cutting Speed, Spindle Speed (RPM)

Feed Rate, Cutting Feed, Feed per Tooth (Chip Load)

Bolt Pattern hole layouts

Advanced Bolt Pattern hole layouts with center X, Y coordinate

Right triangle math

Trigonometric solutions

Wire Sizes and 3-Wire measurements

Machinist Calc Pro for Windows is available at major machining supply dealerships and from Calculated Industries at www.calculated.com. The software sells for $39.95 and comes with two licenses, so machinists can use it in the shop or at home.