Contact Details

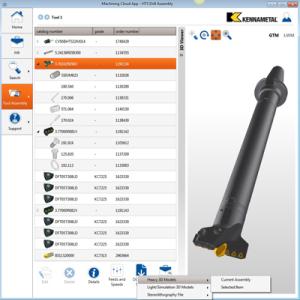

Kennametal announced its latest innovation in high-velocity aluminum roughing, the KOR 5 solid-carbide endmill. With this 5-flute endmill table feed rates increase up to 66% compared to commonly used 3-flute tools—redefining productivity for aircraft manufacturers and their suppliers.

KOR 5 is aimed at removing large amounts of metal and getting it away from the work zone as quickly as possible:

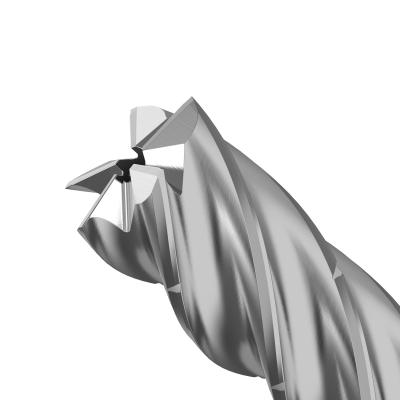

- Tapered core, variable pitch design, and 35° helix – eliminates chatter and tool deflection

- Coolant through the tool - flushes chips away while reducing heat.

- Unique chip splitter pattern - designed to break up long chips, eliminating re-cutting, but still contributes to high surface qualities.

The tool has the potential to become the new standard for machines utilizing CAD/CAM toolpaths.

KOR 5 has more active contact points versus a 2-flute or 3-flute endmill because it is a 5-flute endmill, which creates improved stability and eliminates chatter on even the heaviest cuts.

Applying the tool with low radial engagement, but high depth of cut results in much higher metal-removal rates than traditional methods.

And to assure predictable, no pull-out performance at maximum feed rates, the KOR 5 is available with Safe-Lock shanks.

“Slotting, deep pocketing, dynamic milling—whatever your aluminum application, KOR 5 can do it faster,” said Thilo Mueller, manager for solid-carbide endmilling.

Related Glossary Terms

- chatter

chatter

Condition of vibration involving the machine, workpiece and cutting tool. Once this condition arises, it is often self-sustaining until the problem is corrected. Chatter can be identified when lines or grooves appear at regular intervals in the workpiece. These lines or grooves are caused by the teeth of the cutter as they vibrate in and out of the workpiece and their spacing depends on the frequency of vibration.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- depth of cut

depth of cut

Distance between the bottom of the cut and the uncut surface of the workpiece, measured in a direction at right angles to the machined surface of the workpiece.

- endmill

endmill

Milling cutter held by its shank that cuts on its periphery and, if so configured, on its free end. Takes a variety of shapes (single- and double-end, roughing, ballnose and cup-end) and sizes (stub, medium, long and extra-long). Also comes with differing numbers of flutes.

- endmilling

endmilling

Operation in which the cutter is mounted on the machine’s spindle rather than on an arbor. Commonly associated with facing operations on a milling machine.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- pitch

pitch

1. On a saw blade, the number of teeth per inch. 2. In threading, the number of threads per inch.