Intelli-MAX 18

Intelli-MAX 18

To meet the growing trend of manufacturers processing 3D components on abrasive waterjet machines, OMAX Corp. developed the latest version of its Intelli-MAX Software Suite.

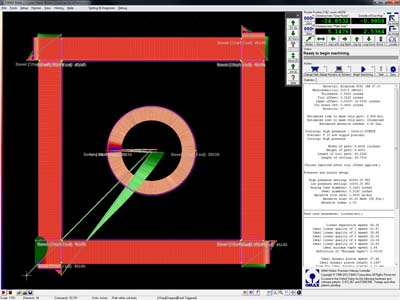

To meet the growing trend of manufacturers processing 3D components on abrasive waterjet machines, OMAX Corp. developed the latest version of its Intelli-MAX Software Suite. The new Intelli-MAX 18 provides programming power and solutions together with functions and features that deliver increased compatibility, expandability and customizability for a wide variety of operations, including 3D part processing.

Intelli-MAX 18 supports up to six axes of coordinated motion – X,Y,Z linear, two tilt and one rotary. With the enhanced functionality, manufacturers can quickly and easily program and cut 3D patterns in a multitude of applications, from the peripheries of tubes and pipes and fitting operations to prep cuts and bevels.

To ensure manufacturers can continue to use their existing CAM systems, Intelli-MAX 18 provides compatibility for more than two dozen third-party CAM systems, including Mastercam, CATIA, SURFCAM and Edgecam. In addition to its ever-increasing portfolio of third-party CAM systems, Intelli-MAX 18 allows for over four dozen file format import options such as Adobe Illustrator, DXF, DWG, SVG and PDF.

New programming features of the Intelli-MAX 18 also expand the capabilities of an OMAX JetMachining Center in terms of cutting various parametric shapes. Supplied parametric shapes within the software eliminate programming redundancy and simplify production, as well as provide the capability to create shapes that were previously impossible or extremely difficult to generate. The latest software also features the new Intelli-VISOR System Monitoring Package that allows users to customize machine monitoring. They can select which aspects of the machine are monitored and specify the action the machine will initiate if a situation occurs.

Another new function of Intelli-MAX 18 is one that allows users to insert, at any point in a toolpath, special commands designated as command numbers representing command strings. This feature is especially beneficial when programming complex commands such as wrapping an existing 2D path/pattern around a 3D part such as tube or pipe.

The new software, which is free to all existing OMAX JetMachining Center owners, is backed by OMAX's support. By continuously adding and updating its help screens, users have access to over 2,000 pages worth of the latest tutorials, troubleshooting guides, and tips and tricks directly at the control.