High-pressure coolant system

High-pressure coolant system

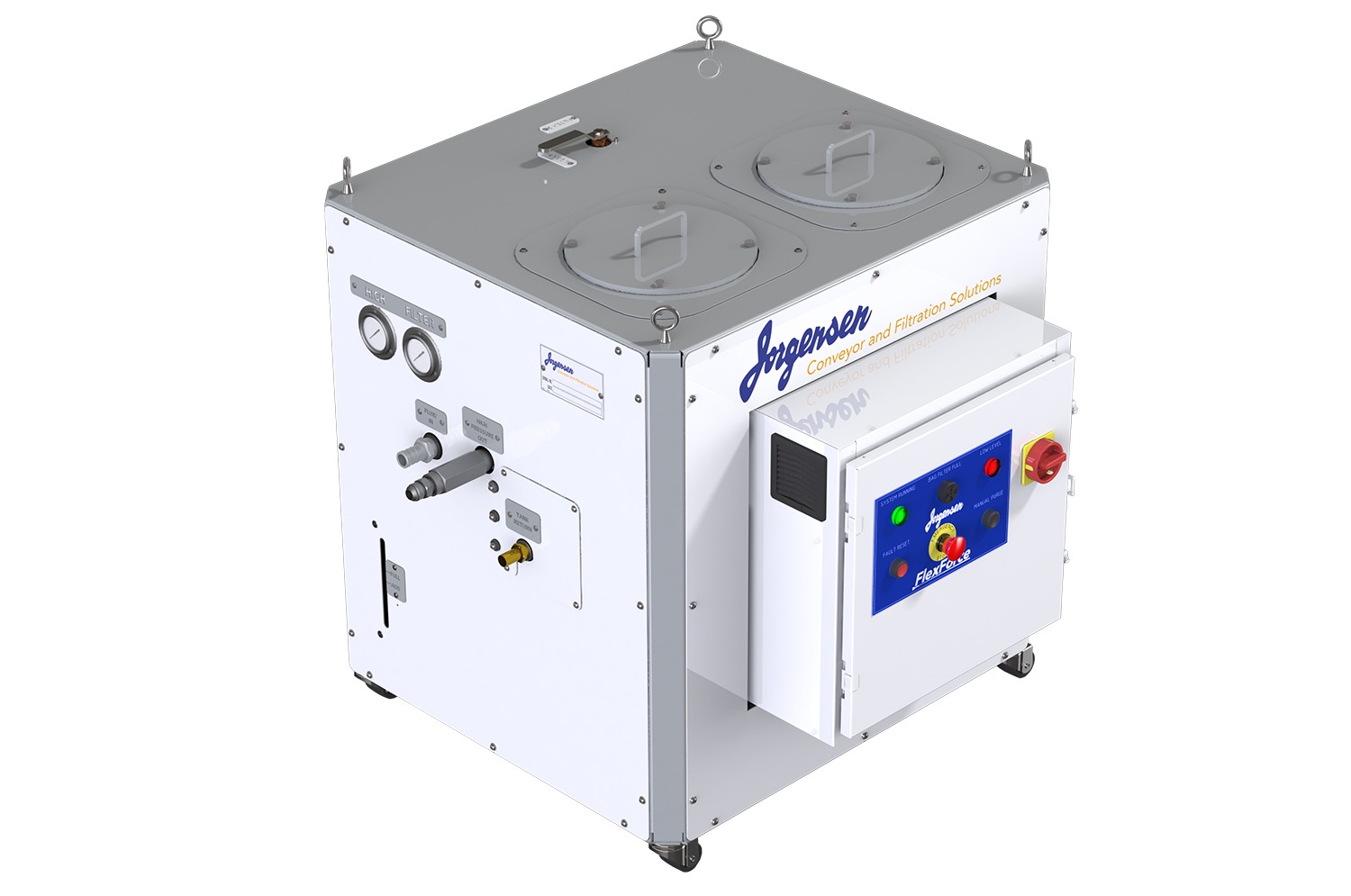

The Jorgensen FlexForce is a high-pressure coolant system for machine tools needing coolant supplied at 500-1000 PSIG for through-spindle coolant (TSC), available with a single or duplex bag filter and a chiller option. The system targets coolant directly at the cutting zone by breaking through the heat-generated vapor barrier created at the cutting tool and workpiece interface. TSC systems also offer better chip evacuation and more consistent temperature control for faster machine feeds and speeds.

The Jorgensen FlexForce is a high-pressure coolant system for machine tools needing coolant supplied at 500-1000 PSIG for through-spindle coolant (TSC), available with a single or duplex bag filter and a chiller option. The system targets coolant directly at the cutting zone by breaking through the heat-generated vapor barrier created at the cutting tool and workpiece interface. TSC systems also offer better chip evacuation and more consistent temperature control for faster machine feeds and speeds.

The FlexForce high-pressure pump sends pressurized coolant through the machine spindle and directly to the cutting point. As a result, machines equipped with TSC coolant systems and FlexForce high pressure see better chip evacuation

FlexForce features an onboard coolant reservoir, a premium, diaphragm pump, small footprint, maintenance-friendly design and provides safe and efficient operation while easily integrating into existing coolant systems. For unique applications requiring specifications beyond the standard 500 or 1,000 PSI models, Jorgensen offers custom-engineered FlexForce units or complete coolant filtration systems

EcoFilter 80

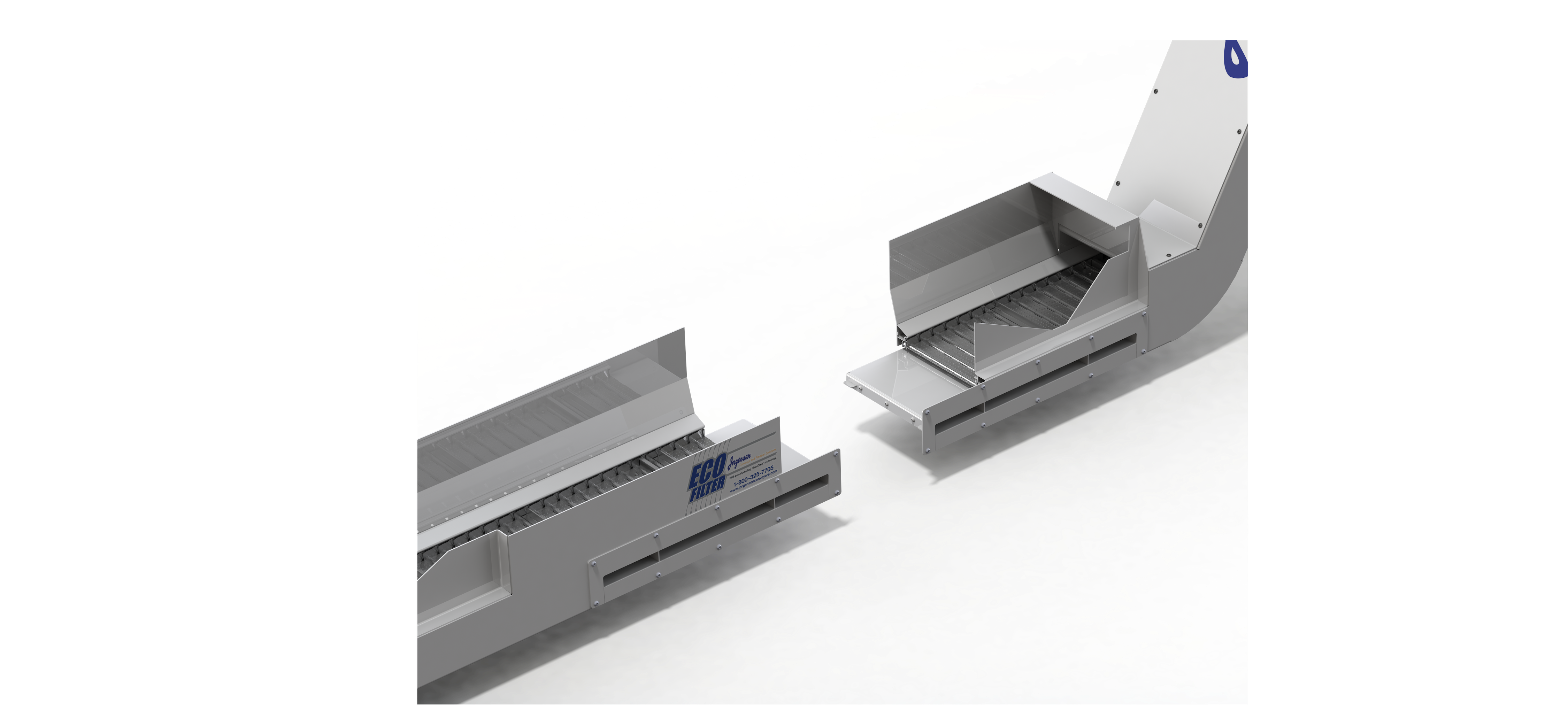

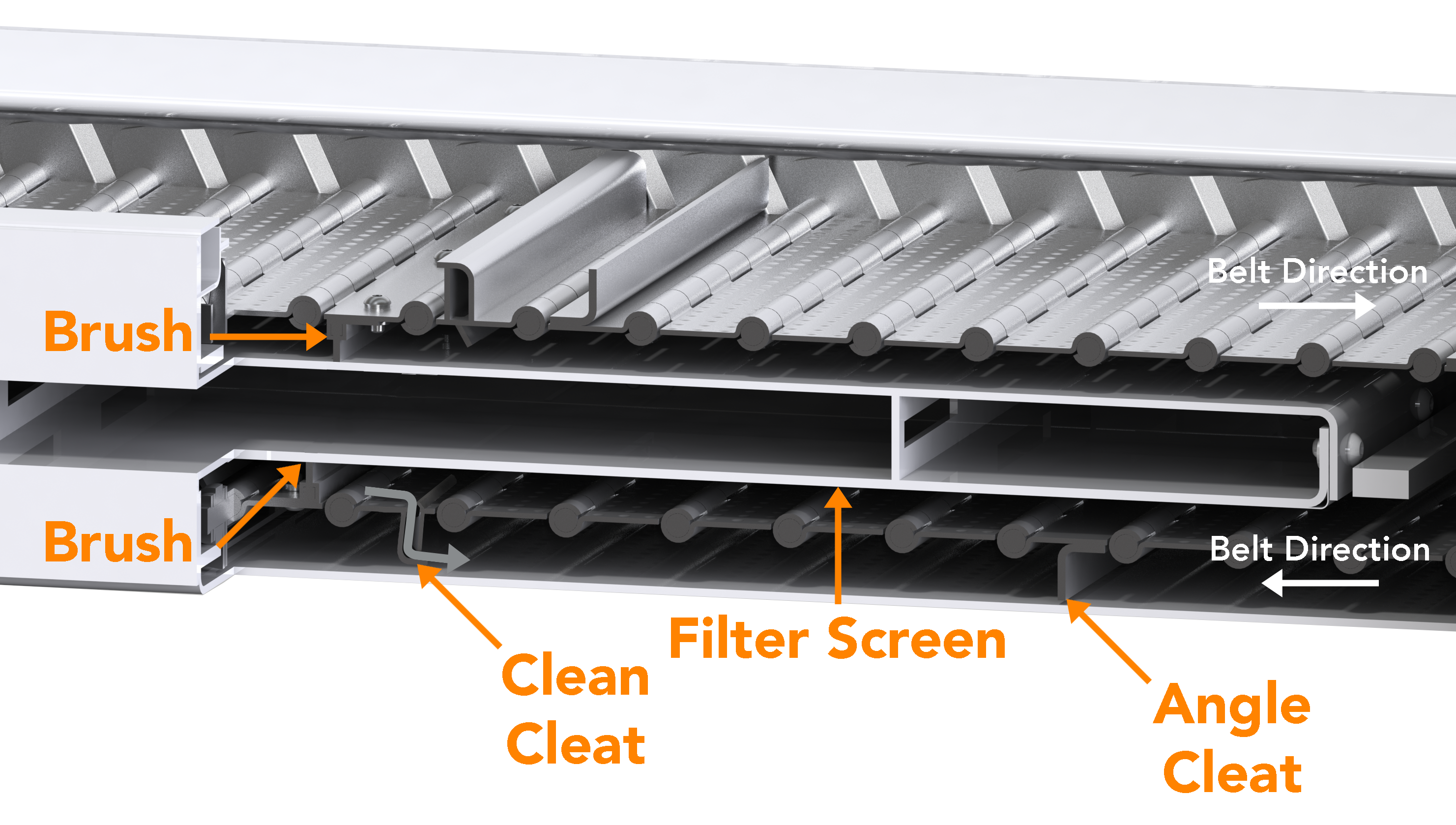

With the capability to efficiently filter fine chips to 80-micron nominal, Jorgensen's EcoFilter 80 is the first third party tested and approved economical non-drum style conveyor below 100-micron filtration. The conveyor simultaneously filters coolant while removing larger chips on a hinged steel belt. Used coolant carries fine chips between the belt runs to a flow-through EcoFilter cell where they are separated from the coolant.

With the capability to efficiently filter fine chips to 80-micron nominal, Jorgensen's EcoFilter 80 is the first third party tested and approved economical non-drum style conveyor below 100-micron filtration. The conveyor simultaneously filters coolant while removing larger chips on a hinged steel belt. Used coolant carries fine chips between the belt runs to a flow-through EcoFilter cell where they are separated from the coolant.

Clean coolant is then discharged to the coolant tank while small metal fines are brushed from the filter screen and flow to the bottom of the conveyor. From there, they are picked up by the belt cleats and discharged. By dramatically reducing the number of chips migrating to a machine tool coolant tank, EcoFilter 80 greatly decreases downtime for tank cleaning and maintenance. As a result, users see improved pump, tooling and coolant life for less waste and better part surface finishes.