CAMWorks Barrel Tool Support

CAMWorks Barrel Tool Support

Barrel tool support was added in direct response to CAMWorks customer feedback and is beneficial for mold makers and manufacturers of complex parts in industries such as automotive and aerospace. As demand increases for lightweight components with higher surface finishes, barrel tools are leveraged by machine shops to improve productivity and surface finish of machined parts.

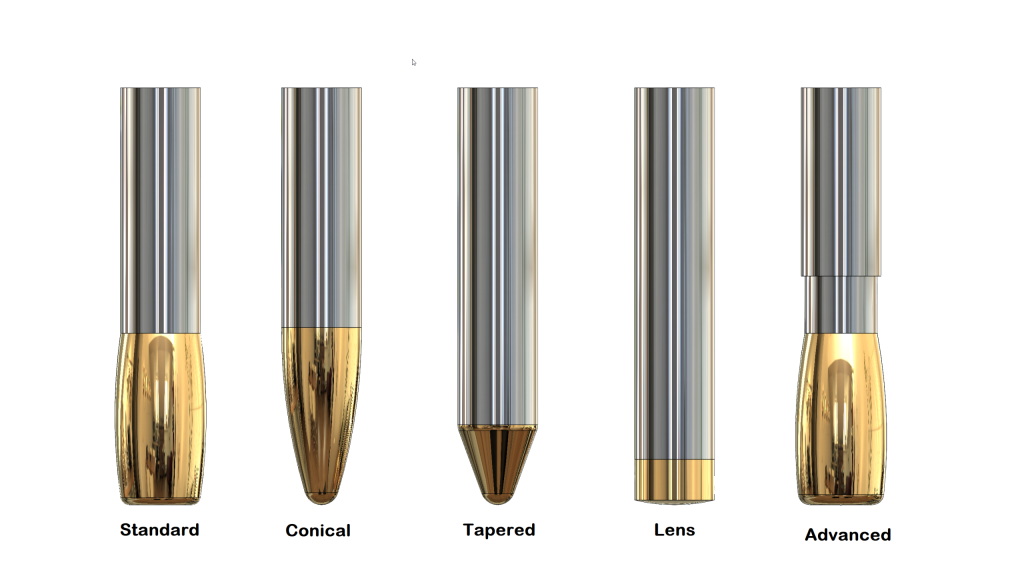

HCL Technologies (HCL), a leading global technology company, announces the addition of barrel tool support in HCL CAMWorks Version 2022. CAMWorks now supports standard, conical tangent, tapered, lens and advanced user-defined barrel tools utilized in Computer Numerical Control (CNC) milling machining operations.

Barrel tool support was added in direct response to CAMWorks customer feedback and is beneficial for mold makers and manufacturers of complex parts in industries such as automotive and aerospace. As demand increases for lightweight components with higher surface finishes, barrel tools are leveraged by machine shops to improve productivity and surface finish of machined parts. Barrel tools reduce cycle times for finish and semi-finish milling operations with increased stepdown into the material with each pass, and due to their unique tool geometry, also provide improved surface finish with fewer cutting passes.

With the new Barrel Tool interface in HCL CAMWorks Version 2022, users can now view, edit, and save barrel tools in the CAMWorks Technology Database (TechDB). And barrel tools can also be filtered, identified, and added to the user-specific tool cribs in CAMWorks. Options for maximum diameter and corner radius of the barrel tools are also included in this new HCL CAMWorks Version 2022. CAMWorks will notify the user if the tool geometry falls outside the defined parameters.

Support for barrel tools in HCL CAMWorks expands the technologies available within integrated CAD/CAM to accelerate production and streamline machining.