Bodor Laser’s all-in-one profile cutting solution for structural steel fabrication

Bodor Laser’s all-in-one profile cutting solution for structural steel fabrication

Federal infrastructure outlays and private-sector capital spending are fueling a new growth cycle in North American structural steel. Bodor's one-stop profile-processing solution — the U3000 and the Hicut Fiber Laser Cutter—is powering profile fabrication in North America's structural steel industry with efficiency and precision.

Federal infrastructure outlays and private-sector capital spending are fueling a new growth cycle in North American structural steel.

Bodor's one-stop profile-processing solution — the U3000 and the Hicut Fiber Laser Cutter—is powering profile fabrication in North America's structural steel industry with efficiency and precision.

Conventional I- and H-beam workflows are complex and prone to positioning errors—especially when complex patterns and cut-outs are involved. Bodor's profile solution covers five steps: hole-making, beveling, notching, marking and cutting, and supports cyclic processing of cutting, loading and unloading. With Tekla integration and the built-in Intelligent Deviation-correction Positioning function, the solution reproduces every detail as designed in profile, ensuring smooth on-site assembly.

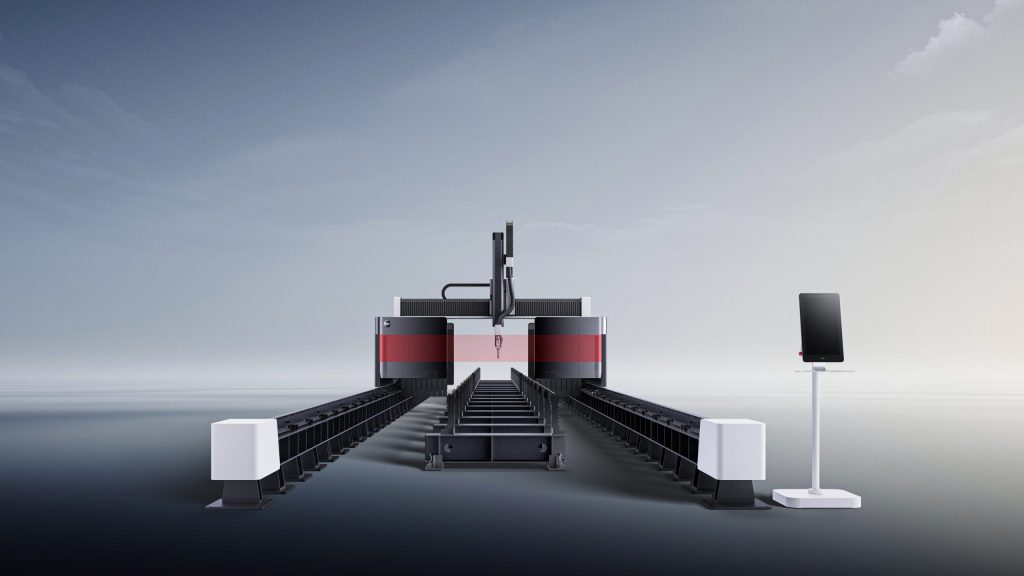

U3000 Professional Multi-task Fiber Laser Cutting Machine

The Bodor U3000 handles profiles, sheets, and tubes within a single machine. With a maximum processing length of up to 110.24 inches, multiple worktables can be configured to enable continuous cycles of loading, cutting, and unloading across different materials.

Key functions:

- Profile Cutting: Processes standard and irregular structural steel for hole-making, bevel cutting, notching, marking, and cutting.

- Sheet Cutting: Enables hole-making, straight cutting, and bevel cutting of sheet materials.

- Tube Cutting: Handles hole-making, beveling, intersection cuts, and through-cuts for square and round tubes.

- Flexible Installation: An optional steel base makes installation easier

Hicut Professional Profile Fiber Laser Cutting Machine

The Bodor Hicut is engineered for fully automatic processing of I-beams and H-beams, integrating loading, hole-making, notching, beveling, cutting, and unloading into one streamlined workflow without manual intervention.

Highlights include:

- Rapid Loading, Intelligent Zoning: Loading takes less than 20 seconds; unloading automatically groups workpieces by length.

- One-pass Lock Notching: The laser head maintain optimal standoff, completing lock notching in a single step — no secondary grinding required.

- Five-axis Linkage: A laser head with 180° reciprocating movement, combined with A/C/X/Y/Z axis linkage, enables full-angle, high-precision processing of H-beams

Both models are deployed by structural-steel manufacturers across North America, supporting applications in infrastructure, machinery and shipbuilding. The performance and responsive service have earned strong customers recognition.

As of 2024, Bodor reports six consecutive years at the top of fiber laser sales. The company backs its core components—Bodor Laser (laser source), Bodor Thinker (control system), and Bodor Genius (cutting head)—with a five-year warranty.

In North America, Bodor is expanding its service team and strengthening local spare-parts inventory. According to a Bodor representative, the company will continue to innovate and further reinforce its service network to better support local manufacturers.