Acme Threading Inserts

Acme Threading Inserts

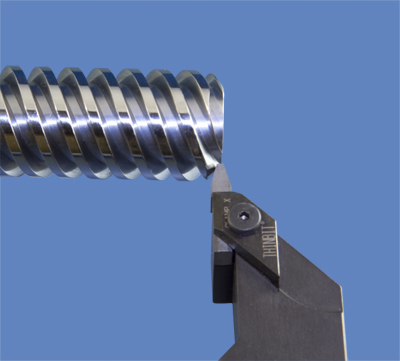

THINBIT, manufactured byKaiser Tool Co., announced the expansion of its GROOVE 'N TURN line with ACME THREADING inserts.

THINBIT, manufactured by Kaiser Tool Co., announced the expansion of its GROOVE 'N TURN line with ACME THREADING inserts.

The inserts are designed to cut thread sizes 4, 5, 6, 8, 10, 12, 14 and 16 threads per inch. Tools have geometry to cut standard 29° acme thread profiles. Inserts can be used to cut centralizing or stub profiles by overcutting. The inserts can be used for internal acme threads on parts with bore diameters of 1.250" and larger.

Available in submicron-grain carbide grades for ferrous and nonferrous materials either uncoated or with TiN, TiCN, TiAIN or diamond film coatings. The inserts can be used on conventional, Swiss-type and CNC machines.

Toolholders are available in square shank size 5/16" through 1-¼" and round shank sizes ½" through 1" with straight and 90-degree presentations. GROOVE 'N TURN ACME THREADING inserts fit existing "L" series THINBIT toolholders.