8.5 version of CAMIO CMM Software

8.5 version of CAMIO CMM Software

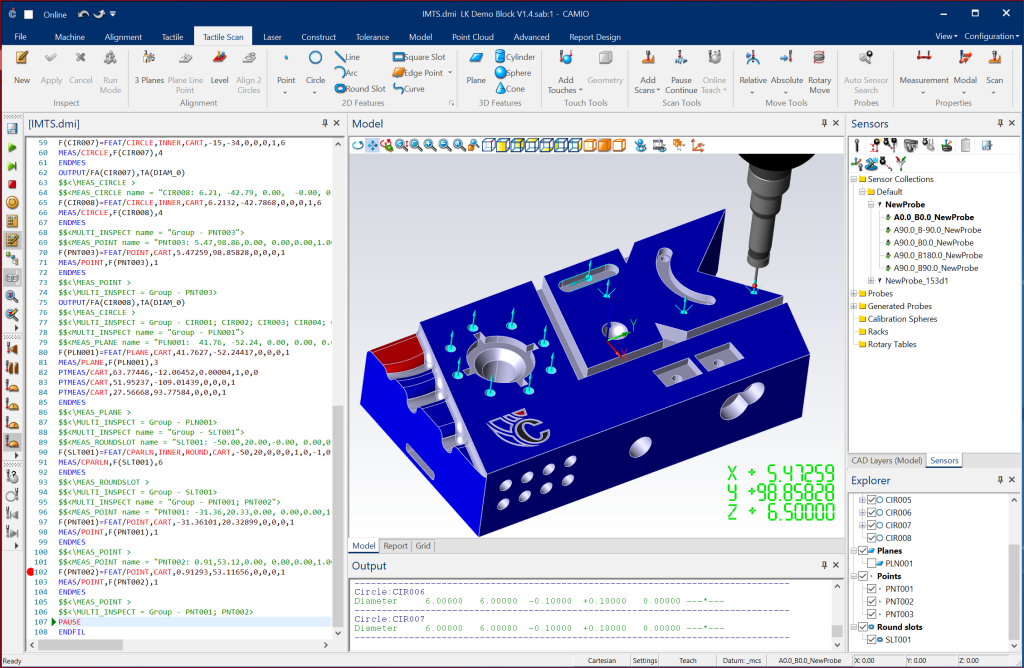

Metrology software has challenges in most application environments, and LK Metrology's new 8.5 version of its CAMIO coordinate measuring machine software has a range of new features to help meet those challenges.

Metrology software has challenges in most application environments, and LK Metrology's new 8.5 version of its CAMIO coordinate measuring machine software has a range of new features to help meet those challenges.

The CAMIO software has become the "software of choice" for many of the world's largest manufacturers because it allows the user to focus on accelerating lead times and improving product quality. Regardless of whether inspecting stamped, molded or machined parts, CAMIO drives accurate and efficient inspection programs for geometric features along with full surface analysis with part-to-CAD comparisons. CAMIO's interoperability across CMM platforms, sensor technology and manufacturing sites becomes its unique advantage.

The new CAMIO 8.5 software includes the following features/enhancements:

1. Programming Updates

- Reorganizing of RPS Alignments

- Improvements in angle between tolerances to toggle between acute, obtuse supplementary angles easily

- More precise and pronounced warning messages for users when setting machine/program parameters outside of min/max limits

- The GOTO command now allows the user to specify the number of axes for move

- Updated ACIS CAD engine and support third-party CAD format

2. CAMIO User Interface Improvements

- Window docking was significantly improved

- CAD layers are now displayed in a separate window which provides easier access

- CAD orientation buttons now allow user to keep current zoom level

- Mouse/pointer coordinates now shown in the status bar allows for quick estimation of dimensions

3. Laser and Point Cloud Improvements

- New detection offset parameter for point detection

- Export of point clouds in Geomagic GDP format

4. Ease of Use

- Improvements in the setup of the Machine Launch Utility for offline programming

- Additional options for opening and/or printing CAMIO reports

- Ability to relocate a single stall of rack instead of all the stalls

5. Probe Head Support

- The Renishaw PHS1 servo head and autochange rack are now supported

- The Renishaw SP80 head and autochange rack are now supported

Dennis Freimark, LK Metrology's North American chief software applications engineer explains, "Common practice is to provide a couple of new releases of metrology software like CAMIO every year, but in 2018 LK Metrology acquired the Nikon CAMIO CMM software business and needed to rebrand it, refresh the interface and implement a new licensing mechanism. While the re-branding took a significant amount of work and delayed the possibility for a second major CAMIO release in 2018, we were still able to add many new features and enhancements for out customers, some of which are listed above."

Several of the significant additions were: 1) The new ability to interface with Geomagic's 3D-data processing software that is used in 3D scanning solutions to create accurate models from scanner data, or for quality control and measurement applications; 2) Support for the Renishaw PHS1 head system along with the ACR2 autochange rack. ACR2 is a modular extension arm change system for the PHS1 servo positioning head that allows any number of racks to be positioned on a pillar anywhere within the machine volume; 3) Support for the Renishaw SP80 head; and 4) Changes to the docking behavior of the windows to allow users to more easily customize the interface for a specific task or application.

Freimark adds, "The shift from Nikon CAMIO to Lk Metrology CAMIO has been a smooth transition for our customers, and the new 8.5 version incorporates many of the needed enhancements that provides CMM users with greater measurement flexibility for better product conformance."