END USER: Lowercase, (212) 510-7621, www.lowercasenyc.com

SOLUTION PROVIDERS: Axis Inc., (908) 429-0090, www.axisnewjersey.com; Robotiq, (888) 762-6847, www.robotiq.com; Universal Robots USA Inc., (844) 462-6268, www.universal-robots.com

CHALLENGE: Cost-effectively integrate automation into the production of eyewear frames.

SOLUTION: A collaborative robot tooled with an easy-to-use, flexible gripper.

Since the 1980s, foreign interests have bought U.S. eyewear manufacturers that produce high volumes of acetate frames, temporarily halting domestic production in the process. Two years ago Brian Vallario, an architect, and Gerard Masci, a finance worker, decided to help bring back U.S.-made acetate frames. They launched Lowercase in New York and began production in January.

From the beginning, the two founders understood that automation offered an avenue to lower production costs without sacrificing quality. They researched a variety of different robots, including some highly industrialized offerings. However, they quickly realized that purchasing a robot and integrating it into production carried two different price tags.

“The cost to automate was extremely high, but we were always able to get our heads around that because of the value that the robot would add to the process,” Masci said. “The main problem was that the integration cost of most robotic solutions was three to four times the cost of the solution itself.”

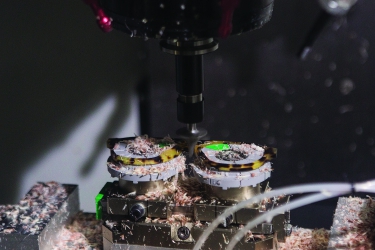

Lowercase machines an acetate eyewear frame. Image courtesy of Lowercase.

Integrating an industrial robot can cost hundreds of thousands of dollars, according to Vallario. “That wasn’t really possible for us.”

The high-cost scenario changed with the assistance of Axis Inc., a Somerville, N.J., distributor of industrial automation equipment. “When Lowercase came to us with their design concept, our automation engineers put together a cost-effective solution that was flexible enough to be redeployed as their business grew,” said Cynthia Kradjel, account manager for Axis.

She said Axis recommended a UR5 collaborative robot from Universal Robots USA Inc., Ann Arbor, Mich., because it is easy to program and change how the robot is deployed. For the end-of-arm tooling, Axis chose a two-finger gripper from Robotiq, Lévis, Quebec. “We felt that it can accomplish the types of movements in a very repeatable and practical way,” Kradjel said.

Lowercase ordered custom fingers and added rubber padding at the contact points to more effectively hold the acetate parts. The relatively soft plastic doesn’t require a lot of TLC, Vallario noted. “You can be pretty rough with it until it goes through the finishing process.”

Flexibility and ease of use were the gripper’s two primary attractions, Vallario said. Programming the gripper is done on the same touch pad with graphic interface that is used for programming the robot. “The gripper is priced great, but being able to make adjustments on the fly and make changes to its fingers are big benefits. It integrates right in with the robot.”

Axis also introduced Lowercase to automation integrator Jeff Richlin, president of Richlin Manufacturing Inc., Farmingdale, N.Y. He designed a platform where the robot stands and a solenoid-based solution so the robot can communicate with the CNC machine, placing parts in the machine and removing them as needed. In addition, Richlin set up the wiring and pneumatic controls.

The integration took a week and cost about 25 percent of what Lowercase paid for the automation equipment, Vallario said, who programmed the robot’s movements. “I don’t come from an engineering or robotics background, yet, within a couple days, we had it up and running. It’s quite simple.”

To machine the frames, Lowercase mounted two custom vises onto a rotary indexer in the machine. The robot picks up the raw material and loads it into the vise that clamps along the part’s outside edges so the machine can cut the shapes of the lenses and their grooves, closes the door and presses the “go” button. It then removes the part, the indexer flips over, the robot places the part in the second vise, which has two lens-shaped discs that expand to hold the part from inside the frame, and the machine cuts the exterior profile. The robot then removes the finished part and places it in a bucket.

Each production batch in the CNC machine averages 500 units, with around 30 to 40 units of each frame style.

Next, the eyewear goes through numerous finishing steps before it is packaged and shipped, Vallario said. This includes four different barrel-tumbling processes, with each tumbling consuming 22 hours, and a manual buffing operation.

Even though part volume is under the capacity of the three-person shop, Vallario said automating work is important.

“Eyewear production is a very labor-intensive process, and we are such a small team that any improvement we can make on our efficiency is huge,” he said. “Having a product that allows me to sit at the computer and work on design or go work on the more labor-intensive stuff that can’t be done by machines is a big plus for us.”

Related Glossary Terms

- arbor

arbor

Shaft used for rotary support in machining applications. In grinding, the spindle for mounting the wheel; in milling and other cutting operations, the shaft for mounting the cutter.

- buffing

buffing

Use of rapidly spinning wires or fibers to effectively and economically remove burrs, scratches and similar mechanical imperfections from precision and highly stressed components. The greatest application is in the manufacture of gears and bearing races where the removal of sharp edges and stress risers by power methods has increased the speed of the operation.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- industrial robot

industrial robot

Robot designed for industrial use. Primarily used as a material-handling device but also used for changing tools, assembling parts, and manipulating special tools and measuring devices. Depending on design, an industrial robot can be programmed to perform a task by means of a controller, or it can be “walked” through the required movements by utilizing a digitizing system that translates movements into commands that the robot can be “taught.” See robot; teaching pendant.

- robotics

robotics

Discipline involving self-actuating and self-operating devices. Robots frequently imitate human capabilities, including the ability to manipulate physical objects while evaluating and reacting appropriately to various stimuli. See industrial robot; robot.

END USER: Lowercase, (212) 510-7621, www.lowercasenyc.com

SOLUTION PROVIDERS: Axis Inc., (908) 429-0090, www.axisnewjersey.com; Robotiq, (888) 762-6847, www.robotiq.com; Universal Robots USA Inc., (844) 462-6268, www.universal-robots.com

CHALLENGE: Cost-effectively integrate automation into the production of eyewear frames.

SOLUTION: A collaborative robot tooled with an easy-to-use, flexible gripper.

ARTICLES

ARTICLES