Finish boring tools that ‘just work’

Finish boring tools that ‘just work’

Reduce scrap and tackle challenging jobs. Adjustable finish boring heads.

END USER: Southland CNC Inc., (706) 778-0369, www.southlandcnc.com.

CHALLENGE: Reduce scrap and tackle challenging jobs.

SOLUTION: Adjustable finish boring heads.

SOLUTION PROVIDER: BIG Kaiser Precision Tooling Inc., (888) 866-5776, www.bigkaiser.com.

Each time Steve Jobs took the stage at an Apple product release event, attendees could rely on him summarizing the performance of the company's newest gadget with one confident phrase: "It just works."

Just because the phrase holds water for a tech company whose products evolve each year, there's no reason it can't also apply to a boring head designed to perform consistently after years of use.

At Southland CNC Inc., a Cornelia, Ga.-based job shop, two lines of boring heads have not only ensured parts are machined to tight tolerances, but have generated new business. The Kaiser 112 and 310 series of finish boring heads from BIG Kaiser Precision Tooling Inc., Hoffman Estates, Ill., have reduced scrap rates, exceeded the performance of customer-supplied tooling and earned the loyalty of operators, according to Darren Parks, Southland CNC's process manager and CNC programmer.

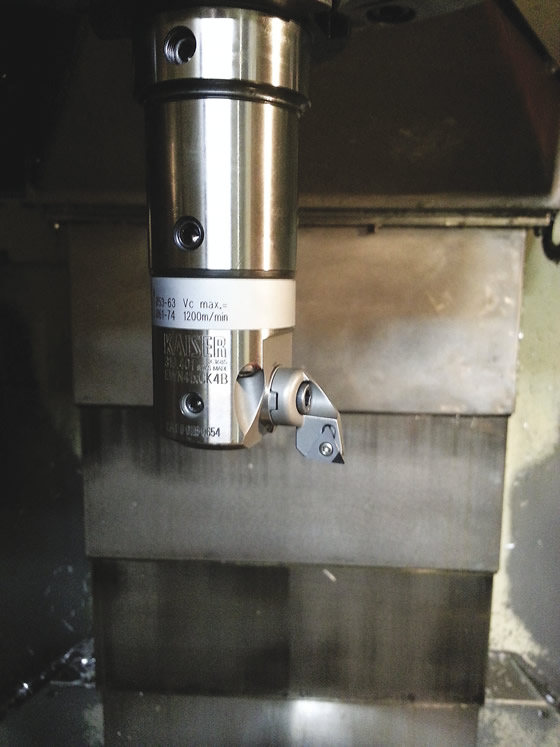

The Kaiser 310 finish boring head is easily adjustable with an Allen wrench and holds true while changing and tightening the tool's diameter path.

Most of the parts the shop bores with the heads are for the aerospace industry, and are produced on vertical machining centers.

Much of the material Southland CNC machines is aviation-grade die cast aluminum. The shop also manufactures some sand cast parts. Depending on the workload, the 40-employee company runs two or three shifts at its 15,000-sq.-ft. facility, located about 75 miles northeast of Atlanta.

Parks explained that when he receives a blueprint and quotes a job, the hole diameter doesn't influence the cost because he knows the boring heads work. "We look at other factors to see what could cause us problems, scrap or downtime."

One challenging job involves machining aluminum that has layers of steel laminated into it for aircraft engine magneto ignition systems. Because the steel helps generate the power for the spark plug, a boring head cuts both steel and aluminum. Interrupted cutting a hole 2" to 3" (50.8mm to 76.2mm) deep only adds to the challenge.

A coil inside the housing and a magneto shaft, which has steel laminations and is magnetized, also assist in generating power, Parks added. As the magneto shaft passes in front of the steel in the magneto housing, the coil is charged and the spark plug ignites.

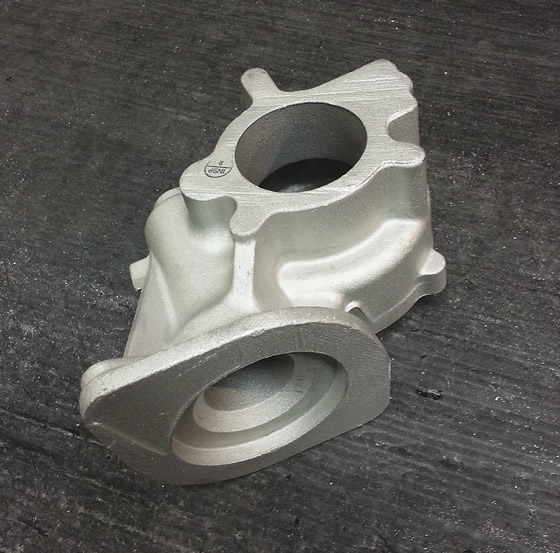

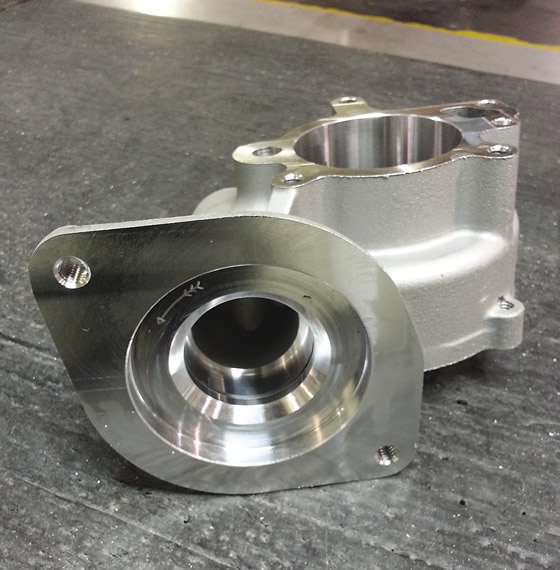

Before (above) and after (below) photos of a starter housing component that Southland CNC accepted after seven other machine shops refused the job. This job requires applying seven boring heads, ranging from 0.314" to 4.287" (7.98mm to 108.89mm) in diameter.

Issues with supplied boring heads entailed frequent readjustments, a task too time-consuming for a single operator to perform.

Once Southland CNC started applying the Kaiser heads, Parks knew he could trust the adjustment dial. If Southland CNC receives customer-supplied tooling that's not up to par, it replaces them with its BIG Kaiser tools. "If you have a 15- or 20-minute cycle time and you throw every third part away because the diameter of the bores is incorrect, you've gained nothing at the end of the day," Parks said.

Southland CNC has 30 Kaiser boring heads: 20 in production and 10 on standby. Some have been in use for 18 years with only the insert, normally PCD-tipped, requiring replacement.

Southland CNC keeps detailed data on its machining operations, which illustrate how well the boring heads works. "There are several times where the Kaiser boring heads have increased our output at least 25 to 40 percent," Parks said.

And because the boring heads and carbide bars are adjustable, Parks can train unskilled operators to use them instead of relying on a machinist being paid $30 to $40 per hour.

The 112 series heads bore holes 0.016" to 2.126" (0.4mm to 54mm) in diameter, while the 310 hits holes 0.590" to 8.000" (15mm to 203.2mm). Both accommodate through-spindle coolant. Southland CNC bores cavities from 0.236 " (6mm), with a tolerance of 0.0002" (6µm), to 4.287" (108.89mm), with a tolerance of 0.001" (0.0254mm).

Richard Bevers, industrial sales representative at BIG Kaiser, is confident that when a customer adjusts a head only, say, 0.0005" (0.0127mm), he will know that's what the bore will change. "When they lock the lock screw, it won't affect the adjustment."

Perhaps the most telling anecdote Parks recalled about BIG Kaiser tooling is when a new customer came to Southland CNC with an extraordinarily difficult part to machine. The customer had previously visited seven other machine shops and none of them felt they could process the starter housing component. "They told us if we couldn't do it to print, they were going to scrap the project," Parks said.

After setting up the tooling fixtures with seven boring heads, Southland CNC was able to finish the part better than the blueprint's specifications, Parks said. "We did it right out of the gate without a second try." Southland CNC still produces the part, and can make about 40 of them per day.

When the BIG Kaiser boring heads are part of a properly designed setup, Parks knows he won't need to scrap a part on the first run. "Once the part is positioned and the dial adjusted, the second, third and rest of the parts will hold true, and we just keep rolling," he said. In other words, it just works.