Deburring: an essential but often overlooked process

Deburring: an essential but often overlooked process

With so much attention given to improving machining processes, machinists, programmers and engineers at times forget about simple, but necessary, processes like deburring.

Lots of attention is given to improving machining processes. New productivity-boosting developments for drills, mills, boring tools and turning tools abound. Advanced milling and turning techniques are always under development, and software companies regularly announce new features that promise to slash cycle times. Machine tool builders and CNC manufacturers are creating ever-faster machines and controls capable of keeping pace with advanced machining techniques.

It is easy for machinists, programmers and engineers to get lost in the possibilities and forget about simple, but necessary, processes like deburring. Very few parts, if any, don't need to be deburred. Nearly every machining process leaves some sort of burr that must be removed.

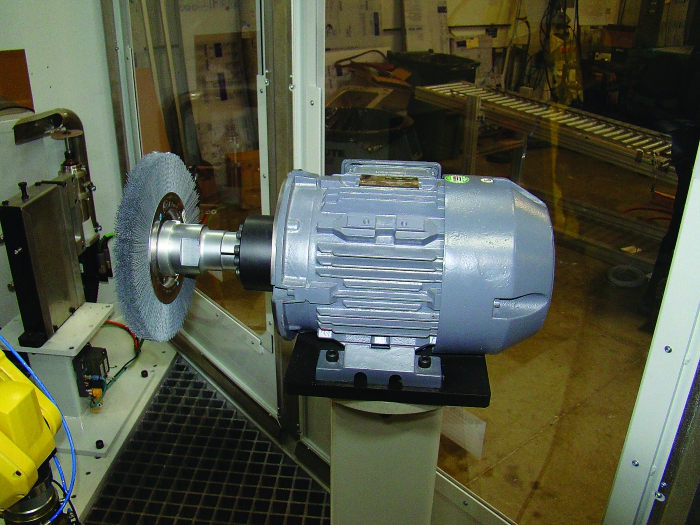

A host of methods exist for deburring parts, such as this motorized brush from the Deburring Applications Laboratory at Matrix Design LLC. Image courtesy of Alan Richter.

In the not-so-distant past, young tool and die apprentices were trained to deburr parts for journeyman tool and die makers. It was a practical activity that taught patience and hand skills.

Deburring small, intricate parts is almost an art form, requiring fine motor skills, an understanding of critical part features and attention to detail. In some industries, like aerospace, deburring has been considered a trade and there have been people who have spent their entire careers at the burr bench.

Deburring is an important skill; it should be given attention because removal of burrs is critical to safety and quality.

The Problem With Burrs

Burrs can cause issues in downstream machining processes by preventing proper location of the part in a fixture or result in erroneous measurements when a burr interferes with a metrology device.

Depending on the lay, a burr may not be detectable visually or by feel, making it easy to overlook. This is often the case with close-tolerance holes. When a burr is left on the edge of a hole, plugs and thread gages may not fit properly, resulting in rejected parts.

Having burrs on parts can also interfere with other measurements.

When I worked for a manufacturer of power steering gears, an automated assembly machine was a continual source of part failures. The machine screwed ball joints into the steering unit and then verified that the parts had been assembled correctly. If a part went in farther than expected, the machine alerted us about a bad part.

After many rejections and many dollars spent investigating, we found that burrs left from machining were getting trapped between the parts, causing erroneous measurements. We eliminated the burrs, and the problem went away.

Burrs left on parts can also injure workers. Most of the recordable injuries at our shop are lacerations to hands. Many of these injuries come from parts that were not properly deburred. Therefore, removing burrs before moving parts to the next operation is critical to maintaining a safe working environment. It is given considerable attention at our shop.

Significant problems can also arise if a shop ships an improperly deburred part.

I worked in an aerospace shop that made hydraulic components. The components had small orifices that could easily become blocked by burrs if they were to break free. Blockage of the orifices could result in a failure of an aircraft's hydraulic systems—a potentially life-threatening event.

Valuing Deburring Skills

Deburring is often performed by hand with simple tools, giving some the impression that it is a task that does not add value. This attitude and the desire to cut costs have created an environment that minimizes the importance of developing and cultivating effective deburring processes, as well as training on the proper techniques.

It seems that many engineers, operations leaders and machinists no longer value the skills needed to properly remove burrs. Only after a part fails do they begin to emphasize deburring.

I experienced a situation with one of my employers where a newly hired employee was assigned to deburr an extremely expensive part. The "new guy" was not a machinist and had little experience around machine tools or machining. It was decided he should deburr until he completed his training as a machine operator.

He was given a die grinder, a box full of burr bits and 5 minutes of instruction and then was set free to remove burrs from a $250,000 component. In his zeal to do an excellent job, he removed far more material than was required and altered the geometry of the part. We were able to salvage the part, but it severely interrupted the schedule, almost delaying shipment to the customer.

Deburring is almost always considered a secondary operation performed after machining, by hand and off the machine. A better option is to develop machining processes that eliminate the need to deburr off the machine.

Sometimes, burrs can be eliminated by programming a machine's CNC to add a deburring operation while the part is on the machine. Examples include programming a chamfering-tool/" data-glossary-id="142011" data-glossary-teaser="Cutter or wheel that creates a beveled edge on a tool or workpiece." title="Cutter or wheel that creates a beveled edge on a tool or workpiece." aria-label="Glossary: chamfering tool">chamfering tool to take a pass along the edge of a hole, milling a chamfer on a sharp edge and programming a radius on the edge of a part.

In other situations, special-purpose deburring tools can be purchased. These tools are made with retractable blades that deburr both sides of a through-hole. Many machine solutions exist to support deburring in the machine tool.

Deburring is an option that is critical to quality. When its importance is minimized, serious quality and safety issues case arise. Removal of burrs should be considered during process design and should also be part of an organization's training regimen. Learning to properly remove burrs should be considered as important as learning to use micrometers and calipers.