Be cautious when changing coolant

Be cautious when changing coolant

A company running a centralized coolant system with neat oil seeks help from the Grinding Doc. The shop's oil supplier is promising great things if the shop switches to a newer oil product. But it seems like such a grand undertaking.

Dear Doc: Our company runs a centralized coolant system with neat oil. The oil is old, and our oil supplier is promising great things we if switch to a newer product. But it seems like such a grand undertaking. What's your take?

The Doc Replies: If you're running a central system with thousands of gallons of coolant, doing a wholesale coolant change is a risky venture. Two companies have told me they changed their coolant over a weekend, ran the new coolant for 2 weeks, experienced terrible burn problems and switched back to the old coolant. The hundreds of thousands of dollars in coolant costs wasn't the killer; it was the 2 weeks of lost production.

Curiously, they didn't even test the new coolant before switching, simply taking a leap of faith and trusting the coolant companies.

When one of my customers says he's thinking of trying a new coolant, I set up an evaluation program. This involves isolating one grinder with a separate coolant tank and running three batches of different parts under standard production conditions with a standard coolant. Then, we put in the new coolant and run the exact same batches of parts under the exact same conditions. When doing this, we don't just inspect the parts for visual burn, because that wouldn't tell us much. We measure form loss. In addition, we use my Grindometer device to measure grinding power.

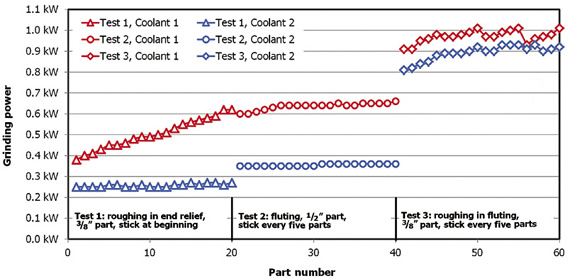

The figure shows results from a customer who grinds tungsten-carbide endmills. The company tested two coolants while grinding three types of parts. The results show the power was consistently lower when using coolant No. 2 than coolant No. 1.

Grinding power is shown for two coolants. For a given set of parameters, lower power means lower workpiece temperatures.

But that's not good enough. In addition, we also measure wheel wear by grinding 100 or more parts and then measuring core breakdown. This generates hard data based on real science. What's more, we can tweak the new coolant over several weeks, putting in different additives to detect any changes. We can also keep an eye on bacterial growth, foaming and other pesky coolant issues.

Once a parts manufacturer is comfortable with a new coolant, the fluid goes into the centralized system. This is far less risky than the let's-see-what-happens approach.

Keep in mind, there still may be issues with the new coolant, even if it's better. Your operators have been tweaking speeds and feeds based on that old coolant for years. The interaction at the wheel/workpiece interface will change with the new coolant, requiring additional tweaking of speeds and feeds, as well as wheel grades. CTE

About the Author: Dr. Jeffrey Badger is an independent grinding consultant. His Web site is www.TheGrindingDoc.com. He'll be giving his High Intensity Grinding Course Nov. 6-8 in Gävle, Sweden, and his Carbide Master-Grinder Clinic Dec. 10-12, hosted by Rollomatic, Mundelein, Ill.