Editors' Blogs

As product miniaturization continues, micromachining continues to make inroads into the manufacturing industry, and CTE will once again provide a special section about micromachining in our May issue. At the other end, I’ve noticed more developments in large-part machining, and, coincidentally, our April issue will include a focus on that topic.

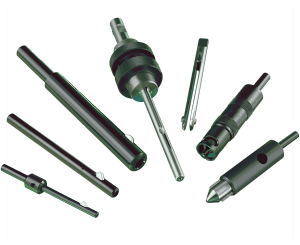

E-Z Burr Tool Co. will continue to operate as an independent entity out of the deburring tool manufacturer’s Livonia, Mich., facility, with little or no change in procedures or processes, reports purchaser Cogsdill Tool Products Inc., Camden, S.C. The sale closed Jan. 3.

Although millions of manufacturing jobs may need to be filled in the years to come as baby boomers continue to retire, many manufacturers already struggle with unfilled positions. One efficient way to combat the problem is by improving company websites, said Claudia Pennington, co-founder and CEO of DIY Marketing, Marietta, Pa.

Every day, it happens. Someone from Houston calls, or maybe San Francisco, peddling precision-machined parts from China. Then there are the emails from people with fake names—like Lily, Annie and Susan—overflowing my inbox with offers of low part costs and excellent service. Please, China, I don’t want to buy machined parts from you. No metal stampings. No plastic injection molds or 3D-printed prototypes. And at the risk of offending those who do, you shouldn’t either.

The week after CemeCon Inc. held a ribbon-cutting Jan. 17 to officially open its new 15,000-sq.-ft. headquarters and CVD diamond coating facility, I spoke with Gary Lake, company president, to discuss the expansion and developments in cutting tool coating technology. The opening marks the fourth expansion of production capabilities since the company, which is a subsidiary of Wuerselen, Germany-based CemeCon AG, was founded in 1998 and the third increase in capacity for the CVD diamond process since 2014.

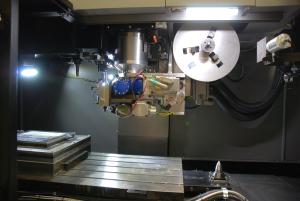

Rollomatic Inc. hosted an open house Nov. 7-9 at its headquarters in Mundelein, Ill. In addition to displaying the latest Rollomatic and Strausak grinding machines, as well as a Platit tool coating machine, the event offered attendees an opportunity see a demonstration of Rollomatic’s software for Industry 4.0.

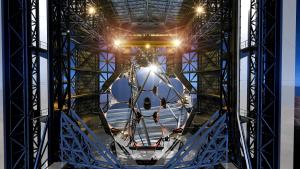

Imagine a beam of light traveling unimpeded for 13.5 billion light years, only to get deflected and distorted just before being captured by a telescope. That is something the builders of the Giant Magellan Telescope are working hard to avoid.

Not every holemaking job requires a high-performance, solid-carbide or PCD-tipped drill with an advanced coating. For many, a HSS jobber drill will suffice.

In connection with the abrasive waterjet machining article scheduled for our March issue, I spoke with Jim Draper, owner of Rocky Mountain Waterjet, Greeley, Colo., who said when a parts manufacturer finds that waterjetting is a suitable process for a part or family of parts, the decision to outsource that work to a waterjet job shop or buy a waterjet machine for in-house production depends on the part quantity.

To reduce training time and improve worker safety in the high-risk environment of industrial manufacturing, Tobii Pro Insight conducts eye-tracking studies. For example, the Stockholm, Sweden-headquartered company reported that its research consultants conducted an eye-tracking study at the metal foundry of H&H Castings Inc., York, Pa., and the attention-based study revealed unique insights that will contribute to quicker onboarding of new workers, new efficiencies in its operations, new training guidelines and reductions in the risk of accidents.

My October 20 post on adding capabilities to your current CNC brought a response from a reader who who shares a problem. “We have a few Kitamura MyCenter 4XiF VMCs with FANUC 16iMB controls running daily on our shop floor,” he writes, “The control hasn’t given us a single problem since they powered on for the first time. However, we haven’t been able to get the machines onto our network and we have given up trying.”

A recent CNC Cookbook survey included respondent comments about what they found lacking in their current CNC control. They mentioned inadequate work offsets, lack of web monitoring, limited tool data management and other shortcomings. FANUC Corp.'s Paul Webster explains why for some users, it may not be too late to easily add the capabilities they need.

Good news about the manufacturing economy was shared with members of the United States Cutting Tool Institute who attended the trade association’s fall meeting, held Oct. 7-9 in Coeur d’Alene, Idaho.

Last week's blog post on the successors of Rosie the Riveter inspired a reader to share her own experience as an early woman in manufacturing. Lois Anderson was tasked with walking into plants in Southwestern Michigan to convince dubious managers and workers to use new methods to improve their production quality and efficiency. In the end, she helped them excel.

As part of the newly created 3D/Additive Manufacturing Pavilion at the FABTECH 2017 trade show held Nov. 6-9 at Chicago’s McCormick Place, Fabrisonic LLC’s exhibit showcased the company’s hybrid ultrasonic additive manufacturing (UAM) and subtractive machining capabilities.

The job training programs at Hononegah Community High School and Beloit Memorial High School include job shadowing, mentoring, summer apprenticeships and training workshops at cutting tool manufacturer Regal Cutting Tools, Roscoe, Ill.—but no internships. Working at Regal Cutting Tools means being considered a normal employee, not an intern, even if the worker is there part time and spending his or her days as a high school junior or senior. Although students are allowed time off for academic-related reasons, such as preparing for college admission tests, there are no exceptions for extracurricular activities, such as sports or clubs. “They need to make a decision whether they want to be part of that,” said Plant Manager Dennis Weiland.

A former NFL linebacker, Pete Shufelt credits his post-football career as the owner of Backerworks Manufacturing LLC to the day he asked his high school counselor/football coach about what elective classes to take.

A recent survey has 80 percent of manufacturers and energy companies implementing or developing a digital workplace transformation plan. Only 18 percent are allocating at least a quarter of their budget toward these efforts over the next 12 months, however—and that’s the minimum percentage needed to get started, according to Dan Chalk, director of solution engineering for NTT Data Services, Plano, Texas.

There were a lot of deep discussions about holemaking at UNISIG’s recent open house and seminar series for magazine editors. UNISIG engineers explained different methods of deep-hole drilling, including gundrilling and BTA drilling, and provided an overview of the machines and related systems the company builds to perform these operations. Hands-on demonstrations in UNISIG’s 62,000-sq.-ft. plant augmented the classroom discussions.

In manufacturing, the nature of the work as well as the nature of the workers are changing: What’s a prospective employer to do? Some pre-Manufacturing Day discussion.