Material-specific taps continue to evolve

Material-specific taps continue to evolve

A look back at the use and evolution of sintered powder metal and the PM process that results in a tool substrate that consists of finer, more consistent particles, and yields a stronger, longer-lasting cutting edge.

When Joe Mazzenga got his start in the cutting tool business in 1975, his employer only made taps from poured HSS tool blanks. The company did, however, experiment with sintered powder metal.

PM "was just coming out at that time, but it was not used anywhere near the extent that it is today because of the technological limitations of the time," said Mazzenga, who is now the president of J.M. Sales-USA, Troy, Mich.

The PM process results in a tool substrate that consists of finer, more consistent particles. This yields a stronger, longer-lasting cutting edge. It also lets tool manufacturers specify an alloy content tailored for a specific workpiece material.

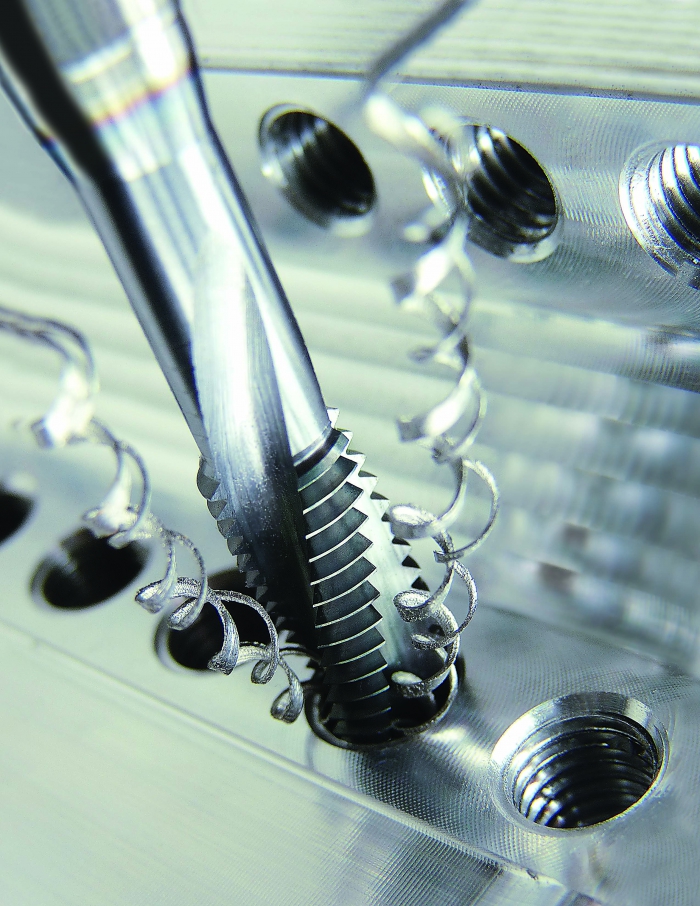

Image courtesy of Wilhelm Becker GmbH & Co. KG.

Like Mazzenga, Raymond E. Moring also has witnessed an evolution in taps since entering the cutting tool industry in 1973. A technical sales marketing specialist at Greenfield Industries Inc., Seneca, S.C., Moring thinks taps, to some degree, always have been designed for specific applications. He added that the practice has become more prominent as more specialized workpiece materials, including exotics and superalloys, have been developed that require threading.

"You had to change some characteristics of the tool," Moring said.

He cited the aerospace industry as the main driver of change from the '70s to today.

"The materials were made tougher, more heat-resistant and to last longer," he said. "You had to machine them differently."

Moring pointed out that the medical industry has not been far behind aerospace in its influence.

"Twenty or 30 years ago, you didn't have the proliferation of materials that could be put into the body for medical implants, like titanium or some kind of chromium-cobalt material," he said. "You have to change the chemistry of the metal so it can stay in the body and last a long time, and that doesn't always help machining characteristics."

When Emuge Corp., West Boylston, Mass., entered the North American market in the 1980s, the aerospace industry was, and remains, a strong manufacturing sector in New England.

"Aerospace manufacturers were starting to use Inconels and titanium in their parts," said Emuge Product Director Mark Hatch. "Those materials were newer generation at the time, resulting in significant learning curves" for tool users and manufacturers.

Emuge offers the Rekord D-TI tap, a blind-hole tap for threading titanium alloys. Image courtesy of Emuge.

He said tap breakage is of high concern for all industries and certainly for aerospace.

"They're making high-cost, safety-critical components," Hatch said. "By the time they get to the tapping operation, which is one of the last processes for some of these parts, tens of thousands of dollars could be at risk from a broken thread. A broken tap, a nonconforming thread that's not gaging correctly or rough, torn threads are some of the problems you can encounter."

More Materials, More Taps

J.M. Sales-USA has sold Hahnreiter taps from Germany in the U.S. and Canada for the past 8 years, and the tap maker frequently tweaks its product line for specific applications.

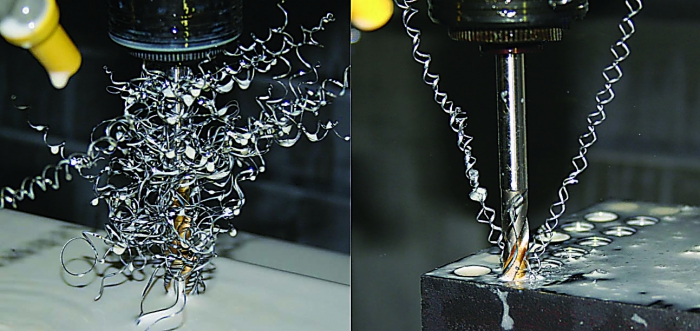

For instance, it recently released the Spiralo 48 TS TiN tap, which is designed to promote chip evacuation when tapping deep, blind holes in long-chipping materials. According to Hahnreiter, the flute geometry prevents the formation of "bird nests"—the stringy chips that wrap around the tool shank and must be manually removed.

Materials are increasingly diversifying, and suppliers of taps are following suit, Mazzenga said.

"I see more and more of what I never had to deal with long ago: the tougher stainless steels, such as austenitic stainless, and the high-temperature alloys, such as the Inconels and Hastelloys, and titanium," he said. "Austenitic, for example, is tough to machine yet stringy at the same time. Hahnreiter developed the Nirofix 48 STY/WC tap just for that in blind holes."

Hahnreiter provides the Spiralo 48 TS TiN tap, which is designed to allow proper chip evacuation for deep, blind holes in long-chipping material. According to the company, the flute geometry avoids the buildup of "bird nests." Image courtesy of Wilhelm Becker GmbH & Co. KG.

Mazzenga said the tap has a special multilayer coating to help resist heat and wear and that the addition of tungsten carbide to the surface provides excellent gliding performance so that hot chips do not stick to the tool.

Nachi America Inc., Greenwood, Ind., has introduced several material-specific taps in the past year, including the Hyper Z SUS tap for threading stainless steel. The tap goes through a hardening process that strengthens the surface to extend its life, according to the company.

"Competitors' taps for stainless steel may be able to run faster," said Nick Lieffers, a cutting tool engineer at Nachi, "but we can give customers longer tool life for a cheaper cost while having high-quality results."

Despite the increase in specialization, the top-selling tap at OSG USA Inc., Irving, Texas, remains its "Do It All" Hy-Pro tap. Although the company sells taps that are much more specialized, as well as a more general-purpose tap not designed for production work, the Hy-Pro tap serves as a bridge between general and specialized.

"It can handle a wide range of stuff," said OSG Applications Engineer Alec Janson, "and that's a good option. We get so much business from that set of taps because people are looking for something that will work on many materials but isn't superhigh-end."

Emuge's MultiTap fills a similar role. Hatch said it's recommended for job shops and manufacturers that thread short and medium runs of parts across a wide spectrum of materials. He said every industry has unique challenges for tapping, such as automotive with its high-volume production and predictable processes.

"Automotive requirements are entirely different from aerospace and the oil industry," Hatch said. "Automotive manufacturers are sweating seconds and need high-speed turnaround and minimal tap breakage. They need to run at warp speed and produce high-quality parts."

Generally Speaking

Mazzenga said although general-purpose taps always will have a market, specialization is how manufacturers make money.

And it's how manufacturers differentiate themselves, he said, adding, "As more and more types of material need to be machined, shops have to be willing to take on the more difficult jobs that they didn't have to do in the past. You don't want to walk away from those jobs if you can help it."

Moring agreed, saying tap life and material machinability are the determining factors.

"If I'm getting by, but then all of a sudden I get a job with an advanced material, then the general-purpose tap won't cut it or won't work correctly," he said.

"A job shop never knows what is coming through the door, from steel to brass to high-temperature alloys," said Lieffers, who nonetheless stressed the value of Nachi America's VTP line of lower-cost, general-purpose taps. "There will always be the cost-conscious customer and someone who just needs a versatile tool, so general-purpose taps will be part of any cutting tools lineup."

Janson said it all comes down to tool life and speed. "Everyone wants to go as quickly as they can and still get the best results possible," he said.

Evolution on Tap

Mazzenga expects continued, incremental improvements to taps to enhance the machinability of certain materials.

"It's not just one area," he said. "It's the materials, geometries, coolant and feed capabilities of the machines."

Hatch concurred and said the bigger technological gains of 15 to 20 years ago have given way to smaller enhancements, with the most notable being coatings.

"Surface treatments are constantly evolving," Moring said. "The coatings people are always developing new recipes that are deposited on the cutting tools. You want coatings that resist abrasion and heat and lower the coefficient of friction, and you keep evolving them."

The recent rise of through-coolant taps will continue as CNC machines improve, Lieffers said. Machine development also may drive more use of carbide taps.

"They're not extremely common because there is so much pressure when tapping," he said. "The carbide is brittle and can break off. But if you have an extremely rigid setup, you can use a carbide tap."

He said, in time, highly rigid machines may become more affordable. "If that happens," Lieffers said, "then you'll have smaller shops that will have higher-quality machines that can handle carbide taps, which will lead to the rise of carbide taps."

If that change occurs, Janson envisions fewer applications for other tap substrate materials, such as HSS, but those materials will never disappear.