Get In The Groove

Get In The Groove

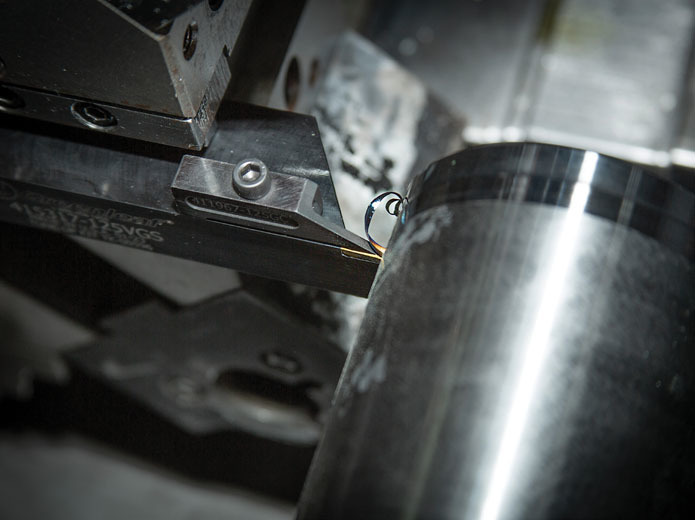

Modern grooving and cut-off systems offer versatile geometries, stronger carbide and ceramic options, smarter cooling and custom tooling for complex parts.

When performing turning operations such as grooving and cutting off, square nose-style inserts are typically used, according to Greg Sage, who is regional product manager of turning – Americas at Kennametal Inc., headquartered in Pittsburgh, Pennsylvania. However, there are limitations with that type of insert. "It doesn't allow you to be as dynamic with it."

A more versatile platform, Sage said, is the toolmaker's Beyond Evolution full radius-style grooving inserts with a greater than 180° cutting edge, which are also able to perform copy turning, profiling, plunging and other operations. "You have the ability to go down, profile back and forth, quickly remove a lot of material and be able to do some fairly complex profiles."

He added that with a full radius insert, an end user is not necessarily going to do a straight plunge. "You do lead-in angles where you start to radius yourself into the cut. Now, you can then go and do your back-and-forth style of passes, where you are creating that groove or profile into the part."

That maneuver works best for large areas, Sage explained, and plunging is best when the width is fairly narrow.

The Beyond Evolution inserts are secured with a single clamping screw, he said, making it easy to swap inserts in the machine. "Or you can have redundant tooling. You can have two toolholders set up, one with a square nose insert and the other with a full radius."

The platform offers multiple different geometries, Sage said, including the company's grooving universal positive and grooving universal negative geometries. The positive one is suitable for straight plunging and grooving applications and has chipbreaker forms even around the side areas to provide effective chip control in all directions, such as when performing side turning. On the other hand, the negative one offers a high degree of edge strength for applications with a low cutting speed and DOC. "It is specifically made to control chips well whether you are plunging or side turning with it."

He added that the positive geometry reduces cutting forces and enhances an insert's shearing capabilities. "The tradeoff is you lose a bit of the edge strength because of the thinner cross sections." Conversely, a negative or more neutral geometry increases edge strength and stability while increasing cutting forces, potentially pushing material more than shearing it. "Nine out of 10 times, trying to reduce cutting forces, especially in grooving applications, is a good thing."

For Beyond Evolution inserts, Kennametal has multiple ways of holding them, including industry standard square shank toolholders and integral boring bars, Sage said. The company also offers modular blades — a blade-style holder that fits the blade into a square shank, round shank or its KM system.

When cutting off and, in particular, grooving, Sage recommends minimizing how much a tool extends out to enhance rigidity and stability, depending on the application. "If you're talking a smaller part where we can go at it with an integral shank that gives rigidity to the whole setup, we're going to go that way."

He noted that the Beyond Evolution inserts have a built-in groove on top to direct coolant to where it's needed as a grooving tool goes deeper into a part. "The coolant works its way down through the finger of the tool and comes out right into that groove on the body of the insert and fans out over the cutting edge."

Carbide and ceramic inserts

Greenleaf Corp. is another toolmaker that offers a comprehensive line of grooving, profiling and cut-off inserts. The Saegertown, Pennsylvania, company reports that its single- ended V-bottom grooving systems enhance the DOC and allow an optimal transfer of cutting forces for carbide and ceramic inserts.

The tool bodies for both types of inserts are the same, said Martin Dillaman, global manager, engineering/ applications project manager for Greenleaf, providing a solid backing as an insert fits into the pocket with the clamping on top.

One significant difference between the carbide and ceramic grades, such as the silicon carbide whisker-reinforced Al2O3 ceramic ones, is that a ceramic insert can be run at a significantly higher cutting speed than a carbide one, with metal removal rates for ceramic up to 10 times higher than carbide, Dillaman explained. The faster speed generates more heat at the tool/ workpiece interface, potentially causing the tool body to fail. To counteract that, he recommends applying high-pressure coolant directly at the cutting zone whenever possible. "It's one of the drawbacks with ceramics."

Another way to counteract heat causing deformation and catastrophic failure of the toolholder is to coat the top of the clamp where chips would strike to gain more clamp life, he added. "Usually, on a special application we would add that coating to the clamp face. We've done some special designs as well where we plumb coolant through the clamp, trying to get coolant closer to the cutting edge to aid in chip removal or control that chip coming off."

Regarding coatings on the inserts themselves, Dillaman estimates that less than 10% of Greenleaf's carbide inserts are sold uncoated while an uncoated ceramic insert is a standard offering. However, the company does offer coated ceramic grades, such as WG-600, which is suitable for grooving hardened steel, heat-resistant superalloys and select stainless steels. "[The coating] adds additional protection onto the insert, which gives you more speed capability on the ceramic side."

To hold the inserts, Greenleaf offers two different styles of tool bodies, he said. One features a milled nest that holds the V form on the bottom of the insert along with a specific shape, such as a round pocket, to accept the geometry of the insert. The replaceable nest design has a small cartridge that fits into a key onto the holder itself to allow a user to replace the nest portion without replacing the entire holder. "You can replace that if it gets damaged. It tends to be the area that sees the most abuse in a lot of operations."

In addition to the nest, if needed, Dillaman noted that Greenleaf supplies tune-up kits for toolholders that provide all the other replacement components, such as clamps and screws, to allow users to return holders to nearly new condition. "It gives you all those components that you are able to install on the toolholder instead of having to order each individual component."

Swiss-style complexity

Because part manufacturers frequently perform internal grooving on Swiss-style machines, Guhring Inc. in Brookfield, Wisconsin, offers its System 104, 106 and 108 stick inserts and holders, said Paul Larson, product manager of drills, thread mills and grooving systems. In addition to internal grooving, the tools are suitable for a variety of operations, including boring, profiling, chamfering, slotting, threading and broaching. "As parts are getting complex, you need complex tooling to handle that."

The System 104, 106 and 108 have 4 mm (0.157"), 6 mm (0.236") and 8 mm (0.315") shanks, respectively, to suit the bore sizes that fit the majority of the applications Guhring is targeting, Larson said. When a "beefier" tool is needed, the toolmaker offers the non-stock standard System 110 with a 10 mm (0.394") shank. "We can rapidly put on the cutting geometries that the customer needs."

For external radial and face grooving, as well as threading and parting off, he noted that Guhring offers System 305 triangle indexable inserts with three cutting edges. "You are not hindered by the diameter of the bore. Your only limitation is the size of the machine."

In addition, Guhring reports that it offers System 222 indexable inserts and holders with and without internal cooling for parting off. The chipbreaker and cutting geometry are pressed to size into the inserts, maintaining high process reliability.

Besides uncoated inserts, Guhring offers them with a TiCN or its Firex multilayer coating, Larson noted. While uncoated inserts are appropriate for nonferrous materials such as aluminum because aluminum can stick to certain coatings that have an aluminum base, TiCN is frequently selected to cut steel and Firex is desirable when turning difficult-to-machine metals to remove heat and keep the workpiece material temperature in a machinable zone.

When an insert reaches the end of its tool life and must be changed, Larson added that Guhring toolholders have a priority locating mechanism that aligns the cutting edge of the insert identically each time. "You can put a new one in, and it is going to sit in the exact same spot as the previous tool because they are all located off of a pin system at the back of the toolholder."

Something special

Even with an extensive selection of standard tools, manufacturers frequently must engineer and produce customs. "It is extremely common for customers to require special internal grooving tools," Larson said, especially as the complexity of forms continues to increase. That might involve a special clearance angle or width.

Guhring territory managers work with customers to gather the specific requirements, he added, and once an agreement is reached it takes about four to six weeks to deliver a special.

Greenleaf's Dillaman concurred that the need for specials is common. "Almost half of our business is related to special design projects. We have an experienced engineering team here, and they receive requests on a daily basis for different applications."

The process starts by acquiring information from a customer, Dillaman said, including drawings and models to help develop the full tooling package. The customization process is a collaborative effort with a customer's manufacturing engineering team to achieve the highest metal removal rate.